When we examine the basics of reflective markings, nighttime traffic safety should be the primary objective. Nearly 70% of all fatalities occur at night. People wrongly assume that reflective markings on the rear of a vehicle provide all the necessary nighttime identification.

Nighttime safety

The fact is, nearly half of all car and truck collisions are "T-bones." Moreover, these types of crashes account for more fatalities and greater property damage. Nearly all of these collisions result in some injury to the car’s occupant. (Jayne Mansfield’s death comes to mind.)

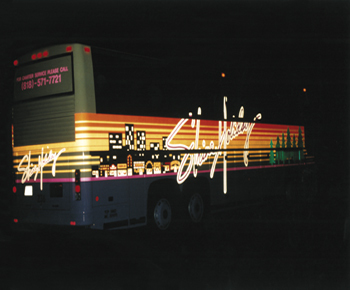

Imagine a large truck slowly turning in a poorly lit intersection and a speeding motorist approaching the intersection. Drivers need ample warning, and side reflective markings that decorate the vehicle’s full length help to alert them effectively.

National Highway Transportation Safety Administration (NHTSA) and the Federal Highway Administration (FHWA) regulations require any carriers engaged in interstate commerce to use either red-and-white retro-reflective striping (which reflects light back to its source) or reflex reflectors on the sides and rear of tractor-trailer units. These regulations cover semis, flatbed trailers and tankers with a gross vehicle weight over 10,000 lbs. The rules also cover any tractor weighing more than 2,032 lbs.

Simply put, nearly every fleet vehicle that travels anywhere must have this striping, commonly referred to as "conspicuity markings." Red-and-white markings must cover at least half the length of the sides of trailers and tractors, and must also be applied to the underside protector or bumper on the rear of the trailer. Tractors must also have reflective material applied to the bracketing system for mud flaps.

Advertisement

High-intensity reflective striping is an important part of any fleet-graphics program. These stripes tell the motorist the unit’s length and help determine the mass and shape of the unit. By using highly reflective colors and positioning markings at a height where headlights show the greatest reflective brilliance, motorists can see the vehicle more quickly. This advance warning gives the motorist enough time to recognize the impending danger and react appropriately.

According to NHTSA research, reflective conspicuity markings provide drivers with the needed warning to avoid accidents. Government research estimates that nearly 8,000 accidents are prevented annually in the United States due to these markings. Avoiding these accidents prevents $5 million in property damage losses every year. Further, the NHTSA estimates that conspicuity markings have reduced rear collisions by 25%, and side-impact collisions by 15%.

Reflectivity basics

When I started in the business, reflective sheets worked like mirrors. Appropriately, these products were called "mirror-reflective." However, mirror-reflective film’s biggest shortcoming allowed motorists to see only reflective light when the headlights were perpendicular to the vehicle surface. At any other angle, the light reflected in the opposite direction, into the oblivion of the night.$image1

Current reflective sheeting features the unique characteristic of retroreflection. Two types of retro-reflective sheeting are available: enclosed-lens, glass-bead sheeting, and microprismatic — or "cube-corner" — retro-reflective material.

"Glass bead" sheeting features a complex construction of many laminated layers. Thousands of microscopic glass beads are embedded per square inch in these layers. Sandwiched between the adhesive and the bead layer, a metalization layer is closely molded to the contoured backside of the beads, and acts as a reflector. Light passes through the film’s top layers and strikes this layer. Bouncing off the metalization layer, light returns through the beads back to the light source.

Advertisement

Rather than glass beads, microprismatic reflective material uses an embossed geometric pattern on the sheeting’s interior surface to refract the light beam. By bouncing the light off different planes of the pattern, the light is redirected back to its origin.$image2

Various reflective film types and colors are available from manufacturers such as |1303|, |2109| and |1927|™. Years ago, the color selection for reflective sheeting was limited to approximately 10 colors. Today’s designers can choose colors like new gold, tomato red, burgundy, light blue, purple and Kelly green.

Your selections should match the physical characteristics and budget of the intended application. Consider the substrate to which the markings will be applied.

Some reflective products can only be applied to flat surfaces. Stiff sheeting used for conspicuity striping won’t conform to rivets. When applying these types of products, the film must be cut around the rivet head; special cutting tools have been developed for this application. Using the proper installation tools and techniques, softer reflective films conform to rivets, corrugations and other irregular surfaces.

Standard Descriptions and Classifications for Retro-Reflective Sheeting

Description ASTM* Classification Product Classification and Typical Candlepower

Rating for White Reflective Sheeting

Utility grade N/A Used for short-term promotional projects and stickers.

Candlepower rating: 30 to 69

Medium intensity (engineering grade) Type I (enclosed-lens, glass-bead sheeting) Used for computer sign cutting and screenprinted fleet identification markings.

Advertisement

Candlepower rating: 70 to 139

Medium-high intensity (super engineering grade) Type II (enclosed-lens, glass-bead sheeting) Used for highway and construction signage.

Candlepower rating: 140 to 249

High intensity Type III (encapsulated, glass-bead retro-reflective material) Used for highway and construction signage.

Candlepower rating: 250 to 399

High intensity Type IV (unmetallized, microprismatic, retro-reflective element material) Used for highway and construction signage

Candlepower rating: 250 to 399

Super-high intensity Type V (metallized, microprismatic,retro-reflective element material) Used for conspicuity striping and vehicle safety markings. Candlepower rating: 700 to 1,300

*ASTM is an acronym for the American Society for Testing and Materials.

Tip Sheet4 days ago

Tip Sheet4 days ago

Business Management2 weeks ago

Business Management2 weeks ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Real Deal5 days ago

Real Deal5 days ago

Benchmarks17 hours ago

Benchmarks17 hours ago

Editor's Note1 week ago

Editor's Note1 week ago

Line Time2 weeks ago

Line Time2 weeks ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago