ENGRAVING SEEMS TO be one of those services that went the way of the dodo bird. Is there anything sexy about it? No color, no flash and does it really have anything to do with making signs? Well, check out your server at many of the chain restaurants or the salesperson waiting on you at many different stores. A good chance those folks are wearing name tags that have been engraved. Okay, there is a lot of business for name tags, but what about signs? Public buildings must comply with ADA (Americans with Disabilities Act) rules. The little information signs you see posted everywhere use regular Roman text and Braille. Try printing those on your eco-solvent printer. Nope, you need an engraver. Many other applications make use of engraving too, including jewelry, license plate holders and various marketing items.

So what kind of a machine do you need to get into the business? Today you have several technologies to choose from, like pantograph, rotary, laser and impact printing. What you choose depends on what types of materials and functions you feel are the best fit for your customers. Let’s take a look at the features of each type of technology.

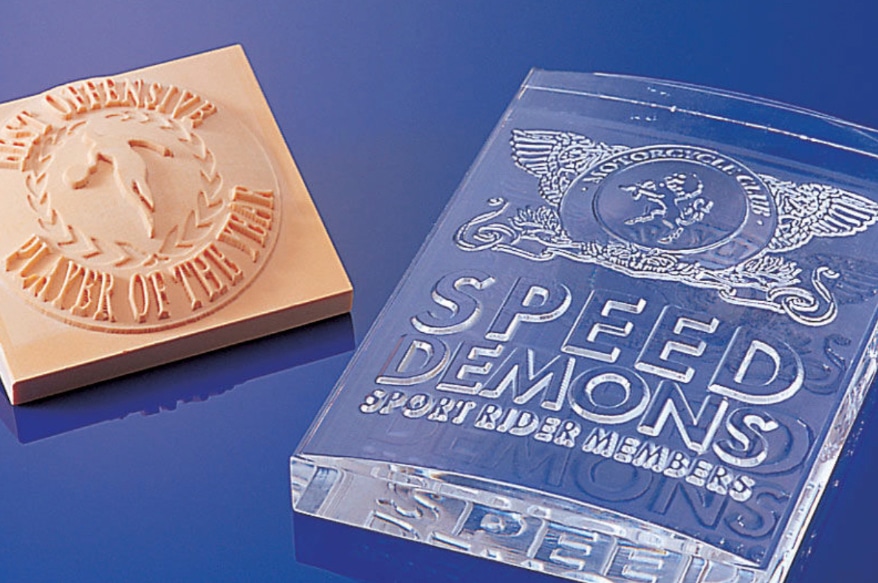

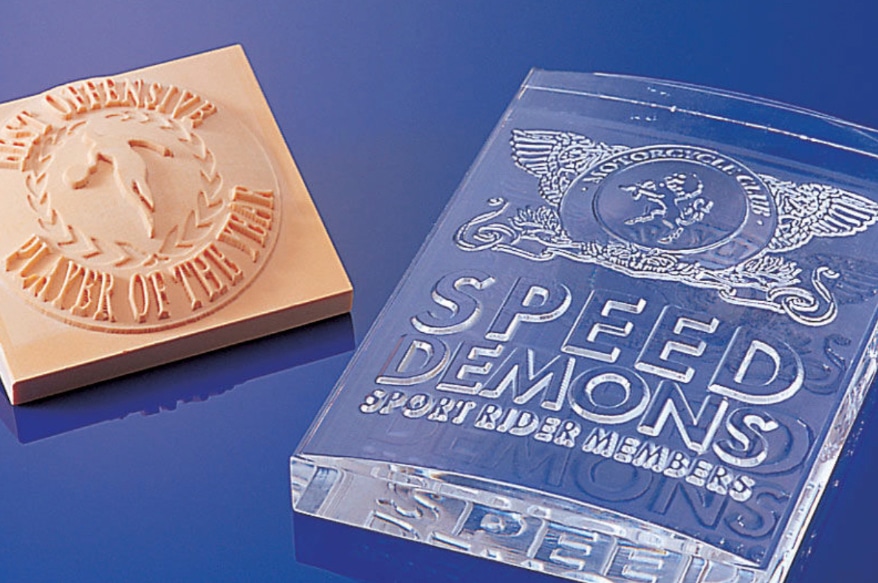

Nifty engraved projects like these demonstrate how well they fit signshop offerings.

Pantograph is generally the least expensive and easiest to use. The cutting mechanism is a rotary tool that uses different sizes of bits to determine line thickness. In essence, a set of alphanumeric slugs are used to build the text and an arm that allows you to trace the text onto the material is connected to the rotary tool. No real graphics and limited fonts are the big restrictions. No computer needed, easy to learn and a low price still make them attractive.

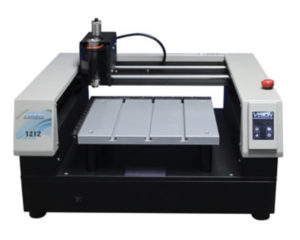

Rotary tool engravers use the same cutting method as the pantograph but tack on a processor and computer interface. They engrave plastics, light metals and wood with ease. Supplied software lets you design the text and graphics, and the machine takes care of cutting the job. These machines also handle Braille lettering by drilling shallow holes that accept balls to create the raised message. Some of the available software can even handle the translation from Roman to Braille characters.

When you read the title of this article, you may have thought about lasers, and indeed they are popular for engraving. For this discussion we are not referring to the large, high-power lasers that cut as well as engrave. Certain classes of lasers use diode-based, low-power lasers that handle wood, leather, plastics and even some metals. They have a small bed size and work best with softer materials. These are not the best choices for ADA signage, but the price and flexibility make them attractive.

Finally, we have a newer entry called an impact printer that even handles photographic images on metal. Using a print head composed of tiny spikes that strike an image into a tag, watch back or jewelry charms, these printers may add a differentiator to your shop.

Engraving is a great addition to many signshops. The cost is not extravagant, ranging from $3K up to $22K, but the added markets can make the investment well worth it. Check them out and see if one fits in your shop.

PHOTO GALLERY (6 IMAGES)

Advertisement

Photo Gallery7 days ago

Photo Gallery7 days ago

Ask Signs of the Times1 week ago

Ask Signs of the Times1 week ago

Paula Fargo4 days ago

Paula Fargo4 days ago

Real Deal1 day ago

Real Deal1 day ago

Benchmarks2 weeks ago

Benchmarks2 weeks ago

Photo Gallery4 days ago

Photo Gallery4 days ago

Women in Signs1 week ago

Women in Signs1 week ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago