Digital Printing

Gerber Solara UV2

Shining Brighter

Published

18 years agoon

Gerber Scientific Products has been a standard in the sign industry for as long as we can remember, and their hallmarks have always been innovative design and outstanding quality. The Gerber Edge has been a de facto standard for printing images on vinyl.

Though the Edge, in its latest incarnation, is still an incredible product, the industry has been changing by leaps and bounds. The trend has been towards wider materials, photographic quality and expansive substrate choices.

UV printing continues to be the hot printing technology that's sweeping the sign industry these days. This technology is environmentally friendly, and the inks can adhere to virtually anything. A UV printer with an adjustable head height can even image rigid materials.

Unfortunately, the early UV printers were extremely expensive, ranging in price from $150,000 to more than $500,000. To further limit choices, the printers were generally designed to handle rigid material, due to a flatbed design, or to handle flexible, roll-to-roll media. Hybrid printers that could do both were scarce and very expensive.

Gerber saw that change coming and, not so long ago, introduced the Solara UV printer. This product offered roll-to-roll printing using a unique set of UV inks. The machine's price made it affordable to medium-sized shops, but the roll-only design limited its use to more traditional sign applications.

Gerber realized a hybrid design would tremendously benefit the sign industry, and it answered with the Solara UV2. This second-generation UV printer melds the best features of the Solara UV with an ability to handle rigid materials. At a list price of $67,995, the Solara UV2 is attractively priced for shops that want to expand their product offering, while still performing many traditional digital-imaging functions.

Specifications

We examined the Solara UV2 in detail at the 2006 ISA show in Orlando. At first glance, it still had the Solara UV's beefy build, but it also now has front and rear roller tables.

The printer is designed to handle both flexible and rigid media up to 60 in. wide. The actual printable-image width is 591⁄2 in. With the tables attached, this printer is fairly large. With the roller tables detached, the printer is 109 in. wide x 57 in. high x 33 in. deep. When the roller tables are attached, the printer's depth grows from 33 in. to 181 in. (more than 15 ft.).

Gerber suggests leaving at least 3 ft. of space around the well-built and solid printer to accommodate operation and media handling. Expect to have Gerber install this 800-lb. printer at your shop.

Other than a fairly large workspace, its only other special requirement is for power. The printer operates in a power range of 220 VAC +/- 10% at 50/60Hz. It draws 20 amps. Gerber includes a line conditioner that ensures clean power to the printer. The workspace should also maintain a temperature of 65 to 85° F with a humidity range of 40 to 60% RH non-condensing.

Printing specifications

Hopefully, everyone who reads our columns is familiar with UV-cure-printing technology. For the new reader, here's a quick recap. UV-cure ink is formulated to stay liquid until it's exposed to UV light. When exposed, the ink hardens and dries. The very durable, cured image offers up to three-year outdoor life without lamination.

The ink characteristics allow them to be used with piezo-inkjet head technology. The major modification to a standard inkjet printer is a means of curing the ink. Typically, a UV light source is attached to the printhead carriage, which allows the ink to cure as it hits the media.

AdvertisementThe Solara UV2 uses exactly this technology. The six-color printer has one head per color. Two UV lamps, integrated into the printhead carriage (Fig. 1), preheat the media and cure the ink as it's printed. Printhead resolution is 300 x 360 dpi, but the apparent resolution is 600 dpi.

Gerber uniquely addresses color gamut and image quality. Instead of the traditional cyan, magenta, yellow, black, light cyan and light magenta, the Solara UV2 uses cyan, magenta, yellow, black, violet and green. The odd secondary colors, Gerber says, allow the printer to achieve much better reds, greens and oranges than traditional digital printers.

Gerber realizes its customers are signmakers and graphics providers who want vibrant, crisp colors for their customers. The printer also utilizes multi-drop technology with a multi-level pallet that also prevents dot gain.

As for speed, the Solara UV2 tops out at 75 sq. ft./hr. in two-pass mode. The typical shop will commonly use three-pass mode at 50 sq. ft./hr. For the best quality (six-pass mode), the output speed is 25 sq. ft./hr.

The Solara UV2 comes equipped with a 10/100 Ethernet interface as a means of connection. It uses TCP/IP protocol, which has become the standard in most offices and sign-shops. The printer can be connected to a local area network, or it can be directly connected to the RIP server via a special crossover cable.

