While waiting for a flight home from the International Sign Assn. tradeshow in Orlando, FL, I browsed the contents of a nearby bookstore, which stocked a series of Dummies books, including Computers for Dummies, Gardening for Dummies and more. With their simple, step-by-step instructions for learning various tasks, these books are quite popular. Thus, seeing that people generally favor quick and easy learning curves, this month, I’ll provide a simple approach for readers with little or no neon-sign or lighting experience.

What is neon?

Precisely, neon is a gas. But to signmakers, neon refers to a custom-made, electric lamp that comprises gas-filled tubing. Some electric lamps — those giving different shades of red light — are often filled with neon gas. Thus, "neon signage" is the name given to such signs.

Excluding a few artistic exceptions, electric lamps, which are typically tubular-shaped glass bodies, are also called neon tubes. But why use glass? Glass and artificial lighting have been linked since the Middle Ages, and today, glass serves as the only material physically and economically capable of keeping neon gas pure inside a tube throughout its operational lifetime.

Because glass tubes for making neon are available in different sizes (from 8mm to 25mm diameter), various widths of the operating lamp’s light line can be chosen to accommodate the application.

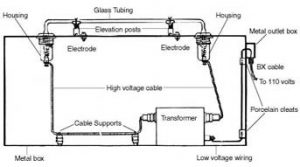

As in every electric lamp, the neon tube must also have two connecting wires to create a closed electrical circuit. The connections (also known as electrodes) between the electrical cables and gas inside the lamp are usually attached at the ends of the neon lamp’s glass tube (Figs. 1a and 1b). Only the shortest path between the neon tube’s electrodes will be lit, so a neon lamp must have no "dead" sidearm. Consequently, a neon lamp must be made from a continuous piece of tubing.

Unlimited shapes

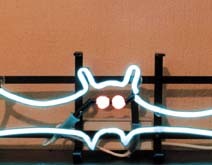

In contrast to off-the-shelf fluorescent lamps — which are mostly straight and only available in a few standardized lengths and diameters — the custom-made neon tube lamp can be shaped according to an application’s constraints. Due to the continuity requirement, rendering complex logos or lettering in neon tubes can result in rather complex glass shapes (Fig. 2). Note that, oftentimes, a neon tube lamp isn’t flat, but rather, three-dimensional.

Tube shapes derived from a sign’s design are given to a glassblower as a blueprint (i.e. glass pattern). Creating shapes from a straight glass tube requires skill and constant training. To shape glass, tubing must be heated to an almost liquid state. For lighting purposes, the maximum tube size is approximately 16 ft. long and 25mm in diameter.

How a neon lamp is used

Because it can be custom made to suit an application, a tubular neon lamp has many uses. Although they pose a few technical limits, neon lamps offer the broadest range of colors (approximately 110 standard colors are available) and a very long lifetime (approximately 30,000 to 80,000 hours).

Similarly, neon generates more light for a given amount of power than incandescnet lamps or LEDs. Only fluorescent lamps surpass neon. Further, unlike incandescent or fluorescent lamps, neon tubes can be switched on and off continually, or dimmed, without affecting the lifetime.

Neon operates somewhat like bottled lightning as there’s no metallic conductor (such as tungsten) between the tube ends, only gas. Just like atmospheric air needs a storm cloud’s high voltage to break through and become conductive (so the lightning bolt can carry the electricity), a neon tube needs high voltage to start and operate.

Neon tubes can’t operate directly from the 120V main line. A special neon transformer, which generates high voltage and limits power to the neon tube, prevents destructive effects. This special transformer (like the electronic type commonly used today) safely starts and operates the lamp.

A neon lamp itself shouldn’t require maintenance during its lifetime. However, if damaged, the glass can be fixed and refilled with pure gas for a new lifetime of 30,000 to 80,000 hours. As every electric sign, a neon application needs periodic maintenance, especially when mounted outdoors. Dirt, dust and debris should be removed, and the electrical parts and connections require at least annual inspection by an authorized and experienced neon-sign electrician.

NEVER attempt to service a high-voltage electrical installation yourself, even if it’s only a small, portable "beer sign".

How a neon lamp is installed

With the previous caveat in mind, a non-neon signmaker might create all structural parts and prepare a display for the required approval by a test institute or electrical inspector.

If all parts aren’t listed by a nationally recognized testing laboratory (e.g. UL, ETL, CSA, etc.), field-installed neon tubing must be field inspected by the local authority having jurisdiction (AHJ), which is usually the electrical inspector in town, prior to operation.

Neon-tube installations will vary due to design and intended use. In one common lamp form installed in front of a surface (Figs. 3a and 3b), all electrical connections are made behind the surface. Special feed-through connectors, also called "housings," provide electrical contact for the tube and electrodes, and protect high voltage wires from accidental exposure to the user (Fig.4).

Finally, another installation technique is to install the electrical connections behind the visible plane of the neon tube; the high-voltage wire is twisted to the electrode leads. Further, a cap/cup of glass or plastic insulation material prevents accidental contact with exposed, high-voltage parts (Fig. 5).

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery2 days ago

Photo Gallery2 days ago

Ask Signs of the Times4 days ago

Ask Signs of the Times4 days ago

Real Deal1 week ago

Real Deal1 week ago

Benchmarks6 days ago

Benchmarks6 days ago

Women in Signs1 week ago

Women in Signs1 week ago

Photo Gallery1 week ago

Photo Gallery1 week ago

Women in Signs1 week ago

Women in Signs1 week ago