LEDs + Lighting

A Channel-Letter Comparison

We have two sets of channel letters — one with neon and one with LEDs — We then compare their brightness and ease of use.

Published

18 years agoon

With 22 years in the field, not surprisingly, I love neon. Quite simply, I enjoy all forms of light, and that would include LEDs. Their recent entry into the illuminated-sign field has caused many sign professionals, including myself, to step back and ask some basic questions about the future of illuminated signs and lighting.

So when ST asked me to scientifically compare covered LED and neon channel-sign components, I decided to conduct a test designed to measure the light output for each lighting technology.

Test parameters

What should we examine when investigating different lighting technologies? What might concern the average shop? How easy is it to assemble? How much does it cost? How difficult will it be to maintain? Will it produce enough light?

An architect or designer might wonder: How energy-efficient is it? What color ranges and effects are possible at what cost?

The architect or designer may have different concerns than the fabricator, but it’s the end-user who must ultimately be satisfied. An owner’s bottom line is: Will it attract clientele, will it be a good value?

AdvertisementMy test examines these basic questions about light output and energy input. After the installation cost is complete — and before the cost of repairing or replacing system parts occurs — there is, hopefully, a long period during which a useful and attention-getting, illuminated sign provides efficient and affordable service. I will answer some questions about the amount of visible light and the cost of producing it.

Channeling energy

My very simple test base was conducted with minimal equipment. Note that these investigative tests intentionally provide anecdotal information. A laboratory test involves significantly more thought concerning test structure and variables, many more sample types and test runs. A controlled experiment also requires equipment to be spectroscopically corrected because a color may have a different concentration of energy at a certain wavelength that my lower-cost sensor might not detect.

My tests don’t prove or disprove anything. Instead, I offer a short journey into making a few channel letters, illuminating them, reading a few meters and analyzing my findings.

The test comprises two, channel-letter cans with #2283 acrylic, transluscent red faces. One is lit with two rows of neon, and the other with the manufacturer’s recommended number of LED modules. The high-output LED — Permlight’s LED’R system — is relatively new to the sign trade. Currently, its best output is in the red range. While virtually all other neon colors are many times brighter and more efficient, I focused on red because LED and neon can be most closely compared in this color range. Also, red is commonly used in advertising campaigns to grab attention.

I chose the Permlight LED’R system because it was among the first on the market — I remember seeing its channel-letter display a few years ago at a tradeshow. Also, Permlight, which provides detailed technical data and product information, specifically recommends equivalency guidelines — namely two modules for every foot of neon. And the company sells a sample kit that includes everything needed to light a channel letter.

AdvertisementI used two, identical, covered, white, interior, 12-in., Helvetica channel letters. Specifically, I chose the letter "N" because I wanted to compare output levels and how well both light sources dealt with sharp turns. I fabricated an outline-style, 12mm neon letter and first tested it with a 3000V, 30mA standard magnetic neon transformer (operating current 24mA) and later, with a solid-state, 3000V, 50mA model.

Neon footage measured just over 5 ft. I used 10 LED modules, which didn’t fit quite evenly, and, thus, a portion of the letter received a greater density of light. Fortunately, this corresponded with the neon doublebacks and electrodes — also an area with a greater concentration of light — to foster a good comparison.

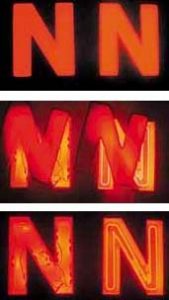

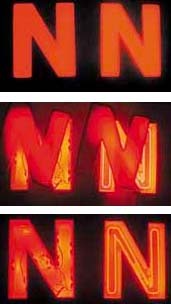

For my measurements, I used a foot-candle meter attached to a digital, true-RMS multimeter. Then I created as dark a space as possible and isolated the meter’s illuminated screen. Afterwards, I took a set of readings against the covers at seven points along the letter. I repeated these measurements three times for each different source for greater reliability. Because it’s a more common unit for light output as perceived by the human eye, I converted the readings to lux (lumens per square meter). $image1

Lusting for lux

When both units were powered, my eye told me the neon was much brighter. Therefore, I played with the LEDs at different heights and directions to see if I could maximize their output. The manufacturer’s recommended placement was indeed the best option.

From my subsequent meter readings, I obtained the following results: The average light output on the face of the LED-illuminated letter measured 464 lux, while the average reading for 12mm neon on a nominal 30mA transformer measured 1,439 lux. In this test, neon proved to be more than three times brighter (310%), so my eyes weren’t deceiving me.

AdvertisementI then measured the LEDs’ power consumption. My calibrated Fluke 87III meter read 730mA at 13.79V. At first, I was surprised to find nearly 50% higher consumption than the LEDs’ printed ratings. Then, I realized on-board resistors are required to regulate the modules. I also realized that different efficiencies depend on the power-supply design and whether or not it was fully loaded or partially used — thereby wasting some energy.

I measured approximately 10W power consumption on the transformer’s secondary side; a theoretical value, assuming 3% losses from an ideal transformer, would yield 10.4W. The actual AC current to the DC power supply used 17.85W. This shows the importance of fully loading a low-loss transformer with LEDs. Otherwise, power is wasted.

For comparison purposes, note that the wattage figures apply at the LEDs’ level of light — approximately one-third that of the neon letter. Thus, to properly compare neon with LED, we must multiply LED output by 3.1. We must also do the same with the wattage, as we can assume a linear relation. The measured neon voltage of 2065V at 24mA agrees with expected values. Given the transformer, the letter uses approximately 49.5W.

If we used the AC power consumed by the test kit, the result of 17.85W x 3.1 gives us 55W for LED. In this test, the neon letter (at 49.5W) is actually more efficient than LED.

If we assume better design conditions for a real-world system, and apply the same factor of 3.1 to the 10.4W, the system has a lower power consumption of 32.2W.

There are some trade-offs. To achieve a 33% reduction of watts at a comparable light output, we must use three times as many modules. The good news: This efficiency is possible. The bad news: The system will cost more.

I then tried a 50mA electronic neon power supply. The neon letter’s high output gave a reading of 2,250 lumens, while consuming 76.8W. The LED system would use only 50W to achieve that output, but nearly five times as many modules would be required.

Will LED replace neon?

My usual reply to this question is: Did the light bulb make the candle obsolete? Fortunately, a constant influx of new light sources must always be investigated to determine their best applications. As a theater professional who always works with various light sources, I know that each technology handles certain tasks better than others. Sometimes you can substitute one source for another, sometimes you can’t. Often, it’s the interplay between different types of light that makes a sign or an environment interesting.

Still in its infancy, the LED sign industry (electronic-message centers should be considered a different category) has a long way to go to match neon’s century of performance. Neon technology has benefited from its long existence — time and extensive usage have allowed its traits to be understood and its problems to be solved.

Plus, neon technology continues to evolve. Being the new kid on the block, the LED industry has little negative history. Novelty alone gives it appeal. But this industry may also run into unanticipated challenges — that’s true for any new technology. Undoubtedly, both technologies will continue to evolve, grow and prosper.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery3 days ago

Photo Gallery3 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks1 week ago

Benchmarks1 week ago6 Sports Venue Signs Deserving a Standing Ovation

-

Photo Gallery4 hours ago

Photo Gallery4 hours ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Megan Bradley

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Ashley Borell