Inks and media

The ink comes in 230ml cartridges (Fig. 2) at approximately $75 per color. The printed image will last up to three years outdoors without lamination. Gerber offers roll media but not rigid substrates.

However, it has profiled approximately 15 different media types, including vinyl, mesh, Coroplast corrugated, twinwall plastic and even MDO. The profiles ensure no additional tuning is needed to obtain the best-possible image quality.

AdvertisementNotice the list of media includes some rigid materials. The first Solara UV only handled roll media. The head height can be adjusted to handle media thicknesses up to 0.5 in. We'll examine how this is done a little later.

Software

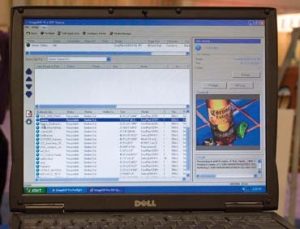

The purchase price includes a Gerber-specific copy of Onyx ImageRIP Plus (Pro is also available) (Fig. 3). You'll need at least a Windows 2000 Professional (Service Pack 4) or XP Professional system with a minimum of 1GB of RAM and a 40GB hard drive. A Solara UV2 driver, as well as media profiles, are included.

Printer operation

Ease of operation characterizes the Solara UV2. Any device too difficult to operate can become an expensive boat anchor that will only be used occasionally.

We've seen numerous UV printers. In most cases, the roll-to-roll machines are fairly straightforward and easy to use. Ones that handle rigid materials, especially the hybrids, are a different story.

With rigid material, you must adjust the head height and ensure the roller tension is set correctly for the media, and that the media is positioned properly for feeding. Changing from rigid to flexible necessitates removing tables, loading media, readjusting everything… well, you get the picture.

Gerber has engineered a very easy-to-use solution. Let's look at loading rigid material. First, we compliment Gerber for supplying two heavy-duty roller tables. They're solid; the rollers are fluid, and the size can easily handle a 4 x 8-ft. board.

The tables are also designed for easy removal or installation (Fig. 4). Casters allow one person to roll the detached tables into place. Positive locks ensure proper leg deployment. Two latches easily and precisely secure the tables to the printer.

Removing the tables for roll-to-roll printing is also simple; just unlatch the table. Release the leg locks, and roll the table away. The back and front tables are easily distinguished. The rear table's metal guide positions the media prior to printing. This is much easier than a system with only a mark to line up the media. The guide is long enough to ensure the media is straight.

With the tables in place, it's time to load the media. First, the lamps must be raised to the high position. There's only a high (for rigid media) and a low (for roll media) position, which is adjusted from the front of the printer.

Next, you raise the media rollers with a single, large and easy-to-find handle. The rollers are adjusted to low force by turning wheels on the roller assemblies. You can adjust the gap between the heads and the platen using the wheel located on the printer's side.

The first piece of media can be loaded from the rear of the printer. Simply align the media's right side with the media guide, push the media under the rollers, and adjust their position if necessary. Engage the media-load lever, and use the wheel for final adjustment. Turn it clockwise until the audible chirp stops. Turn the lever counterclockwise one complete turn, and you're ready to print. While this may sound complicated, it's actually easy and fast.

One person can easily operate the printer. To print on roll material, just remove the tables, adjust the lamp height, reset the rollers and media thickness, and load the roll.

The versatile Solara UV2 is built with signmakers in mind. With it, you can produce full-color banners and signs (Fig. 5) by either printing directly on the final material or printing on an adhesive vinyl and then applying it. The controls are easy to adjust, and registering rigid materials is virtually a no-brainer.

Although $67,995 sounds like a lot of money for a printer, it's one of the best-priced, UV-hybrid machines on the market. It comes complete with everything, so you can start making money quickly.

Gerber Scientific Products

83 Gerber Rd.

South Windsor, CT 06074

(860) 643-1515

Fax: (860) 648-8360

www.gspinc.com

Contact: Sean Childs, product manager

Company Profile: Since 1980, Gerber Scientific Products has supplied the signmaking and specialty-graphics industries with printers, software, plotters, routers and supplies.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet4 days ago

Tip Sheet4 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management2 weeks ago

Business Management2 weeks agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal5 days ago

Real Deal5 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks1 day ago

Benchmarks1 day ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note1 week ago

Editor's Note1 week agoWhy We Still Need the Women in Signs Award

-

Line Time2 weeks ago

Line Time2 weeks agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines