Let's face it, digital printing is showing up just about everywhere. Small shops are jumping on board with low-cost printers. Grand-format printers are becoming affordable to even mid-sized shops. A holdout has always been the manufacturing/routing side of the business.

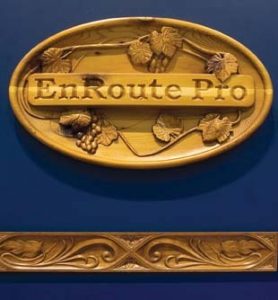

You know these guys. They can create wood signs that appear to take weeks to carve. They can crank out unique sign shapes all day long without breaking a sweat. Sure, you can consider CNC routing a digital function, but the types of files you feed these monsters are typically vector or line based.

So, does such a shop need a wide-format digital printer? The shop could offer a wide range of products, but, until recently, CNC operators would rarely see a digital print in their area. A new development is changing all of that. The industry, in essence, is giving the CNC router eyes.

MultiCam and its products

MultiCam Inc.'s routers are robust, fast and affordable, ranging from the entry-level 1000 series all the way up to the giant MT Pro series. They also offer a line of waterjets, plasma cutters, knife cutters and lasers.

Before we begin discussing the MultiVision option, let's take a closer look at some of the MultiCam products. We'll concentrate on the 3000 series, as this is probably a fairly standard configuration.

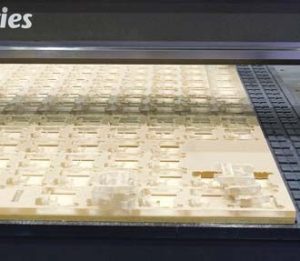

MultiCam's devices are solidly built with heavy tables. An optional vacuum hold-down system ensures the media (Fig. 1) is held firmly in place. Talk about power, the 3000 series (Fig. 2) can handle either a 5.5- up to a 10-HP spindle. With a rapid traverse speed up to 1,700 in./sec., the 3000 will make fast work of a sheet of material. Choose a 50 x 50-in. table size if you're working mainly with half sheets, or select an 80 x 145-in. table if you work with full sheets.

Advertisement

All MultiCam routers come with an easy-to-use control system, a handheld device that interfaces directly to the router. The controller (Fig. 3) offers various controls at the operator's fingertips. It boasts a 1000-line buffer that accepts both HPGL and G-Code commands. It also interfaces via a TCP/IP interface to the DNC (PC-operational) software. The software includes a job-preview function, a job-history function and a job-reporter function that can be used for shop planning.

The routers offer a wide variety of options. You can add automatic tool changers, engraving heads, dust-collection systems and much more. Some very interesting productivity tools, such as the template-digitizing system and the bar-code reader, let you scan designs and save job settings that can be recalled at the wave of a wand.

The 2000 series laser cutter also caught our eye. This device can precisely cut and even raster engrave a wide variety of materials (Fig. 4). The system comes with an integrated materials database and the same controller system as found in the CNC routers.

Let's now specifically look at the new MultiVision option.

What's the big deal?

We all know about printing posters and full-color vehicle graphics on digital printers. An exciting market for digital printing is point of purchase. If that term is unfamiliar, you can easily see what we're talking about in your local supermarket or mall. Little signs at the cash register, or even in the aisles, push one product or another. In many cases, the display mimics the product shape, or it may be a full-size cutout of a celebrity spokesperson.

Advertisement

Many of these displays are produced on materials like foamboards, which can be very easily and precisely cut with a router. Get the connection? Print the graphic on adhesive vinyl, contour cut the foamboard, trim the vinyl to fit on the foamboard and apply. That's great if you're only contending with a couple pieces. What if you have 100, or even 1,000? This would be very time consuming and probably not cost effective.

How do you get the vector-cut lines to line up with the printed image? It seems simple. Create the artwork in a paint or drawing package, and use a special color to outline the image.

The problem starts when you load the media. How do you register the sheet, and how do you compensate for media drift? Years later, we actually have some good solutions for vinyl graphics, but what about rigid materials?

CNC registration issues

The routed media is typically rigid and must be positioned on a table. Seemingly easier to manage than flexible-media sheet, such as adhesive vinyl, rigid materials introduce a different issue. Specifically, you must ensure the media is placed in exactly the same position every time a sheet is cut.

While CNC routers can be extremely accurate (for example the MultiCam routers are repeatable +/- 0.001 in.), the stock may vary from sheet to sheet. In addition, the operator may skew the media slightly during loading. Across the length of a 4 x 8-ft. board, a tiny registration mistake will be amplified enough to ruin a significant number of pieces. Performing trial-and-error placement will further slow down the entire process.

MultiVision to the rescue

Advertisement

MultiCam recognized the market potential and introduced MultiVision, a combination of hardware and software that can visually recognize media registration marks and then automatically compensate for skew and image drift.

During artwork creation, the object's outline is made as usual. In addition, the designer will include three registration points (Fig. 5) around the image.

The piece is printed on the digital printer. MultiVision will look for the registration dots printed on the media and then transform the outline to precisely cut the object out of the media. Multivision is installed in the tool bay next to the spindle, and it can be added to any of their routers. The option costs $9,000.

Quality

Take a look at the output quality (Fig. 6). Whether cutting out dimensional letters, cool pop-outs or fine 3-D architectural elements, the results are spectacular. Each cutting/routing technology has its place, and MultiCam offers them all.

MultiCam recognizes that digital printing is now entrenched in the sign industry. The new UV printers that print directly onto rigid materials opened up a big opportunity for CNC router owners. Offering a means to accurately contour-cut printed images opens up point-of-purchase and tradeshow-graphics opportunities that weren't easily attainable before. MultiVision is a viable solution and an affordable add-on.

MultiCam

1025 West Royal Lane

DFW Airport, Texas 75261

(972) 929-4070

Fax: (972) 929-4071

www.multicam.com

Contact: Kathryn Estes, marketing

Company Profile:

Since the 1980s, MultiCam has been producing automated positioning systems (CNC cutting solutions). CNC technologies include router, laser, plasma, waterjet and knife cutters.

Tip Sheet4 days ago

Tip Sheet4 days ago

Business Management2 weeks ago

Business Management2 weeks ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Real Deal5 days ago

Real Deal5 days ago

Benchmarks18 hours ago

Benchmarks18 hours ago

Editor's Note1 week ago

Editor's Note1 week ago

Line Time2 weeks ago

Line Time2 weeks ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago