Business Management

Crunch the Numb3rs

Published

14 years agoon

Yes, you make money because you understand your customer, and you create a good perception to create value. But what do your customers always ask about? The price.

The other P’s (product, place and promotion) accrue costs that hopefully create value. The price should recapture this value. Yet, many sign companies adopt simple “rules of thumb” as their pricing strategies, because those prices have kept them in business, and, rather than apply for a CPA license, they’d like to spend most of their time creating good signage.

What do flourishing sign companies always ask about? The costs. They set a selling price that covers production or wholesale costs, freight charges, a share of overhead (fixed and variable operating expenses) and a reasonable profit. Other cost factors, such as insurance rates; shrinkage (wasted materials and mistakes); seasonality; shifts in wholesale or raw material prices; and sales or discounts affect pricing. Also, some costs – capitalized as assets – such as startup costs, equipment and improvements, can be amortized.

In a downturn, small businesses are tempted to knock down the price to win a sale. Don’t cave in. Set a firm line based on solid business tactics, not on negotiating skills. Never compete on price alone. If you do, your profit margins will be slashed by ever-mounting costs. Even if you do make a slight profit, you’ll smolder with resentment for working so hard for so little.

At the other extreme, avoid the “coffin corner of costing,” where CPA-like tunnel vision values capacity production rather than high value. Price cutting signals customers that you‘re an easy prey for additional discounting. And it may cloud your brand‘s hard-won image.

Instead of trying to please all people in all ways, specialists who build a strong reputation as, say, gilders, focus on the market segment they serve best. Their business-management plans involve budgets, but they aren’t based solely on costs.

Plug revenue leaks

Sign companies can run aground by not recovering all the costs involved in their services. With quantity jobs, set minimum-order quantities so that processing costs won’t eat the profits. Strengthen collection efforts to shrink the time between orders and receipt of payment.

Drop unprofitable services that entail high customer-service and maintenance costs. Also, don’t offer services your customers don’t want, even though you just can’t force yourself to give up. When was the last time your customers wanted showcards, yet you struggle to put down that brush?

If you don’t track the details, the big picture becomes cloudy. Set up a business-management system that can track such concerns as what department ordered the wrong type of aluminum for a job and pinpoints where all that material is being wasted.

In lieu of your own, automated system, investigate the business-management software sold by such companies as ABC Sign Products (Ft. Collins, CO); CASper/Easynet (Jenkintown, PA); Cyrious Software (Baton Rouge, LA); CRC Information Systems (Scottsdale, AZ), Datacom/dataSIGN (Bloomington, MN), EstiMate Software (Asheville, NC), Identia (Needham, PA) and Sign Tracker (Austin, TX).

No matter how cost-conscious you become, don’t forget what your clients need – outstanding signage. ST asked several sign companies that entered the Inter-national Sign Contest to briefly outline costs that factored into their pricing strategies for their entries. Some balked at disclosing prices, especially for channel letters, because they didn’t want to give competitors a leg up on upcoming bids. Read further, however, to see how four brave souls fared.

Overall profits

For this flag-mounted, ID sign for the Denim33 clothing store in Greensburg, IN, Green Sign Co. (Greensburg, IN) employed relief carving and dimensional letters to create a jeans-belt-buckle look. Two, 1-in.-thick, routed, Sign•Foam HDU, sandblasted signs feature painted, Matthews acrylic polyurethane, brushed aluminum with a 1-in. nylon rope inset in the signs and painted to match. Standoffs, painted black, project the 0.125-in.-thick, routed, aluminum letters, painted with Matthews black; mounting-pole hardware and installation were included.

Shawn Green, Green Sign’s CEO and president, said, “We have standard prices in Cyrious software for most sign series that we sell. For customer-shaped signs like this job, we use an Excel spreadsheet originated by Dan Hale [I highly suggest all sign companies take his class] to calculate actual materials, labor, hardware, installation and overhead. Our estimate/budget included $957 in materials and 28 work hours. The job, which sold for $3,100, came in under budget on hours and a bit over on materials. This job yielded a 9.72% profit.

“All of our profit-and-loss reports deduct overhead from the actual profit, which makes it real. It keeps us mindful of overhead, because this can be a secret killer to your profit. We share this information with all of our crew.”

Magnificent moo-la

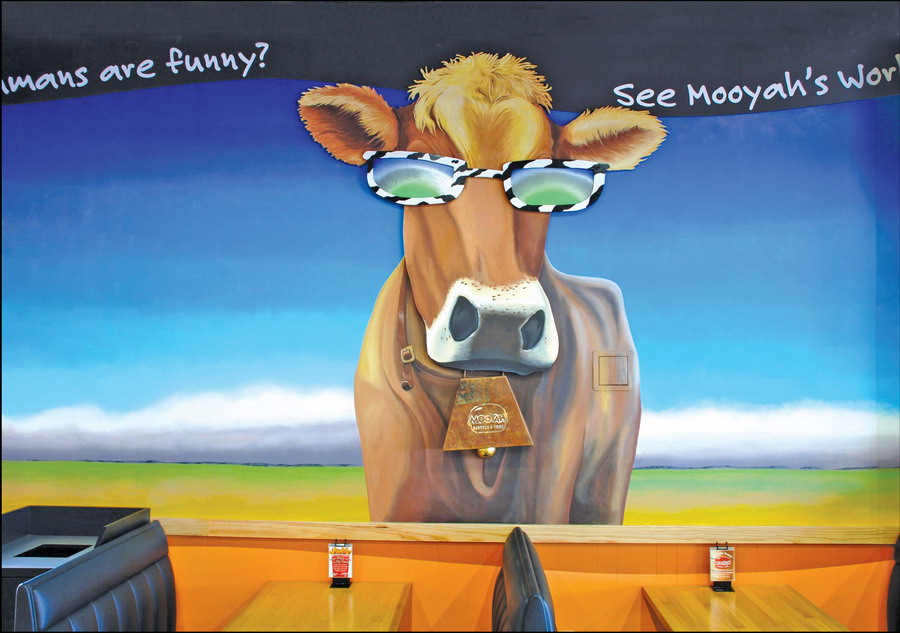

Great Big Signs Inc. (GBS), Kyle, TX, can’t help itself. GBS designer Lynn Wilkerson and partner Mario Munoz’s work just has to make a unique statement. That’s why Mooyah’s Burger & Fries asked the company to create colorful, engaging graphics for the quick-casual restaurant chain.

Wilkerson said, “One of the biggest challenges in developing the artwork and color scheme was to give the restaurants a branded look with the same elements tailored to fit each individual retail outlet.” He worked with existing logos and brand elements, and added color and character with a cow in sunglasses.

For the restaurant interior, Wilkerson and freelance designer Devon Hanna created the color palette from photographs of the restaurant’s burger and applied them via printed media and paint. The design elements were printed on vinyl and installed by Lewis Sign Builders (Buda, TX), using an HP printer and 3M vinyl, which was contour cut on a Summa plotter. After the walls were painted solid colors, the contour-cut graphics were applied to the background.

GBS prototyped three stores with simple, original and distinctively Mooyah! characteristics and colors that would be easy to reproduce. The GBS team added the handpainted cow and the black-vinyl, undulating, descriptive copy around the ceiling. The 3-D copper cow bell is handcrafted from copper sheeting cut and welded to shape. The cow-bell clapper is a brass doorknob. The image was photographed and reproduced for future locations.

The $17,000 selling price entailed hiring two men and one day for location work for painting, pictorial and vinyl-installation work. Pricing was based on square footage, vinyl charges and materials marked up 18%. The customer paid location expenses.

Harboring good will

Jackson Smart, proprietor of Jackson’s SignArt Studio (Port Angeles, WA), has created many signs that celebrate the history and natural wealth of his home base. The arrival of the first European ship, the San Carlos from Spain, which entered the deep-water harbor in 1791, is portrayed in this welcome-sign/mural as the ship is greeted by the S’Klallam Native Americans. In the early years after their discovery by the Royal Navy’s Captain George Vancouver, the area’s abundant forests, whaling and salmon fishing attracted booming, pioneering business.

The 10 x 20-ft. mural, created in 2009, comprises ¼-in.-thick Alupanel. The scene and letters, painted with Cel-vinyl and Nova color acrylics, were triple clearcoated with Cel Vinyl clear. The sign was painted inside the studio and then installed on the wall of the Black Ball Ferry Building, where it faces north, 75 ft. from the water, directly across from the Black Ball ferry (an international gateway from Victoria, BC, Canada).

Smart doesn’t price by square footage. “From experience, I usually know how to price a project. Because this was for the city, which was funded by City of Port Angeles Lodging Tax Revenue, and I’ve done several big projects for the city, I knew their budget. This project penciled out to $11,175. So, for a square-foot comparison, it was $55.85 per sq. ft.”

The project also included an interpretive sign, for which Smart provided the artwork to Windsor FireForm (Tumwater, WA). This shop completed it on a porcelain-enamel panel and a powdercoated pedestal. Smart mounted it on the sidewalk, next to the mural.

This was Smart’s second welcome sign for the waterfront. He had completed the first, Welcome to Port Angeles sign in 2004 on the east entrance of town (see ST, September 2006, page 38). The third welcome sign is scheduled for the west entrance on U.S. Rte. 101, coming in from the Pacific Coast.

Rx for installation issues

Andrea Vacanti, president of Vacanti’s Extreme Signs (Fredonia, NY) designed a fairly straightfor¬ward, 2 x 15-ft. apothecary sign from 1½-in.-thick Sign•Foam HDU gilded with 23k Manetti looseleaf gold and painted dark green with Ronan Aquacote.

However, the building face didn’t offer a flat area to mount the sign. Thus, Andrea designed the graphics to be carved, and William Vacanti, Extreme Signs’ VP, fashioned, a 2-in., angle-iron steel frame 6 in. smaller than the sign to hold three, 2 x 8-in. backer boards that were bolted to the steel framework,. He then glued three, 4 x 1-in. support planks to the backside HDU using West Systems’ two-part epoxy for additional support.

After having mounted the steel framework to the building face using a combination of Tapcon anchor bolts and expandable rivets, the Extreme Signs crew then mounted the HDU to the 2 x 4-in. backer boards with deck screws and covered the screw heads with Aquacote.

Andrea said, “The installation may seem like overkill, but I know it will be there for years to come, and I won’t have to address any installation issues in the future with this sign. To us, it’s worth the extra time and effort to do it once – build it strong – and not have any callbacks.”

Factors that determined the selling price were: building the support framework; the labor involved for the goldleaf gilding and the cost of the goldleaf; two coats each of paint and primer; the complexity of the installation, which required a bucket truck and three men; and the carving costs. The 7.75% NY state sales tax was applied.

The project entailed approximately 12 to 18 hours for painting and gilding, and eight hours for the construction of the support framework. They also included travel/driving time to the site with equipment.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Fiery Releases SignLab 11

21 Larry Albright Plasma Globes, Crackle Tubes and More

2024 Women in Signs: Christine Hykawy

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet2 days ago

Tip Sheet2 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management1 week ago

Business Management1 week agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal3 days ago

Real Deal3 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Editor's Note7 days ago

Editor's Note7 days agoWhy We Still Need the Women in Signs Award

-

Maggie Harlow2 weeks ago

Maggie Harlow2 weeks agoThe Surprising Value Complaints Bring to Your Sign Company

-

Line Time1 week ago

Line Time1 week agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines