We've all heard the news reports about depleted natural resources, teeming landfills and global warming. Talking heads have argued ad nauseum about the problems' severity and their causes, but people of most political stripes acknowledge that we should be mindful of how we consume and dispose of materials. Conservation and recycling are common practices in many households (sacrosanct in some), but, in the commercial arena, decisionmakers commonly perceive that "green" or "sustainable" – the latter has become today's buzzword for the long-term feasibility of materials and processes — and products are too expensive or unwieldy for mainstream use.

The sign industry has borne an unfair brunt of responsibility when resource scarcities have struck the United States During World War II, many on the home front viewed illuminated signage as an extravagance – and possible targets for would-be enemy bombers — and fabrication materials were readily sacrificed for the war effort (of course, many young signmakers were serving their country). During the 1970s, oil embargoes and gas-price spikes, some zealous conservationists advocated greatly restricting, if not outlawing, electric-sign use after business hours to conserve electricity. Thankfully, these and another long-ago initiatives, such as en electric-sign ban in Times Square, ultimately failed.

However, signage's increasing vitality and diversity – and generally positive public perception — carries a double-edged sword. More signage in more retail, civic and environments equates to more energy consumption and more public scrutiny. Although the sign industry represents a Lilliputian to other Gullivers (healthcare, hospitality, retail, etc.) Gulliver, opportunities exist to do our fair share to conserve energy and materials.

Frankly, the sign industry's newfound enthusiasm to adopt such methods currently outpaces its knowledge. There was a telling moment at last January's ST-sponsored Signage and Graphics Summit in Tucson. When an attendee asked a panel of end users about the use of recycled, energy-efficient or sustainable materials, the panel and audience didn't have an answer. Why? Signmakers follow the market. Until very recently, the market largely showed indifference towards such products.

However, that's changing. Whether a client has made a proactive decision to reduce his environmental footprint, must meet tightening environmental regulations or simply wishes to boost the company's image to gain a competitive edge, demand continues to grow for such new-generation signage. Though the sign industry remains on a sizeable learning curve, some manufacturers and providers have developed products that provide tangible environmental benefits. Some signshops have studied and implemented more ecologically oriented materials and methods. Though this is by no means an exhaustive, industry-wide treatise on the subject, here's a look at ways a few companies from various industry perspectives practice sustainable signamaking.

Advertisement

Light fare

Energy-efficient illumination has long been a sign consideration. Incandescent bulbs were supplanted long ago in most sign applications with brighter and more efficient systems. As LEDs have improved performance and gained widespread market acceptance, their energy-saving potential has prompted many customers to specify LEDs for their signage. Now, manufacturers have developed alternatives and modifications that augment LEDs' energy savings.

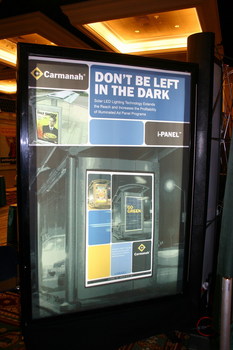

Earlier this year, Carmanah Technologies (Victoria, BC, Canada) introduced iPanel™, a 4 x 6-ft., transit-ad system that draws its power from an integral, solar-collection system. Brad Neufeld, the company's vice president of sales, said illuminating signage via solar power poses a significant hurdle, because harvesting and processing solar energy is relatively inefficient – Neufeld estimates approximately 20% that's collected would be retransmitted as sign illumination.

To combat this problem, Carmanah installed high-efficiency circuitry that reduced the "juice" required to power the system. The battery feeds the energy into a lighting system whose brightness amplifies across a reflective layer. To further conserve energy, he suggests dimming it to low power during daytime and turning it off during the wee morning hours that garner minimal visual impressions.

Neufeld said the grid requirements would depend on the panel's location: "In Florida or Arizona, the system will easily collect enough light energy autonomously for extended periods without sunshine. However, in Toronto, it would probably require a grid-power backup."

Solar-powered shelter ads may also provide opportunities to recoup the investment. Where installations require an electric-grid hookup, Neufeld said utility companies will typically pay the market, kilowatt-hour (kwH) rate for surplus energy that's fed back into the grid. In some jurisdictions, governments will pay a premium – for instance, Ontario pays seven times the kwH market price.

Advertisement

Lumigraphics (New York City) markets Light Tape®, an electrolu¬minescent (EL) system that provides accent or backlighting for POP displays. An alternating current applied to the rear electrodes excites encapsulated phosphors to produce light without generating heat. The system incorporates dielectric, conductive inks, and a fluoropolymer-barrier system protects the sign from the elements. Accord-ing to Lumigraphics President Jack Gallagher, the tech¬nology requires only 0.54W of power to operate one linear ft. and a daily operating cost of 24 cents for an indoor application.

EL graphics are prevalent throughout Asia and Europe, but Gallagher said the technology has scarcely been adopted in the United States: "There hasn't been the political or economic will to aggressively promote energy conservation in the past, but I think that's beginning to change."

Time-O-Matic Inc. (Watchfire Signs) Digital Outdoor (Danville, IL), a division of Watchfire by Time-O-Matic, produces LED bill¬boards. The company achieves significant energy savings through its development of boards that don't require air conditioning to cool and dehumidify the modules. According to Darren Friskney, director of Watchfire's digital outdoor division, its systems accomplish this through an air-return plenum that enables sufficient air exchange to ventilate the system.

"The silicone-gel encapsulation that surrounds the modules insu¬lates them against moisture that could raise humidity," he said. "The air flow can be regulated to adjust the temperatures. We tested our prototype in Yuma, AZ, where it encountered 120° F and experienced no problems."

Friskney said a 14 x 48-ft. digital billboard uses 188A at peak energy draw, which permits energy efficiency up to 16% greater than systems that run at 200 to 220A. Moreover, individually dimmable LEDs seldom require maximum energy. Further, the system allows programming up to 25% of peak brightness during overnight hours for further energy conservation.

Photo Gallery4 days ago

Photo Gallery4 days ago

Tip Sheet2 weeks ago

Tip Sheet2 weeks ago

Ask Signs of the Times6 days ago

Ask Signs of the Times6 days ago

Paula Fargo2 days ago

Paula Fargo2 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery2 days ago

Photo Gallery2 days ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago