Vehicles + Vinyl

Going Retro

How reflective vinyl can grow your business

Published

18 years agoon

Picture yourself sitting in traffic when an emergency vehicle rushes by in a flash of flickering lights. What do you see? Personally, I see dollar signs – no, I’m not a lawyer. However, I’ve been known to chase an ambulance just to see its high-intensity, retro-reflective striping and graphics.

In this column, I’ll be discussing the types and grades of retro-reflective vinyl, how they’re used and who’s using them. Also, this article glimpses into the not-so-distant future to explore new reflective-film capabilities and how they may translate to new business opportunities. This is a very exciting time for the reflective-film market.

To clarify, the terms "reflective" and "retro-reflective" are used interchangeably in the industry. However, their meanings vary slightly — retro-reflectivity measures light that’s captured after having returned to the source.

The latter term, reflective sheeting, actually comes from the transportation-sign arena. These manufacturers convert films to sheets for screenprinting and high-efficiency production of highway signage and license plates.

The players

Currently, four reflective-film manufacturers serve the market — 3M, Avery Graphics, Nippon Carbide Industries and Oracal USA. Also, there are 10 different classified, reflective film "types." So, consequently, standardizing procedures for these materials is complex.

AdvertisementThese companies manufacture myriad films for such diverse markets as fleet graphics and safety garments. Though some markets may overlap, the types of reflective films may vary greatly. Understanding their construction and type may help you decide which film may be best for your particular application.

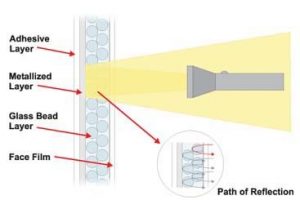

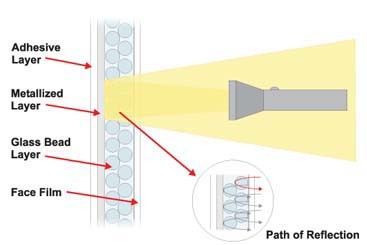

Glass bead or microprismatic are the main reflective-film categories. The first is the more recognizable, abundant and economical.

The film’s construction contains a layer of microscopic glass beads atop a metallized layer, which contains the film’s pigment. So, when a light source hits the film, it strikes the back of the glass-bead layer, and the metallized layer enhances its brightness.

Manufacturers produce this construction in economy, commercial, engineering and high-intensity (encapsulated-bead) grades. Each film’s durability and reflectivity dictate these grades, and the films are subsequently grouped into the Type I, II or III classifications, according to the ASTM Intl. (formerly known as the American Society of Testing and Materials) D4956 requirements for reflective-sheet materials.

The green background and the white letters of a highway-exit sign typically require a Type III, high-intensity film. Type II, engineering-grade films are commonly used for municipal street signage and most commercial, reflective graphics.

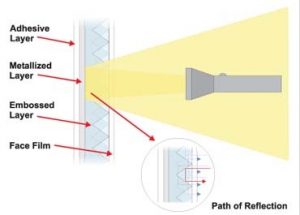

Another reflective type, microprismatic, is known for very high-intensity characteristics and greater light reflection than glass-bead materials. You’ve seen these films when passing a tractor-trailer bedecked with red and white markings. The media for these markings, known as conspicuity tapes, is mandatory for all commercial trailers that use U.S. highways. This construction contains an embossed, diamond-shape layer that allows the light to reflect at wide angles to improve visibility around corners.

AdvertisementMicroprismatic films have gained rapid acceptance in most states as the reflective film used for traffic and highway-safety signage and graphics. Microprismatic films comprise the ASTM D4956 Type IV through Type IX classifications — different prismatic constructions and backing, among other traits, distinguish the film types — and are offered in various colors and roll formats. However, they’re offered in fewer colors than glass-bead materials, and the construction may limit them to fewer applications.

Show me the money

Now, let’s examine what applications fit which films, and what types of shops produce these nocturnal graphics. Whereas such graphics, until recently, were produced out of necessity, reflectives are now increasingly used for everyday signage by clients willing to pay extra for greater sign visibility. For instance, Type I, economy-grade, reflective films are increasingly in demand for shorter-term, real-estate or construction signage. However, these films should only be used in flat applications due to their stiff nature.

Fleet graphics are probably the most identifiable flat application — common examples include EMS vehicles, police cars and fire trucks. City and county agencies may allow signshops some freedom in designing fleet graphics, and a commercial- or engineering- grade reflective film usually suffices for these customers.

In contrast, state vehicles are typically fitted with graphics at the state’s Department of Transportation before they’re placed into service. State agencies typically produce and install these graphics inhouse, and they incorporate at least engineering-grade films and, in many cases, feature high-intensity, microprismatic films.

AdvertisementCommercial fleet graphics have also fueled a surge in demand for reflective materials. McDonald’s exemplifies a company that heavily outfits its commercial trailers in full-color graphics. Commercial fleets provide an excellent opportunity to profit with reflective materials.

Until recently, reflective graphics were limited to the back doors of these trailers, because this was the only surface devoid of rivets or corrugations. Also, the back doors, the flattest part of the trailer, were most likely to receive direct illumination from a car’s headlights.

Older-generation film constructions could only be decorated via screenprinting or hard-solvent, digital printing. However, the films are changing with the times. Next, I’ll talk about what’s on the horizon and what opportunities may arise for signshops.

Come into the light

Earlier, I said 10 reflective-film types existed, but I only mentioned Types I to IX. The latest improvements in intensity have developed the new, Type X reflective films. A pitfall in current reflectives is the direction from which they’re viewed. I noted the film’s reaction to direct light from a nearby car’s headlights. As the light source’s angle moves closer to parallel to the graphic, light intensity fades until it’s completely gone.

Contrastingly, Type X films not only offer brighter, direct-light intensity than other films, but the intensity won’t degrade as the light source moves closer to parallel with the graphic. This is significant because, in addition to aiding traffic safety, it gives advertisers a much better avenue for spreading their commercial message 24 hours a day.

Printing on reflective films has historically been limited due to a couple factors. First, producing a consistent image required screenprinting, which usually requires very large production runs, or a full-solvent, digital printer that could aggressively bite into the film’s surface and overcome any surface imperfections. Of course, not every shop can afford the ventilation equipment these solvents require — not to mention afford the cost or accommodate the size of such machines.

Conformability and removability are other key considerations. Some films can conform over small rivets and corrugations, but their flexibility remains limited. When stretched too far, the layer of glass beads or microprisms can break and dim reflectivity. Even if you’ve enjoyed a successful installation, what happens when it’s time to remove the graphic? Likely, an adhesive-removal nightmare.

What if we could overcome all these obstacles? This year, films will hit the market that help installers overcome those hurdles and produce applications previously thought impossible. New-age reflective films will enable users of mild-solvent, eco-solvent and UV-curable printers to produce reflective images in a consistent, reliable and productive manner. These films will eliminate removals that most shops fear and loathe.

Further, a film with this type of engineering will allow fully wrapped, reflective vehicles that will conform over fenders. Imagine a city bus that gleams from one end to the other, a nighttime car race or an all-night ice-cream truck (maybe the last example is a bit much). Reflective-film manufacturers have made some revolutionary breakthroughs in the last couple of years, and you and your customers can benefit.

Prepare yourself

Industry veterans are fully aware of how quickly technology and applications change and evolve. The reflective-film market is a classic example – born from necessity, these films have evolved and opened opportunities for graphic providers like never before. To take advantage of these opportunities, users must stay aware of these developments as these products are brought to market.

Further, if you plan on getting more involved in this market, make sure you understand your state’s regulations regarding what types and grades of reflective films are approved for use. And, as I always preach, make sure to do your homework — review technical bulletins that address product processing and handling. Reflective films require special considerations.

May the reflective force be with you!

Craig would like to thank Natalie White, Oracal USA’s product manager, and Henry Lacinak, materials testing and evaluating engineer for the Louisiana Dept. of Transportation, who helped provide information for this article.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

NUtec Digital Ink Invests in Solar Energy for Facility

5 Reasons to Sell a Sign Company Plus 6 Options

21 Larry Albright Plasma Globes, Crackle Tubes and More

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet2 weeks ago

Tip Sheet2 weeks agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery3 days ago

Photo Gallery3 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Paula Fargo22 hours ago

Paula Fargo22 hours ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Benchmarks1 week ago

Benchmarks1 week ago6 Sports Venue Signs Deserving a Standing Ovation

-

Photo Gallery22 hours ago

Photo Gallery22 hours ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Megan Bradley