To drive an object electrically, you need to connect it to electrical wires via metallic contacts. A lamp or a luminaire is no exception. An incandescent or a fluorescent bulb illuminates, for example, when it contacts with metal connected to the wires that deliver current, or voltage. You can switch on a flashlight without using wires, but we all know its lamp connects via a metal piece that draws current from an electrical-energy-storing battery.

Have you seen a lamp (or any other electrical device) that’s driven by electricity, sans a physical metal contact to the source?

Sure, the charging system on an electric toothbrush. An electric toothbrush stands on a charger and recharges, but doesn’t have metal contacts that touch the charger. Somehow, however, it connects to the charger and draws the electric charge required for future use. This, of course, is the planned design. Imbedded into a toothbrush casing, exposed-metal charging contacts would corrode fairly quickly, because the toothbrush is frequently exposed to liquids. How does it get charged without a metallic connection to the charger?

The answer is electromagnetic induction, a process that couples magnetic energy to electrical energy (in proximity), while in the presence of changing magnetic and electric fields. English scientist Michael Faraday discovered this phenomenon in 1831, and, later, it was titled “Faraday’s law.” It’s one of the four Maxwell equations – the physics underpinnings of electricity and magnetism. Today, electromagnetic induction is frequently used in various applications, including power generation and transmission.

Transfotec (TFT) Intl., a wholly owned subsidiary of EMD Tech-nologies (Saint-Eustache, PQ, Canada), has found an exciting application for this phenomenon – electromagnetic induction – in the lighting industry. Transfotec’s core strength is transformer technology, and its engineers have applied their knowledge of transformers, and the related field of electromagnetic induction, to create devices for lighting LED strings where the LED modules need not remain in a fixed position.

Advertisement

TFT calls the devices LED Contactless Modules (TFT-LCMs), and they ship with an accompanying master power supply (TFT-LMPS), becoming, TFT says, parts of the TFT LED Contactless System. “Contactless” means no connectors, soldering or crimping. Instead, a standard, 14-AWG, single-stranded wire loops (freely) through a series of LED modules; they make electrical contact via the electromagnetic energy transfer. TFT warranties the system for material and workmanship defects for three to five years (see the warranty for variances).

TFT-LCMs may prove particularly useful in the channel-letter and cabinet-signage illumination because it allows signmakers to position the LED strips to thus generate their desired illumination patterns. Signmakers can construct their own illumination strips by simply sliding the LCMs over the load wire, placing – or moving – them anywhere along it.

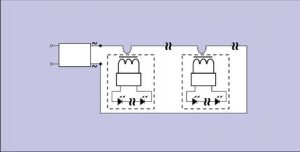

The patent-pending TFT-LCMs operate by employing Faraday’s electromagnetic induction to transfer AC current from a master power supply (Fig. 1) to a 20KHz AC current, via a magnetic coil, that is, a transformer placed inside the LCM. The AC current is converted to DC current via an adaptation transformer, to drive the LED as shown in Fig. 1.

Electromagnetic induction allows the energy from the AC current loop to couple to the magnetic coil inside the LCM and then back to AC current without any physical metal contacts. The 14-AWG stranded wire carries the same AC current to all the loop’s LED modules, regardless of the current, color, quantity or voltage requirements or characteristics of the LEDs.

Two immediate advantages are obvious: The system is virtually connection-free, and you only need two connections to carry the AC current through it. Also, AC current is much less prone to corrosion. The electrical driving of the LEDs is efficient because no ballast resistor or regulator is used, and, additionally, the use of low-power LEDs results in uniform heat distribution, which contrasts with high-power LEDs that may require heat sinks.

Advertisement

Transfotec says it achieves more than 90% electrical-power efficiency by converting the source AC current to the DC that drives the LEDs. Compared to standard LED DC-current or DC-voltage drivers, the Class 2-type, TFT-LMP’s power supply is larger and slightly more expensive. Nevertheless, the overall cost of the TFT’s contactless system is less than most DC-current/voltage driven topologies that require more electrical connections (that may be less energy efficient).

LCM modules

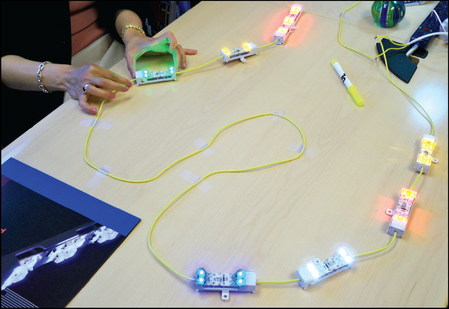

I tested the TFT-LCM’s operation. Electromagnetic induction is no secret to me, but, once I constructed and energized the loop, I was elated when the contact-free LED modules came on. The modules remained bright and uniformly lit as I moved them along the loop wire, and, although I didn’t perform any photometric measurements, the LED colors were quite pleasing. The D65 white LEDs appeared appropriate for channel-letter and cabinet-illumination applications. Further, I observed no flickering during the time the LEDs remained on – a total of approximately one hour.

Practice

I spoke with TFT’s general manager, Éric Giguére, and its principal engineer, Alain Guimont, regarding their LCM product development. Because different manufacturers’ LED performances significantly vary, TFT adopted a screening and evaluation practice. Its engineers perform their own stress and thermal-aging tests at a much-higher temperature (80° C) and drive current (40-70mA) than would be experienced in normal operating conditions. They also determined light-output stability by measuring brightness and color before and after the tests. The selected LEDs show only a 15% drop in brightness during testing, but return to within 90% of their original brightness after one hour of cooling.

Performance

TFT offers white, red, green, blue and amber LEDs, at three brightness levels – Econobrite, Equibrite, and Megabrite LCMs – to match 15, 30 and 60mA neon counterparts, respectively. During normal operating conditions, the efficacy of the different TFT LEDs varies from 58 to 65 lumens/W; luminous intensity varies from 56 (8 LEDs/ft.) to 174 (24 LEDs/ft.) lumens for white LEDs; the wattage per foot consumed ranges from 0.992W to 2.68W. (The optical and electrical power-per-foot performances, i.e., linear density, are given here because these are appropriate for LED strips used in channel letters.)

Although these are decent light output and energy-efficiency characteristics, you can expect much higher performances from industry-technology improvements currently under development for the next-generation LEDs.

Valid lifespan determination remains an issue for LED luminaires in general. It depends on the LEDs’ driving conditions and the channel letters’ or cabinet signs’ interior, ambient temperatures. While most worry about outdoor high temperatures degrading a sign’s interior LEDs, low-temperature extremes (-40° F) may not degrade the lifetime, but could change the light-output characteristics significantly. Although 50,000+ hours are common LED lifetime quotes from manufacturers today, more rigorous testing needs to be done for realistic values.

Advertisement

TFT LED system compared

TFT LED channel letters appear to outperform many others from the industry with respect to two electrical factors: power-supply loading and energy consumption per foot. In the red TFT system, a 75W power supply can load 99 ft. of LEDs (32 LEDs/ft.) while consuming 60W, whereas one of the industry leaders loads 54 ft. (6 LEDs/ft.) with 60W. If the data is correct, 83% more loading would be possible with the TFT red system, meaning that much more electrical energy is utilized towards lighting from an equivalent power supply.

Currently, 90% of Transfotec’s sold LCMs are serving the signage industry, while the remaining applications are in architectural lighting. I expect to see increased uses of TFT LEDs in signage and other such consumer products as garden, cove and holiday lights.

Tip Sheet1 week ago

Tip Sheet1 week ago

Ask Signs of the Times2 days ago

Ask Signs of the Times2 days ago

Real Deal1 week ago

Real Deal1 week ago

Benchmarks4 days ago

Benchmarks4 days ago

Editor's Note2 weeks ago

Editor's Note2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago

Photo Gallery6 days ago

Photo Gallery6 days ago

Product Buying + Technology2 weeks ago

Product Buying + Technology2 weeks ago