Electricity and water simply don’t mix — every child knows this. Neon-sign professionals also know that electrical installations in damp or wet environments require special care — especially those that operate at high voltage. Because neon and cold-cathode sign and lighting installations employ high voltage, wet environments require designated materials and installation procedures.

Whether snow is melting in the North, or it’s the rainy season in more tropical climates, spring is a wet time of year. Service calls made during this season often unveil weather-related sign problems usually caused by improper installation. Environmental conditions determine materials and construction when engineering a neon sign.

In some cases, electrical regulations — especially the National Electrical Code’s (NEC) Article 600 — stipulate additional requirements to address such conditions. Not all sign parts necessarily need to be weatherproof. For example, if an outdoor sign’s neon transformer is installed in a dry, warm, indoor location — with the GTO and conduit penetrating the "wet" wall — an indoor transformer may be suitable. So, I will discuss the dampest scenarios, and the installer may reduce the requirements — provided they comply with the electrical inspector’s rulebook.

Corrosion

Sign-material deterioration (especially iron) always correlates with water. Heavy-duty galvanizing works only if zinc completely covers the surface. Also, no metals, besides zinc, can directly contact the galvanized surface at a spot where humidity may occur. Other metals cause electrochemical corrosion. NEC Article 600.8(D) dictates, "Metal parts of equipment shall be protected from corrosion." Thus, never use stainless steel or chromated sheetmetal screws outdoors to fasten galvanized iron.

A solid layer of paint also provides good protection against metal corrosion. Be sure to remove the paint at every bonding connection to ensure a secure, positive ground connection. Water can also corrode plastic materials. Water exposed to UV rays may turn into hydrogen peroxide (bleach), which attacks the plastics’ polymeric structure.

Any sign enclosure mounted outdoors — even under a canopy or roof — must have drain holes 1/4 to 1/2 in. wide at every low point or isolated low section. Further, the drainholes must be situated to avoid external obstruction.

Transformers

In the sign industry, neon transformers are divided into three usage classes: a) indoor (dry, non-condensing); b) outdoor, non-weatherproof (dry, may handle condensation but no dripping or spraying water); and c) outdoor-weatherproof (can withstand rain on its surface). Though a few manufacturers may claim otherwise, my experience has shown that electronic, neon power supplies — especially those that operate with more than 2,000V — are unsuitable for outdoor use.

High frequency and high voltage, combined with humidity, significantly increase the effects of capacitance; water’s high, dielectric constant increases capacitance by a factor of eight. Capacitance must be minimized when using electronic power supplies. Moreover, these conditions also generate corona and ozone far more often than line-frequency high voltage. Thus, for a reliable, outdoor, neon installation, use only magnetic transformers.

After UL 2161 secondary ground-fault protection took effect, tripped protection circuits spurred many service calls. If the protection keeps tripping on wet days, something is wrong with the installation. This is hard to swallow, but it’s true. In most cases, GTO has deteriorated; water has entered the housings, or debris (spiders, bugs, bird droppings, etc.) has created a shortcut for the electricity to ground.

Also, verify that the sign is properly grounded (check for rusted screws on bonding jumpers) and that line conditions are compliant. A high-resistance ground and a higher leakage current can raise the voltage between ground and neutral to a level that causes most protections to trip. A checkup of electrical conditions may save you (and the client) some sleepless nights.

Make the right choice

Only outdoor-weatherproof transformers may be installed without any additional outdoor protection, as the rating implies, but they’re difficult to find. Most transformers, which belong in the outdoor, non-weatherproof class, must be installed only outdoors inside an additional enclosure, such as the sign body or a transformer box that protects the transformer and terminals from direct weathering. Note that the transformer box or the sign body must be listed, or designed, for the outdoor application. Be sure to mount the transformer box correctly; it must be well fastened and correctly orientated so that dripping water never enters the box.

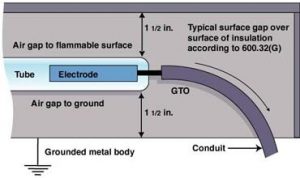

To prevent transformer protections from erratic tripping, observe all air and surface spacing requirements (Fig. 1). The NEC 2005 maintains distinctions between wet and dry locations. Per rule 600.32(G)(1 and 2), GTO must extend 21/2 in. beyond conduit in dry locations before a connection is made. Wet locations require a 4-in. GTO span past conduit. It’s well known that polymeric insulation ages over time and is more prone to hold moisture. Thus, in my opinion, longer GTO is safer.

Electrode connections

Improper electrode connections often cause electrical inspectors to disapprove outdoor signs. Wet locations require special products and procedures. First, all electrode receptacles — cups, boots, insulators, etc. — must be wet-location listed.

For many years, glass has proven to be the best long-term insulation material for high-voltage, outdoor signs. The problem with standard electrode receptacles is that water could enter the sign body through the front opening. Wet locations require watertight cover bushings, which are normally plastic. However, plastic materials age, so this won’t provide unlimited protection. Where applicable (most often for border tubing), install double-back electrodes using listed, glass, electrode connectors (cups).

Available in different shapes and sizes, they may interconnect electrodes or connect electrodes to GTO with or without a wall GTO feedthrough. Note that all cup-style glass insulators must be orientated to a 45

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery2 days ago

Photo Gallery2 days ago

Ask Signs of the Times4 days ago

Ask Signs of the Times4 days ago

Real Deal1 week ago

Real Deal1 week ago

Benchmarks6 days ago

Benchmarks6 days ago

Editor's Note2 weeks ago

Editor's Note2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago

Photo Gallery1 week ago

Photo Gallery1 week ago