Soon after starting in the fleet- graphics business, I made my first big sale — a $26,000 job that involved removing old trailer graphics and applying new markings. In the language of decal installers, the respective processes are called de-identification and re-identification.

I was proud of my sales prowess, walking tall and strutting my stuff. However, I was soon given a reality check, and learned a little about humility and a lot about removals.

I had bitten off more than I could chew — our company didn’t have the manpower to keep up with the work. To keep my customer happy, I actually exchanged my suit for work clothes at the end of the day and helped scrape off old vinyl.

I also learned something that you may have already discovered — removal jobs are never fun, rarely profitable and frequently plagued with problems. While it’s usually best to pass on these jobs, removals are often an unavoidable part of a graphics program.

No bowl of cherries

To date, no one has discovered a secret formula that makes old vinyl immediately disappear from the surface that it covers. Vinyl graphics only peel off without a trace of adhesive residue when they shouldn’t. Planned vinyl removals usually require long, frustrating hours of hard work.

Several citrus-based adhesive removers have been developed that considerably reduce the potential hazards to the environment, substrate and product user. Two such removers are Orange Peel, marketed by Graphic Adhesives Products (Burbank, CA), and Rapid Remover from Rapid Tac Inc. (Merlin, OR).

New plastic blades allow signmakers to scrape old vinyl adhesives without gouging, cutting or scratching the substrate. And power-drill vinyl erasers quickly abrade both facestock and adhesive.

No product, however, replaces the old-fashioned elbow grease required for almost all removals. Several factors make this chore hard work. As vinyl gets older, the leaching plasticizer tends to make the film brittle. Picking off little bits and pieces of film is aggravating and time-consuming. During de-identification, the adhesive can also delaminate from the facestock.

To minimize the tedium, signmakers and decal installers have developed various graphics-removal procedures. Most employ a combination of heat, chemicals and tools.

Traditional removal procedures

The most common, reliable method of vinyl removal is to apply heat and then peel the film from the surface. The heating process softens the vinyl facestock and the adhesive. A propane torch or industrial heat gun provides sufficient heat to remove smaller areas containing letters and graphics.

Larger areas, however, need to be heated. A huge propane torch — known as a weed burner — is a perfect heat source for these jobs. With an extra long hose, the propane tank can be left on the ground, safely leaving the scaffolding free of clutter.

Heat a large section of the truck surface for approximately one minute. Keep the flame moving so as not to burn the vinyl or substrate.

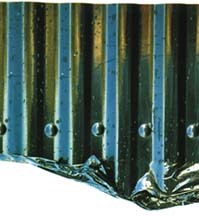

To keep the surface hot when removing graphics, you can also direct heat from a torpedo furnace — also known as a "salamander furnace" — onto the truck’s inside wall. The furnace heat will keep the surface warm much longer, which helps keep the adhesive and vinyl soft and pliable.

After heating, use a fingernail, a Teflon

Tip Sheet3 days ago

Tip Sheet3 days ago

Business Management2 weeks ago

Business Management2 weeks ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Real Deal4 days ago

Real Deal4 days ago

Editor's Note1 week ago

Editor's Note1 week ago

Benchmarks14 hours ago

Benchmarks14 hours ago

Line Time2 weeks ago

Line Time2 weeks ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago