LEDs + Lighting

HID 101

Published

14 years agoon

High-intensity discharge (HID) lighting systems illuminate most architectural and billboard installations. HID’s energy-saving features have traditionally made it the most popular system for street lighting. An HID lamp is roughly two-and-a-half to three times more efficient than the best, production LED.

Even if these lamps seem foolproof, their proper use isn’t. Also, in the past 10 years, many different types and systems have emerged on the market, so it’s time to point out a few HID characteristics to observe before problems arise.

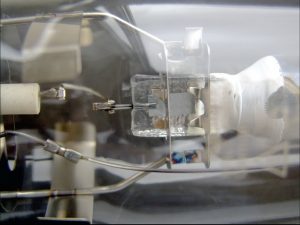

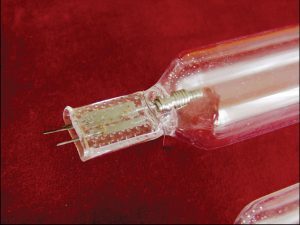

All HID lamps are so-called arc lamps (they are classified as gas-discharge lamps), where the electric arc is generated within a defined atmosphere of gases and vapors. Confining the arc in a rather short (the electrode distance is 1⁄10 to 4 in.), transparent, heat-resistant quartz-glass or ceramic container produces the high light intensity. The electrodes, which are thermal emitters (they’re not preheated), mainly comprise wire coils or pinpointed pure or doped-tungsten rods.

Because the gas or vapor pressure inside the lamp is, in most cases, higher than atmospheric pressure during operation, an outer glass envelope protects most lamps from an explosion and UV damage.

I won’t be covering rarely used types of HID lamps, such as super-pressure mercury or xenon arc lamps, because they’re used only in very special applications. Just keep in mind that super-high-pressure lamps can explode worse than a grenade. Always protect the lamp and yourself when working with this type.

HID history

Historically, the high-pressure, mercury-vapor (HPM) lamp reaches back into the 1940s. Pure mercury generates a pale-blue light; its most intense radiation lies in the ultraviolet spectrum range. The visible radiation comprises a green and blue line, which yields a very bad color rendering.

Pure-mercury lamps were contained in large, glass bulbs, which later were coated on the inside with a red, fluorescent material, which added red light to the emitted spectrum by using some of the UV radiation. These lamps, which were widely used in industrial lighting, were sometimes nicknamed “dinosaur eggs” or “elephant eggs” because of their shape.

Their low price, wide availability and long life makes HPM lamps still popular for industrial space lighting and billboard lighting where color rendering isn‘t important.

The most frequently used HID lamp for street lighting, the high-pressure sodium lamp, emits the widely known yellow-orange light, which produces distinguishable colors that aren’t rendered correctly (compared to the pure-yellow, low-pressure sodium lamps, where all colors look grey-yellowish-green). Because of this, they’re not used in the sign industry.

When unlit signs are illuminated by stray light from streetlights, the signmaker should consider how the color combination appears in this light. High-pressure sodium is one of the most effective lamps – up to 141 lumens/watt, compared to roughly 40 lm/W for a good, white-LED module.

Mixed-media, halide-discharge lamps have been developed from the high-pressure mercury lamp to improve color rendering while maintaining intensity and efficiency.

Considerations

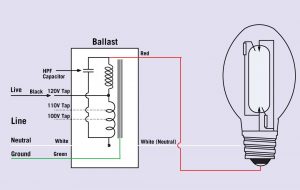

For any HID lamp, the ballast must be matched to the lamp type. Not only should the wattage match, but the ballast must be designed for the lamp. Ballasts are designed for only one lamp type (mercury, sodium or halide). Different fills bear different electrical characteristics, which the ballast must match.

An HID lamp’s operating current is the critical parameter. Lower current damages the lamp more than slightly higher current, because the electrodes don’t reach their proper working temperature.

Magnetic ballasts must be wired to the correct main’s tap, according to the real line voltage that’s measured at the sign location under load (always check with a voltmeter). Usually, the maximum permitted deviation is only +/- 3%.

HID lamps aren’t dimmable. A very few exceptions require special lamp types with matched, electronic ballasts. However, magnetic, ballast-operated HID installations must not be dimmed.

An HID lamp’s end of life is indicated by several effects. The lamp-operating voltage rises with lamp aging; each lamp manufacturer states a maximum operating voltage at the given current.

At the end of its life, the arc often becomes unstable (it wiggles and jumps from one spot on the electrode to another). Or the lamp color and brightness change remarkably. Another end-of-life indicator, blackening at the electrode ends (as in fluorescent lamps), is visible only in clear-envelope HIDs. Also, an opaque-white appearance at the electrode ends (especially with super-pressure lamps) indicates the quartz glass has begun devitrifying, and the lamp is subject to pressure rupture (explosion).

Never operate an HID lamp when the outer envelope is damaged, even if the inner bulb is still intact (and the lamp might even start).

As with some other lamp types (like tubular halogen incandescents), the lamp’s operating position plays a major role. In HID lamps, the electric arc reaches a temperature of several thousand degrees, and heat rises, as it does within the quartz bulb. If a lamp is designed for vertical operation, the upper electrode gets hotter than the lower one, which results in different electron emissions (we’re dealing with thermal-emitting electrodes here). So, if a lamp that’s thermally designed for horizontal operation (both electrodes dissipate equal amounts of heat) is operated vertically, the lower electrode won’t achieve the proper operating temperature; thus, the lamp will fail early.

When replacing HID lamps, not only should you replace the lamp with one of equal wattage, but also with the same starting characteristics. Otherwise the lamp and/or ballast can be damaged immediately.

Lamp-startup techniques

For HID, we can differentiate two lamp-startup techniques:

The pre-ionization or auxiliary electrode start. Here, the ballast doesn’t contribute to the lamp start. At least one main electrode in the lamp carries a tiny, auxiliary electrode nearby (usually on the side). A high ohmic resistance connects this auxiliary electrode to the other electrode.

When the ballast applies the power, insufficient voltage between the main electrodes can’t start the arc. But the electric field, in the small gap between the auxiliary electrode and its main counterpart, is strong enough to start a weak, glow discharge. The glow discharge generates enough ionized gas atoms, which are then accelerated in the electric field between the main electrodes, so that a heavy current can flow between them, and the lamp starts. In other words, the arc jumps from the auxiliary to the main electrodes.

Usually, this type of HID lamp can start only when cold, because the high vapor pressure in the hot lamp increases the starting voltage of the weak glow discharge over the applied voltage. Consequently, an auxiliary electrode-type HID must cool down for approximately 8 to 15 minutes before it can be restarted after having been switched off momentarily. For use with magnetic ballasts, the wires between the ballast and lamp can be as long as needed. For electronic ballasts, refer to the manufacturer’s recommendations.

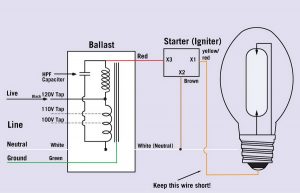

The trigger or pulse-start type. This type of lamp doesn’t start on its own; the ballast (or an additional igniter) must provide a high-voltage pulse or a pulse sequence between the lamp electrodes to start the gas discharge – similar to the high voltage needed to start a neon tube. Once the discharge is initiated, the low voltage, which the ballast can provide, will sustain the discharge.

When installing such lamps, the igniter or electronic ballast must be located very close to the lamp – often, wire lengths of less than a foot are specified. Otherwise, the igniter/ballast can be damaged, and the lamp won’t start properly. The start-pulse voltage can reach 3,000 to 4,000V (with some high-power, theatrical HID lamps, up to 20,000V). Thus, all wires and lamp bases must be rated for these high voltages.

Not all pulse-start HID lamps can be restarted while still hot. So, when replacing lamps in a sign installation, make sure the lamps are hot-restrike types if such lamps had been installed before. Cold-start lamp ballasts and igniters often bear an automatic time delay so they won’t be damaged by trying to restrike a hot lamp, which has to cool first.

To avoid an ingniter overload, pulse-start ballasts must be switched off when no lamp is in the fixture, or the lamp will be damaged and won’t start after a few seconds.

As with starter-type fluorescents, frequent on/off switching impairs HID lamp life. Thus, HIDs should be switched once per day to reach the average life, which is approximately 5,000 to 20,000 operating hours.

Regarding heat and mercury

With some tubular HID lamps, even the outer lamp bulb can reach temperatures that exceed 1,100° F and, thus, must not be placed too closely to flammable (or low-melt-metallic) material. However, the high temperature protects HID lamps from winter effects at low ambient temperature, as we know from fluorescent and argon-mercury neon tubes.

If you touch the outer bulb, wipe away fingerprints with a cloth dampened with alcohol so the prints won’t burn into the glass.

Most halide lamps also contain mercury and require proper disposal. If a lamp explodes, and the outer envelope breaks, the whole fixture must be carefully decontaminated, or the mercury will vaporize and contaminate the room when it gets hot while operating the next time.

Advertisement

Important Points to Observe When Using HID Lamps

• Check that the ballast and lamp wattage match.

• The lamp must be designed for the proper orientation (horizontal/vertical) in the fixture.

• A pulse-start type lamp must be operated on a pulse-start ballast/igniter.

• Make sure the lamp voltage is in the proper range (usually the maximum deviation is +/- 3%). Otherwise, use a different connection/tap on the ballast (if provided), or change the ballast.

• If the electronic ballast is dimmable, the lamp must also be designed for dimming.

• The connection between the starter and the lamp must be as short as possible.

• Use only hot, restrike lamps with proper starters designed for hot restrike.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery1 day ago

Photo Gallery1 day ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times3 days ago

Ask Signs of the Times3 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks6 days ago

Benchmarks6 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoWhy We Still Need the Women in Signs Award

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Megan Bradley

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More