Digital Printing

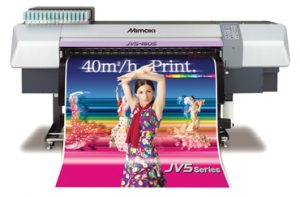

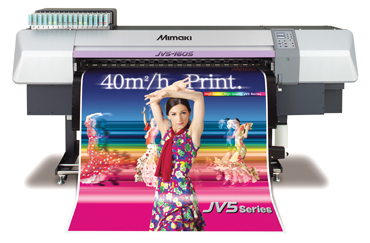

Mimaki’s JV5 Solvent Printers

Beautiful, fast and tough, Mimaki’s JV5 series delivers it all.

Published

17 years agoon

Innovation seems to be Mimaki’s hallmark, because it has one of the largest printer catalogs we’ve seen — the company produces flatbed and conventional, roll-based printers for dye, solvent, UV and sublimation inks. We’re equally impressed with its specific, niche-market products, such as control-panel prototyping. Further, although it’s not a niche product, we’re nicely surprised with its latest offerings: the JV5-130S and JV5-160S, machines made for the large-format, solvent-printing market.

When Mimaki’s engineers see an opportunity, they almost always deliver a product.

At first glance, the JV5-160S seems like plain vanilla, as opposed to Mimaki’s other whiz-bang printers. Its established, JV3 line features excellent solvent printers, so why bring out a new line?

Well, the JV5-160S is a totally different animal. It coalesces speed, quality and industrial construction into a production-shop printer. Stay with us, then, if your shop is looking to boost production while offering outstanding print quality, because we’re reviewing the JV5 series’ many technical innovations.

Specifications

AdvertisementMimaki offers the JV5-130S and JV5-160S. Their only difference is the printing width. The JV5-130S has a maximum printing width of 53.7 in., and the JV5-160S spans 63.7 in. Because of this technical proximity, we’ll refer only to the JV5-160S for the remainder of this review. As we mentioned earlier, it’s a solvent-based inkjet printer that images onto assorted media. More on this later.

You immediately see that Mimaki’s JV5-160S printer is truly built for the high-production market. You can’t help but notice the top-mounted, “at-the-ready” ink-cartridge array. To us, this big boy – it measures 122.9 x 41.4 x 60.7 in. and weighs more than 733 lbs. – looked like it could print 24/7 without stopping. The printer accommodates both 2- and 3-in.-diameter media rolls; total media weight can be up to 83.7 lbs.

The printer requires a 15-amp, 200- to 240VAC, 50/60 Hz, power supply. Its working-environment temperature edge is 68° to 95° F with a non-condensing, humidity-level range between 35 to 65%. It uses a USB 2.0 interface for its RIP connection.

Because it’s a solvent-based ink printer, the JV5-160S has a three- point, media-heating system that comprises pre-, print- and post- printing components. The first two ensure the ink’s media adherence, while the third speeds drying. An easy-to-use panel (Fig. 1) simplifies controlling the heaters.

Mimaki also offers an optional, external (infrared) heater, to ensure images dry at the highest printing speeds.

AdvertisementThe printing system

Basics aside, let’s examine the innovations, beginning with the heart of all digital printers: the marking [imaging] system. Mimaki has made a fairly obvious observation: to obtain high printing speeds, you have to sacrifice print quality. Lesser image quality isn’t a big issue for distance-viewed prints, but, if your shop specializes in signage for point-of-purchase, posters or bus shelters, you need reasonably high- quality images.

Mimaki’s wanted the JV5 series to make photorealistic prints at high production speeds. We can happily report its a success. The question is, how did they do it?

Easy. The JV-5 printheads have four times the number of nozzles typical of some other printers. It has eight lines of 180 nozzles (180 x 8 = 1,440) mounted in four printheads, as opposed to the typical four and two. This configuration provides 5,760 nozzles.

Consequently, the system lays down significant ink simultaneously, but this practice doesn’t necessarily translate to high speed. How did Mimaki’s engineers squeeze even more speed out of their design? They staggered the printheads. This strategy usually improves print quality, but here, it also supercharged the printing speed.

Advertisement

This works surprisingly simply. If we reexamine the typical printer, we find, normally, two printheads butted together, side by side. Consequently, the printhead tracks an approximate 1-in. swath across the media. With its staggered heads, the JV5 prints a 4-in. swath in a single run (Fig. 2) and thereby gains a speed advantage over conventional printers. See it like painting with a wider brush.

What about print quality? Remember? High speed and high quality were the engineer’s goals for these printers. Sure, the nozzle count contributes to print quality, but Mimaki went further.

The JV5’s printheads will print three different dot sizes — large, medium and small. This allows smoother gradations as well as more print detail. The combination can produce high-quality prints at significantly improved speeds.

Print speed and quality modes

By now, you’re probably itching to know how fast the printers will go. Hold your horses! We want to discuss print-quality modes first.

Six printing modes (12 if you factor in uni-directional vs. bi-directional) aren’t particularly unusual, because many printers offer multiple printing modes, although, due to poor print quality, many modes aren’t really usable. With the JV5 series, even the lowest modes produce accept¬able print quality.

The lowest mode, 720 x 540 dpi, offers a fairly decent resolution. Next come the 540 x 720- and the 540 x 900-dpi modes. The “normal” printing mode is 540 x 1,080 dpi, high enough resolution to produce photorealistic images. Rounding out the high-quality modes, you may select 720 x 1,440 dpi and finally 1,440 x 1,440, the super-quality mode. We were absolutely amazed by the images coming off the JV5 (Fig. 3).

What speeds can you expect? Here, the engineering pays off. In the 720 x 540-dpi, bi-directional, four-color mode, you’ll produce approximately 580 sq. ft./hr. You’ll probably want to use the 540 x 1,080-dpi mode because it offers near photo quality.

In four-color, bi-directional mode, you’ll get 430 sq. ft./hr. That relates to 9 sq. ft. in 90 seconds. Even in the highest-quality mode (1,040 x 1,040 dpi, 6 or 8 colors, uni-directional), the JV5 prints a respectable 226 sq. ft./hr.

Easy operation

Okay, Mimaki has attained its speed/quality goals, but what about the ink and media? If you have to “hand¬hold” a printer, you lose that speed advantage. To avoid this, numerous features minimize operator intervention.

We want to start with the ink system. An array of 16, 440ml ink cartridges sits atop the printer (Fig. 4). You can operate the system in a 4-color mode that comprises four cartridges of each color (CMYK) or a six-color combination (CMYKlmlc, for example) that sources two cartridges per color.

Do the math. With 440ml cartridges, if you select the four-color mode, you’ll have 1.76 liters of ink per color. That will produce signifi¬cant printed area without operator intervention.

Even if a cartridge runs out, you can swap an ink on the fly. To maintain quality, a laser scans the printhead during printing to detect clogged nozzles. A cleaning cartridge cleans things up.

As we mentioned, the printer can handle a large media roll, and several accompanying features ensure positive loading and feeding. For example, the JV5 handles media thicknesses up to 1mm and will sense, and automati¬cally adjust, the head height when the media is changed. On some printers, you have to adjust the head height manually.

Also, its power take-up system works in conjunction with its “intelligent” heater system. Heavy media has a tendency to feed inconsistently (it jumps, then lags), and this can cause banding lines across the print. The JV5’s media-compensation system ensures that media weight doesn’t affect media feeding, thus you get improved image quality with less media fidgeting.

Ink options

We’ll wrap up this review by looking at available ink options. In most cases, a given printer uses a single ink type. If you’re interested in an eco-friendly environment, you’ll choose a printer and ink that meets this need. More aggressive solvents will produce more durable images and print on a wider range of substrates, but you’ll need a valid ventilation system and, again, a specific printer for that ink type.

Mimaki actually offers two inks – a solvent and an eco-friendly solution — for its JV5 printers. Its ES-3 inks provide an eco-friendly, wide-color-gamut formula for use in normal (room-ventilated) office environments. The images are durable and UV/outdoor ready.

However, if you need improved scratch resistance and use a lot of heavy media, such as banner mate¬rial, you’ll want to choose the HS (solvent-based) inks. These require machine-installed ventilation. Mimaki offers one that can be added to the printer.

Conclusion

Innovation is Mimaki’s hallmark. The company wanted to, and did, build a high-speed/high-quality printer. With a list price of $37,995 for the JV5-130 or $39,995 for the JV5-160, the pricing is in line with many industrial-quality, solvent-ink printers. The JV5 printers produce super quality at fast speeds with minimal operator intervention. If you’re looking to up the produc¬tivity in your shop, check out Mimaki’s JV5 printers.

Mimaki USA

140 Satellite Blvd., NE, Ste. 0

Suwanee, GA 30024

(678) 730-0170

(678) 730-0188

Company Background: Incorporated in 1999, Mimaki USA Inc. is the U.S. subsidiary of Miamki Engineering Co. Ltd. (Nagano, Japan). Mimaki manufactures wide-format printers and cutting machines.

Contact: Steve Urmano, steve@mimakiusa.com

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery2 days ago

Photo Gallery2 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times3 days ago

Ask Signs of the Times3 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks6 days ago

Benchmarks6 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoWhy We Still Need the Women in Signs Award

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Megan Bradley

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More