I learned the importance of protecting overlaminates on bus markings more than 20 years ago when I sold a bus program to a city in central Illinois. The graphics were printed and clearcoated. However, within three months, the nylon bristle brushes used daily in the washing system had abraded protective clearcoats and inks right down to the base vinyl. The complaint went to court, and the plaintiffs won. The lesson of this story: Printed bus markings always need overlaminate protection.

Public vehicles, such as buses, are common targets of marauding vandals armed with cans of spraypaint. Specially coated PVC overlaminates can protect vinyl graphics from this urban artistry, but for extremely demanding applications, expensive polyvinyl fluoride (PVF) overlaminate films provide the utmost protection (Table 1).

Table 1: Characteristics of PVF Overlaminates

* Excellent for demanding applications

* Excellent outdoor durability

* Graffiti resistant

* Excellent UV protection

* Excellent abrasion resistance

* Very expensive

Because PVF is a low-energy plastic, paint has difficulty sticking to it. These films, which also provide excellent UV and abrasion resistance, are ideal for graffiti-proof markings, but because these films don’t stretch, they can be used only for flat applications.

Proper cleaning is critical in preserving PVF’s anti-graffiti properties. Clean dirty graphics with a nylon-bristle brush and citrus-based cleaner, such as Simple Green®. Solvents aren’t recommended because they can erode or etch the surface, which causes paint and dirt to stick to it.

Perforated window graphics

Advertisement

Perforated window-graphic films used for fleet identification should always be protected by an overlaminate, preferably cast-vinyl films. In addition to protecting the graphics from abrasive cleaning systems, overlaminates prevent dirt and water from collecting in the film’s holes, thus causing the adhesive system to fail. In all cases, the graphic’s outside edges should be sealed using a commercial edge sealer.

Tankers and cement-trucks

Increasingly popular, clearcoating and liquid laminates provide great short-term protection for promotional pieces, but they don’t outperform overlaminates. Graphics on chemical tankers are frequently subjected to chemical spillage. Acids, caustics and solvents can quickly erode the ink and clearcoating system of printed fleet markings, as well as leech the plasticizer from pigmented vinyl, embrittling it and causing the film to crack. Cement-truck graphics, which are easily damaged by caustic cement and harsh cleaning chemicals, should also be overlaminate-protected. $image1

Although vinyl overlaminates are usually best for vinyl markings, chemical tankers and cement trucks are an exception. For protecting markings subject to chemical damage, polyester overlaminating film was the best choice 20 years ago, and remains so today. Polyester exhibits outstanding chemical and temperature resistance — features that also make it an excellent protective film for warning labels (Table 2). But, because polyester isn’t conformable, it can’t be used over rivets, corrugation or compound curves. Furthermore, it shouldn’t be used to protect such flexible surfaces as awnings.

Table 2: Characteristics of Polyester Overlaminates

* High strength

* Excellent clarity

* Withstand high temperatures

* Excellent chemical resistance

* Outdoor durable

* Good abrasion resistance

* Rigid, inflexible

Graphics laminated with polyester also require special handling. To prevent tunneling, delamination or bubbles between the overlaminate and base film, graphics are best stored and shipped flat. During installation, take special care to avert delamination. Furthermore, to prevent edge lifting, graphics applied to the surfaces of tankers that haul caustic or petroleum-based products should be coated with a commercial edge sealer.

Advertisement

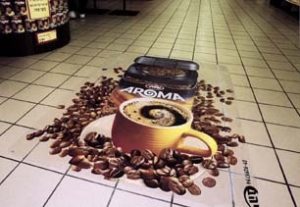

Floor graphics

Because floor graphics must withstand extraordinary abuse from pounding foot traffic, dirt, grease, grit and chemical cleaners, several types of overlaminates are designed for these applications.

Polycarbonate makes the best choice for floor applications because this tough, resilient film can withstand daily traffic, and its matte texture prevents slippage. However, polycarbonate film is expensive (Table 3). Thus, calendered vinyl overlaminate is an economical, but less durable, alternative. Whichever film you choose, all floor graphics should be waxed with a product recommended by the film manufacturer to prevent edge lifting.

Table 3: Characteristics of Polycarbonate Overlaminates

* Excellent for floor graphics, in-store graphics and exhibit graphics

* Withstand abrasion and rough handling

* When used for floor graphics, provide excellent slip resistance

* When used for in-store graphics, velvet texture eliminates glare from overhead lights

* Thick, rigid covering with excellent lay-flat characteristics

* Very expensive

To ensure that a floor graphic is slip-resistant, overlaminates are rigorously tested. The industry standard is American Standard for Testing Materials (ASTM) D2047. The ASTM test checks the overlaminates’s coefficient of friction, the force required to move one material over another. In essence, the test measures the traction a pedestrian could expect as he/she walks on a floor graphic.

Liability is a major concern for retailers, graphics producers and raw-material manufacturers. If a shopper falls on a slippery graphic, someone could get sued. Of course, the biggest litigation targets are companies with the deepest pockets. For this reason, some manufacturers provide an insurance policy with floor-graphic materials, which protects screenprinters, signshops and retailers from litigation ensuing from an accident. $image2

Advertisement

In-store, P-O-P and exhibits

As digital printing has grown in the sign industry, so has the use of overlaminates for signage, interior-wall and tradeshow graphics, and P-O-P applications.

Thick polycarbonate overlaminates are also often used for the protection of exhibit materials. This rigid protection offers excellent lay-flat characteristics, and its velvety texture eliminates any glare from overhead lighting. Polycarbonate can also withstand the rough handling encountered in tradeshow environments.

Vinyl overlaminates are offered in various finishes. These films cost more than polyester but are easier to laminate and less prone to bubbles and edge lifting. A cost-effective alternative to polycarbonate or vinyl, polypropylene overlaminating films now include a variety of 2- and 4-mil facestocks in several finishes. For display graphics, 5- and 10-mil polypropylene films are also available (Table 4).

Table 4: Characteristics of Polypropylene Overlaminates

* Moderate temperature resistance

* Good clarity

* Good chemical resistance

* Good durability

* Can be used outdoors

* Scratch easily

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery3 days ago

Photo Gallery3 days ago

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery6 hours ago

Photo Gallery6 hours ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago