Vehicles + Vinyl

Moving Pictures

A gallery of vehicle graphics

Published

18 years agoon

When someone s barrelling down the highway or cruising a high-traffic thoroughfare during drive time, the impact of a memorable (in a positive or negative sense) vehicle graphic can t be denied. Thanks to several governmental and industry groups, vehicle graphics benefits have been quantified, which helps digital service providers and printer-equipped signshops promote their services to would-be clients.

Further, several vehicle-wrap providers, material manufacturers and industry experts have specified what components constitute eye-grabbing vehicle graphics, and what optimizes their lifespans, and have provided ample “money shots” of finished products.

The numbers

According to Stephen Freitas, chief marketing officer for the Washington, D.C.-based Outdoor Advertising Assn. of America (OAAA), truckside advertising and vehicle wraps are a subset of the transit-advertising category, which tallied approximately $1.05 billion, or 19%, of the overall outdoor-advertising market.

“Wrapped vehicles not only place messages in front of target consumers, they also provide the opportunity for direct customer contact through…promotional tactics,” he explained. “It s an innovative medium that can attract hard-to-reach customer targets.”

Combining global positioning satellite (GPS) tracking data and Federal Highway Administration (FHA) traffic-density information, the Traffic Audit Bureau for Media Measurement (TAB) has compiled statistical data for the 50 most populous metropolitan statistical areas (MSAs): population density, median drive times and the number of vehicles required to penetrate a certain percentage of a particular market.

AdvertisementFor instance, Cincinnati, the 27th-largest MSA, maintains an adult population of approximately 1,250,000, and an average daily commute time of 24 minutes. As such, the TAB calculates that a wrapped vehicle would reach 31,783 people if driven from 9 a.m. to 5 p.m.

In New York, a more densely populated MSA with more than 5.6 million 18-and-over residents, a single, wrapped vehicle would reach approximately 58,000 Big Apple residents.

Sam Kaplan, vice president of sales and marketing for Mobile Ad Group (New York City) and a member of the OAAA s marketing committee, began his 30-year career as a graphics designer and served as an instructor at New York City s Parsons School of Design. He joined Mobile Ad Group, whose Mobile Graphics business unit fabricates hundreds of vehicle wraps annually, five years ago. He contrasts the non-existence of vinyl vehicle graphics when he entered the sign industry versus their prevalence today.

“Printed graphics have became inexpensive; vinyls have improved greatly, and so many people have the computer skills to produce them,” Kaplan said. “But it s not just the technology. A lot of young talent has made this a young person s game; most car wraps have a Generation X or Y feel.”

Strategically, vehicle graphics place small businesses on par with large corporations. For $3,000 to $4,000, a business can advertise its name, website, phone number and any other desired information. Kaplan noted that a wrap generates tens of thousands of daily impressions, which reduces the per-impression cost for a month-long campaign to a fraction of a penny — exponentially lower for a longer-term campaign.

“No other medium — TV, print, billboards, radio — can even begin to approach such a low cost per viewing,” Kaplan explained. “This gives businesses of all sizes a fair shot at the buying public s attention. Vehicle graphics provide instant credibility and brand recognition, and these wraps can last up to five years.”

AdvertisementAs a long-term example, Kaplan cited Clive Christian, an upscale, custom-furniture vendor.

“They buy full-page, color, Sunday ads in The New York Times, which are very expensive but gone in a week,” Kaplan said. “With vehicle graphics, the van is parked in a driveway while making a delivery in an upscale neighborhood, and that message continues to reach likely customers.”

To enter this business, Kaplan advised one word — micromanagement.

“When personal computers first became routine office equipment, claims were made that a company could fire its entire creative staff and let the receptionist put together an ad campaign,” he said. “That was a totally untrue statement. There are those who think technology can take care of itself. In this business, that results in some badly pixilated wraps that look terrible. The only way to ensure a quality result is to tightly control procedures from design to installation.”

Equipment choices

Yet, market knowledge and a well-organized promotional campaign mean zilch if a shop or service provider uses inferior equipment or poor preparation techniques. Under these circumstances, a vehicle disparages a customer s image. Formulation upgrades have yielded more conformable, thinner and adhesive films and laminates.

AdvertisementIn her seven years with the company, Molly Waters, a technical account executive with Avery Dennison Graphics & Reflective Products Div. (Painesville, OH), has seen printing technology progress from electrostatic — more known for prolific runs than crisp resolution — to printing with solvent-based inks.Avery Dennison Graphics Division

Be aware that, when preparing a vehicle for a wrap, all paint jobs aren t created equal, Waters advised.

“It s preferable that a car still has an OEM finish,” she explained. “If it s custom work, it s possible that the paint will come off with the vinyl when the graphics are removed. It s also important to make sure it s washed the day before to remove dirt, then wiped down with a wet rag and isopropyl alcohol.”

Avery s primary products for this market are its MPI 1005 EZ fleet-marking film — an opaque film that features the company s Easy Apply? technology, which contains air-egress channels that minimize air-bubble formation — and DOL 1000 pressure-sensitive, glossy overlaminate.

“Matte finishes are available, but they don t provide the same appearance,” Waters said. “A glossy finish provides a finish that more resembles paint, and looks more natural on the car.”

Presently, UV-cured inks are too inflexible for use on a repositionable substrate, but it s only a matter of time before UV inks gain the dexterity for vehicle graphics.

Bruce Nater, product-marketing manager for Océ USA (Chicago), said the Arizona 180 is the company s most commonly used printer for fleet-graphic applications, though the Arizona 90 is suitable for smaller jobs. The company partners its equipment with 3M? products, including 3700 and 6700 solvent-based inks and Scotchcal? RG 3630 film. Nater noted that, although calendered vinyl is adequate for jobs that don t have conformability challenges, cast film is required for extreme stretching and bending.Océ North America Inc.

However, Nater said that, although the dpi should be considered for each job, service providers tend to output wraps at a higher resolution than necessary.

“It s important to bear in mind that these wraps are usually going to be in motion,” Nater explained. “They don t need to be output at the same print quality as POP graphics. It s usually not worth the longer printing time.”

According to Nater, the most significant cost-benefit development has been solvent-based inks that jet through an inkjet printhead at a reasonable cost.

These pages capture the synergy of knowledge, drive, flair and passion when run through an inkjet printer and laminated to the side of a truck, car, van or anything else on two or four wheels.

Enjoy.

Gallery of Vehicle Graphics

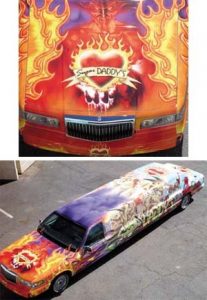

Burn Baby Burn

Did the devil make them do it? Blue Media Productions (Tempe, AZ), a 10-year-old company initially founded to produce golf-tournament paraphernalia, wrapped this limo for Sugar Daddy s, a Phoenix blues club that Andy Salcido, the company s corporate sales rep, described as a “cross between hell and the Sistine Chapel.”

Chris Keal, a Blue Media graphic designer, rendered the vines, roses and flames using Adobe Photoshop.? Blue Media output the wrap using 3M Series 6800 inks, its Arizona 180 printer — with an Onyx Graphics Inc. RIP — and 3M RG 180 Controltac? film with Scotchcal laminate.Onyx Graphics Corp.

Sugar Daddy s has implemented the flaming heart emblazoned upon the hood into its signage and advertising. Contravision North America (Atlanta) provided the window film and conducted a vehicle-wrap competition that bestowed a first-place award for the limo s graphics.

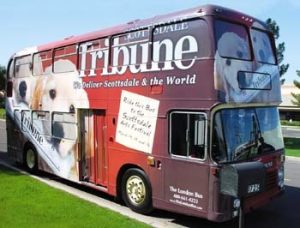

Given that the original London Bridge now resides in the Grand Canyon State, it s only natural that management of the Scottsdale Tribune, which serves Phoenix s most affluent suburb, would opt for a British-style, double-decker bus. According to Salcido, the project s challenges included not having a template and a bus transitioned from England s cold, damp climate to Arizona s dry heat. Blue Media used 1,300 sq. ft. of Controltac media, including 500 sq. ft. of 3M 8171 perforated window film output on the Arizona 180 printer.

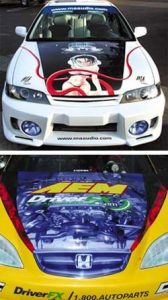

Left Coast Radical

Modern Image (Hungtington Beach, CA) has created graphics for such celebrities as The Fast & The Furious Paul Walker, whose Nissan Skyline he bedecked. Robert Wilson, Modern Image s owner, has run his shop for 13 years.

Wilson came up with this scintillating graphic for MA Audio, which offers premium car speakers, amplifiers and other accessories that help motorheads create eardrum-splitting, custom sound systems. Wilson s shop output the graphics using Roland DGA Corporation s (Irvine, CA) cast vinyl and SolJet Pro II EX solvent-based printer. Modern Image created this high-toned job for AEM/Driver FX s — which sells custom, after-market auto accessories — racing team. He printed the graphics on a Roland SolJet.Roland DGA Corporation

The Butterfly Principle

In Song of Myself, Walt Whitman wrote about butterflies: “You will hardly know who I am or what I mean/But I shall be good health to you nevertheless/…Failing to fetch me at first keep encouraged/Missing me one place search for another/I stop somewhere, waiting for you.”

In that vein, DH Signs of the Times Enterprises Inc. (Victoria, British Columbia, Canada) created this Beetle s graphics for the Vancouver Island Arts and Cultural Highway Foundation to celebrate Vancouver Island s artistic community.

The program comprises a unique media mixture. The company output the flat butterflies and text panels using 3M Industrial Adhesives & Tapes Div. ControlTac? film printed on a Roland SolventJet. For the dimensional butterflies, the shop constructed bodies using Sign*Foam high-density urethane and aluminum wings routed on a Gerber Scientific Products Sabre. Furthermore, the shop painted the body with 1Shot? lettering enamel and installed heavy-duty magnets on the undersides of the butterflies, which lets them be situated anywhere on its body.3M Industrial Adhesives & Tapes Div., Gerber Scientific Products

From Stocks to (Substrate) Bonds

Chris Dyson, who s owned Ads on Wheels (Manchester, NH) for six years, circuitously arrived in the vehicle-graphics industry. A former stockbrocker, he noticed the lack of promotional graphics on most tractor-trailers, trucks and commercial vehicles he encountered.

A Geico Insurance agent realized the value of his company s mascot, the ubiquitous, computer-generated gecko from the company s TV campaign, and contacted Dyson. After having received the image files from the client, Rob Fitzpatrick crafted the design using Adobe Illustrator 9. Ads on Wheels output the wrap with its EFI UltraVu? 2360 printing at 360 dpi. Ads on Wheels typically employs Avery Graphics 1005 2-mil, Easy Apply vinyl with its DOL 1000 glossy, liquid laminate; the company also uses 3M 8620 and 180C cast material.Vutek Inc.

Dyson advised not laminating window film, because it shrinks and peels more quickly.

From Pfeil s Files

Pfeil Design (Innkreis, Austria) comprises a full-service, vehicle-graphics shop. Owner Marcus Pfeil and his staff still engage in traditional airbrushing and pinstriping, yet they ve embraced solvent-based, inkjet-printer and plotter-vinyl applications.

Pfeil s reputation has spread across Europe; clients from Russia, Germany and Britain seek his service. He handpaints and airbrushes using Standox and House of Kolor paints and Sata, Iwata and Devilbis brushes.

Pfeil was given a rare gift for this job. The client, who owns a petroleum-refining company, gave him complete artistic freedom to decorate his trucks, and instructed him that money was no object. To that end, he combined airbrushed effects with MACtac (Stow, OH) 9800 cast vinyl and Permacolor? pressure-sensitive overlaminate.MACtac

When Decals Fail

My shop, Straightline Graphics (Huntington Beach, CA), specializes in vehicle-graphic installations. I ve learned how to manage registration, window-molding, door-handle and hinge problems. Over the last 25 years, I ve gradually improved my speed and skill.

I use high-performance, cast films because they perform well and offer the strongest warranties. Their ensured long-term graphic success outweighs the added material expense.

In 1999, however, I began experiencing mysterious problems with many Chevy van installations. Normal lifting commonly occurs around wheel flares. This was different; the outline window panels, and the ridges that accompany sliding-door tracks, wouldn t let vinyl stick. When my bank account began suffering as much as my ego, I took action.

Trouble brews

Five years ago, Chevy introduced the 3500 Series van, which was designed for industrial and delivery work. It featured soft bumpers, flared wheel wells and some channelled or beveled sections in lieu of windows. That same year, one of my biggest accounts, an energy-drink company, selected a fleet of Chevy vans for its cut-vinyl graphics. Prior to that decision, I d installed more than 300 graphic kits on older-model Dodge vans.

I d purchased my cast film from whatever supplier offered the unusual shade of imitation gold and raspberry necessary for the design. However, I sensed trouble after the first delivery of unmarked Chevy vans, which featured depressed, side-window panels surrounded by a V-shaped channel that measured approximately 1 in. deep and 1 in. wide at the top.

I used my heat gun and wet fingertips to lay down the vinyl. The installs took a bit longer than before, but they looked good. At the end of the week, I dispatched six newly dressed vans.

That year, I completed approximately 300 Chevy kits; I applied many myself and also sent pre-cut, masked kits across the United States and Canada for other installers. By mid-year, I d taken a few warranty calls regarding popping vinyl. However, the scope of the problems would become much larger in coming months.

To the rescue

As the summer months passed, my shop seemed to be cutting as many repair kits as originals. I called my vinyl distributor, Southland Sign Supply, and then the manufacturers themselves.

The manufacturers responses weren t satisfactory. One said it might be an installation problem, or merely a faulty batch — in essence, “Don t worry; be happy; buy more.” The other, who wasn t sure it was a film issue, asked to see how I handled their product. Maybe, they thought, I was doing something wrong.

The local service reps inspected warranty claims, checked my technique and offered advice during an installation. We decided they didn t know any more than me. The reps also pointed out that their conventional cast vinyl wasn t the best product for corrugations; they suggested I use fleet-grade film.

That was easier said than done. Raspberry and imitation gold were available for only standard cast vinyl, and I needed readily available stock. Fortunately, I found a manufacturer that delivered a few rolls of material. In return, my shop became a beta-testing site for a new vinyl formula for these stretched-decal applications.

During the service visit, I learned that vinyl bonds more readily to a vehicle surface than to vinyl itself. Vinyl s plasticizers make adhesion difficult. This helped me understand why most vinyl failures occurred in the overlaid sections of graphics passing over a “V” channel, especially in the corners where it s hardest to apply pressure.

We added maximum heat and pressure to the channels while anticipating claims on the horizon. I still thought I needed to hedge my bets in case the new formula didn t offer improvement.

That December, I attended final design meetings with project scientists at the manufacturer s nearby lab. After a review of test data, we agreed the new formula offered strong formability and adherence.

Satisfied, we took delivery of several 48-in. rolls of the new film. We tested the first batch on a dozen vans, and it performed well through cutting, weeding and installation. Most important to us, it proved stable in those pesky channels.

We shipped kits to Duluth and Boston — places where snow shovels outnumber palm trees by a wide margin — during wintertime. The combination of low temperatures and a low-tack, fleet-film-type adhesive made it reposition too well; it wouldn t stick. The manufacturer made changes and eventually developed film with the same adhesive tack as standard, 2-mil cast film with the stability of fleet-grade film.

When I installed the new vinyl, I immediately felt a difference in film conformability, bond strength and heat reaction. By this time, I d devised tests for tricky van applications and performed quality checks on each new batch. All tests showed great improvement over the old formulation.

Back on top

After that rough year, I rebounded with this major project and produced many smaller ones using the new material. The ratio of successful jobs to repairs tipped in my favor. The Straightline “ship” stabilized as complaints slowed to a trickle, then stopped altogether.

We used Arlon s (Santa Ana, CA) Calon? EF film; “EF” means “extra formable.” The material was only available in raspberry and imitation gold for more than three years while Arlon completed durability and processing tests.Arlon

This year, Arlon offers Calon EF in all available cast colors. I ve now used the new film for single- and double-layer cut decals. Also, I m using white EF film for airbrushing and inkjet-printing work. The Chevy van was followed by various vehicles, ranging from PT Cruisers to the new VW Beetle, with bumps, curves and other installation challenges.

The lesson I learned was: Beware of small changes in large quantity. You can sink as easily under too much sand as under a boulder. Further, keep communication open with suppliers who are willing to work with you.

After Southland put me in contact with the manufacturers, I simply needed to find a company interested in product improvement and customer satisfaction. At least one of my suppliers had an idea file ready for testing.

Problems present opportunities. A new ink or airbrush paint may cause application tape not to stick. Or, an upgrade in cutting or printing machines may cause a problem with your current release liner. In my case, Arlon attacked a formulation imbalance, which put me ahead of my competition. The manufacturer benefited by devising a new product, while my graphics gibed with the new Chevy van. Above all, I generated new revenue, rather than repairing decal failures.

–John Checkal,

Straightline Graphics

Flights of Fancy

Picture yourself in the cockpit, cruising at 10,000 ft., the world beneath your feet and an azure horizon beyond. Thanks to the work of Carmen Rentzios, the owner of the Greenwood Village, CO-based FastSigns franchise, visitors to neighboring Engelwood s Centennial Airport can see the truck s depiction of Adam Air s million-dollar project, which entails an innovative design featuring front and rear engines.

The graphics comprise Rexam (now South Hadley, MA-based IntelliCoat Media Technologies) DMC3VLA 3-mil, cast vinyl output on a HP 3500 CP inkjet, protected by SUN 3.2 lustre-finished, UV laminate. The graphics required 14 man-hours to install. Further, the shop fabricated graphics for the jet portrayed on the truck.

Post Time

Sealand Graphics (Div. of Sealand Power Industries Inc.) (Bennington, VT) didn t have to leap tall buildings in a single bound to decorate this bus. They merely applied 3M s 8620C 2-mil, high-performance vinyl, which features the company s Comply? air-egress system that minimizes trapped-air bubbles. The Man from Krypton is protected by 3M 8910 high-gloss overlaminate.Post Graphics Inc.

Miratec Systems Inc. Goes Big-ScreenMiratec Systems Inc.

Signmakers and movie moguls know their crafts true art is creating the perception of reality. Through careful management of color, light and viewing perspective, the creator can draw attention to, and significantly enhance, a story.

A recent Miratec Systems (St. Paul, MN) project required combining the skill of vinyl application with silver-screen artistry to uniquely recreate an American aviation icon. This December, Warner Brothers is slated to release The Aviator, a feature film directed by Martin Scorcese. The movie stars Leonardo DiCaprio as billionaire aviator Howard Hughes.

The movie s creative team needed a replica Sikorsky S-38 flying boat aircraft, which Hughes had owned. The plane s key scene in The Aviator depicts Hughes flying over a movie set to impress Katherine Hepburn, portrayed by Cate Blanchette, when the two legends worked together on an early-1930s film.

The Sikorsky S-38 prior to decoration. Miratec s President Bert Guinee decided to decorate the plane with 2-mil translucent and 4-mil opaque vinyl coupled with a short-term adhesive.

History

Starting in 1928, approximately 100 S-38s were built, but none remain today. In the United States, however, two S-38 flying reproductions were built between 1995 and 2002. Construction utilized original Sikor-sky engineering drawings, original components salvaged from around the world, and new materials with custom-fabricated assemblies.

A reproduction aircraft owner offered the plane for the movie, but Warner Brothers design staff didn t want its handpainted, zebra-stripe pattern. The paint job replicated an original S-38 that Martin and Osa Johnson, a Kansas couple, owned. In the early 1930s, the Johnsons used their aircraft to film a series of pioneering documentaries of African tribal communities and wildlife.

Well-known authors, naturalists, and explorers, the Johnson s S-38, named “Osa s Ark,” was designed with zebra stripes to ease the impact on the natives, who would be seeing their first aircraft. Although a fitting tribute to the Johnsons and their work, the Sikorsky was a far cry from the sedate gray that had graced Howard Hughes S-38.

Getting to work

At an impasse — removing and repainting the zebra stripes wasn t viable — the plane s owners asked Miratec Systems president, Bert Guinee, for possible temporary solutions. They were familiar with Miratec Systems vehicle-wrap projects.

Specifically, they needed to cover the stripes on the aircraft s fuselage and wing pontoons for the three-to-four-week filming of the S-38 s movie scenes. In addition, the application had to withstand extended salt-water submersion and long flight periods at speeds approaching 100 mph. And, of course, the process had to be reversible without damaging the paint underneath.

Following a meeting with the S-38 s owners, Miratec Systems inspected the aircraft to determine the best materials and application process. A giant compared to its contemporaries, the S-38 is 40 ft. long, with a wingspan exceeded 70 feet.

Given the S-38 s amphibious capabilities, it resembles a boat more than an aircraft, which had to be considered when evaluating wrapping the plane in vinyl. Any such design details needed to replicate the visible details on Hughes S-38.

The S-38 s lower fuselage comprises a wooden frame with an aluminum panel skin. The fuselage top, which would remain unchanged, is upholstered in black leather. The pontoons are aluminum; a varnished-cotton fabric covering, typical for that era, adorns the wooden wings.

Installers carefully used squeegees of various sizes and air-release tools to remove bubbles.

Bringing it to life

Miratec developed a laminated, vinyl construction that comprised 2-mil translucent and 4-mil opaque film with a short-term adhesive. This system provided the right combination of adhesion with ease of removability. The installation coincided with a routine maintenance check in Minnesota, where the plane was built. After the three-day installation, the plane left for on-location filming in Nevada and California.

The transformation commenced with a thorough surface cleaning. Like land vehicles, aircraft collect mashed bugs, and, at 100 mph, the situation is compounded. Cleaning with a soap-and-water compound was followed by a solvent wash using a water/alcohol mixture. Final preparation required thorough drying of the cleaned surfaces using lint-free towels.

Film application began along the rear fuselage sides and proceeded forward, with emphasis on preserving the characteristic skin panel, and the hull and pontoons rivet lines. The job required sharp definition around the flight-deck windows, areas particularly visible during close-up filming.

Carefully applied heat helped stretch the film over rivet heads. Vigorous use of a rivet brush ensured sharp definition and firm film contact. Where a vinyl-film edge would be exposed, Miratec Systems applied liquid primer to enhance adhesion and reduce the chance of lifting. Installers used several sizes of hand squeegees to set the film and remove air bubbles. An air-release tool removed trapped air bubbles.

Final application focused on the aircraft s compound curves on its nose and flotation pontoons. Primer, heat, vinyl stretching and exact trimming drew the film over the curves without visible creases or substrate exposure due to post-application film shrinkage.

Although the plane s nose was accessible, the pontoons could only be reached by working under the plane s lower wings. Maneuvering required dexterity when juggling vinyl film sheets, a heat gun, squeegees and a rivet brush.

The installation, which required approximately 35 man-hours to complete. progressed smoothly under the watchful eye of the aircraft s mechanic, who had also painted the zebra stripes. Resplendent in gray, though certainly a bit less flashy than before, the S-38 departed on schedule for the two-day, 1,100-mile flight to the movie set and, presumably, cinematic fame.

If you re a moviegoer, see The Aviator and keep an eye out for the gray and black plane with the wing pontoons and boat-like shape. And, remember: What s in the movies isn t always what it seems.

— Tim Haskins

New Ad-ition

Even purveyors of the written word know the value of fleet-graphic advertising. Ad Graphics (Pompano Beach, FL) created this wrap to promote The Miami Herald s Spanish-language edition. The H1 Hummer s graphics comprise 8620 film with 8910 laminate that were output on a Scotchprint? 2000 system.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

INX Promotes Three to Vice President

6 Sports Venue Signs Deserving a Standing Ovation

Hiring Practices and Roles for Women in Sign Companies

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet3 days ago

Tip Sheet3 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management2 weeks ago

Business Management2 weeks agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Editor's Note1 week ago

Editor's Note1 week agoWhy We Still Need the Women in Signs Award

-

Benchmarks15 hours ago

Benchmarks15 hours ago6 Sports Venue Signs Deserving a Standing Ovation

-

Line Time2 weeks ago

Line Time2 weeks agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines