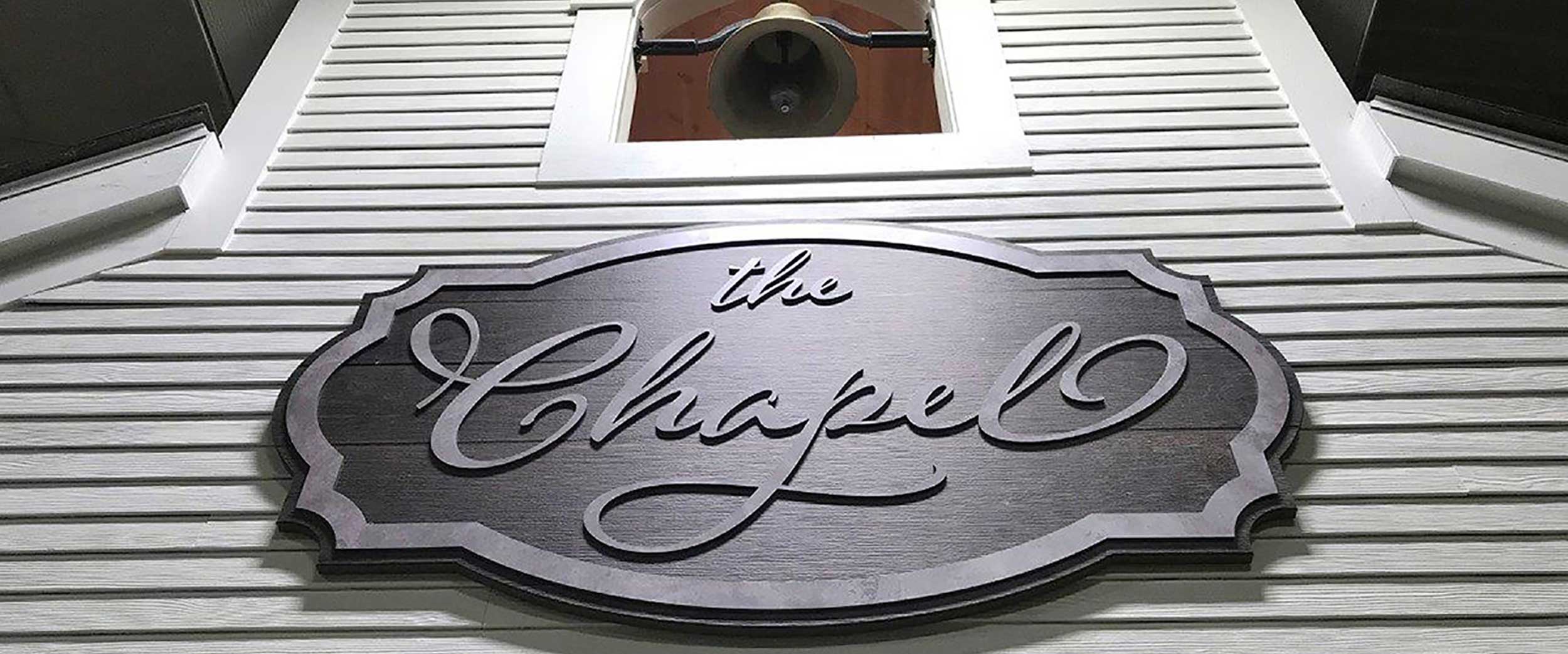

NOTHING BEATS GOOD ol’ wood as the basis of a sign. That’s what a lot of signmakers say, but is that really the case? Wood requires a lot of work to finish into a smooth surface, grain and knots can vex the most skilled carvers, and without proper treatment, the elements can wreak havoc – not to mention, the final product can be heavy. Manufacturers are continuing to improve plastics and sign foams, and a number of new products hit the market each year. So let’s take a look at the latest trends, and you can decide if they will fit into your projects.

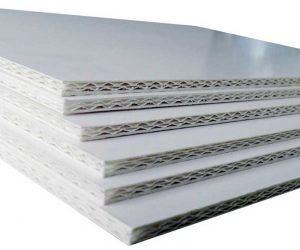

While we talked about wood being a favorite of signmakers, aluminum ranks up there as a near second. However, aluminum sheeting has issues as well. If you use a UV printer for direct imaging, it is possible that the lamps can warp the sheet. A great solution is a sandwich of a PVC core between two thin aluminum sheets. This provides the surface your customer wants and adds significant structural stability.

Also, you often see cool, digitally printed, digitally finished three-dimensional displays. If you have the equipment, then you may be trying to figure out what material to use to create them. You may need hot or cold formability for curves and fold-overs, but you definitely need a smooth printable surface. How about two PVC sheets surrounding a foam core? It will solve all of your problems and offers a great alternative to cardboard.

If dimensional needs are not an issue, you can find foamcore boards that are treated for direct printing. They offer smooth, bright white finishes and in most cases can be easily cut with a finishing machine or by hand.

What about substrates for backlit signs? Acrylic is a common choice. Typically, one would apply printed clear film to the sheet and mount it in a light box. We are now seeing acrylic sheets that are coated on one side to accept direct printing. This saves cost on media and cuts out a production step. The non-printable side is typically abrasion- and chemical-resistant in order to help protect from outside elements and graffiti.

Sustainable Choices

Now we get into the more serious part of the discussion. For all the benefits seen with plastics and foams, there is also potential environmental irresponsibility. In other words, how do you get rid of the stuff after it has served its purpose? Luckily, we are seeing a trend toward environmental accountability. Take, for example, new products that use paper as a core as opposed to some type of foam. They have many of the same properties, but are 100% recyclable.

Advertisement

The newest trend we are seeing is manufacturers who have a commitment to the environment via their own recycling programs. This, along with growing consumer demand for such sustainable practices, is sure to inspire more green plastics, foams and recycling programs around the country and the world.

So as you see, plastics and foams are getting better and better. With a focus on printability, flexibility in construction and now a growing commitment to sustainability, we can’t wait to see what’s next for the new decade.

PHOTO GALLERY (6 IMAGES)

Tip Sheet2 days ago

Tip Sheet2 days ago

Business Management1 week ago

Business Management1 week ago

Women in Signs1 week ago

Women in Signs1 week ago

Real Deal3 days ago

Real Deal3 days ago

Editor's Note7 days ago

Editor's Note7 days ago

Maggie Harlow2 weeks ago

Maggie Harlow2 weeks ago

Line Time1 week ago

Line Time1 week ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago