DO WE REALLY need to explain what a raster image processor (RIP) does? In a nutshell it takes your artwork and image files, and converts them into a format your printer can use to produce printed output. In this day and age the printer’s internal workings are basically irrelevant. If you use any type of digital printer, be it eco-solvent, UV or latex, you no doubt use some type of a RIP. End of story, right? Not necessarily. You may not know that RIPs can offer a lot of time- and money-saving features. Maybe you need to upgrade your existing RIP or purchase a new one to get all of the benefits, but you may find that what you get is well worth the money.

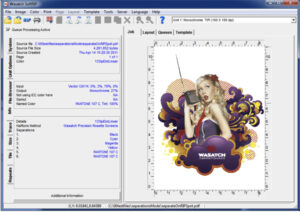

Many features have been around for several years. We tend to think in terms of scaling, step and repeat, and color correcting, but many RIPs offer features like nesting: You can combine a number of prints on the same page in order to save media. This is imperative when working with decal sheets or UV-printed images that need to be digitally finished. A new trend we are seeing is that some RIP manufacturers are using AI in the nesting module to get the best use of media possible.

Within many RIPs you will also find the capabilities to create and modify ICC profiles. While this may be an add-on option and will require a colorimeter or spectrophotometer, it can greatly improve color accuracy and consistency within your workflow. In addition, you can adjust ink levels so that you are only using the right amount to produce colors, thus reducing ink costs and helping to eliminate bleeding and blooming with difficult media.

Some RIPs offer features very specific to signshops. They can generate grommet placement on banners so that you know where to fold the media and where to add the grommets. There are also aids for creating the proper media overlaps for billboards.

Cutting is a very common function in signshops. We’ve already mentioned decal sheets and finishing UV prints. In order to get complex outlines cut, the designer or operator typically draws the contour-cut paths around the images. The RIP would first print the image, which would then be loaded into a vinyl cutter or finishing machine, then send the vector files to the cutting device to finish the job. It could get very complicated and mistakes could happen. Many RIPs now allow the operator to generate contour lines in the RIP software, thus eliminating that step from the designer. In addition, the cut paths can be previewed prior to releasing the job to process.

In this vein, some high-end RIPs also support preflight to soft proof for color accuracy. All of this can be tied together for end-to-end job management that also incorporates job-automation tools. When properly set up and configured, your shop can be run efficiently with job errors virtually eliminated. Some RIPs can even collect job information and provide business statistics, such as how much media/ink has been used in a given period of time.

RIPs can do a lot more than just put dots on paper. Depending on your budget, you can have a barebones setup or something that can run a significant part of your operation. In many cases, you can start out with minimal features and add on as the need and budget arises. Take a look at what’s available today; you may be surprised.

PHOTO GALLERY (6 IMAGES)

Advertisement

In addition to doing the things RIPs usually do when digital printing, some can also aid with the placement of grommets for banners.

In addition to doing the things RIPs usually do when digital printing, some can also aid with the placement of grommets for banners.

Paula Fargo1 week ago

Paula Fargo1 week ago

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago

Columnists2 weeks ago

Columnists2 weeks ago

Eric E. Larsen1 week ago

Eric E. Larsen1 week ago

Heidi Tillmanns3 days ago

Heidi Tillmanns3 days ago

Signs of the Times5 days ago

Signs of the Times5 days ago

News1 week ago

News1 week ago

News4 days ago

News4 days ago