First commercialized in the 1970s, LED lamps found initial use as indicator lights in consumer products. As the technology improved, light output increased, and other colors became available. The next notable deployment occurred in the mid-1990s, when exit and traffic signmakers adopted LED lamps. Such easily installed applications proved effective.

Today, LED marketers have projected giant growth claims –one forecasts an aggregate revenue growth of approximately $11 billion by 2012 for high-brightness LEDs in signage, display and illumination industries. Nonetheless, the current technologies will remain effective for some time.

This isn’t true for LED-based traffic signs, because, in such applications, color binning and infrastructure shortcomings are acceptable. Further, LEDs’ benefits over incandescent are obvious: They are brighter, last several years and use less energy.

Consequently, most U.S. cities are upgrading their incandescent traffic lights with LED units (many have already converted). The upgrade advantages are:

• Brighter: The LED arrays wrap the entire traffic light surface with equal brightness, thus increasing the overall (comparable) brightness.

• Longer lasting: LED units can last several years. Fewer truck trips save big dollars.

Advertisement

• Energy efficient: LED lamps cut electrical wattage by at least 70%.

Many new traffic signals contain LED arrays. In these, the individual LEDs are small, about the size of thumbtack head, which allows hundreds to be arrayed as a one-light source, when seen from a distance. If a traffic light uses 100W bulbs, it will consume 2.4 kilowatt-hours of energy per 24-hour day. Assuming an average cost of 10 cents per kilowatt-hour, one traffic signal will cost 24 cents a day to operate, or about $88 per year.

Intersections typically have 12 traffic signals, which means at least $1,000 per year. A big city has thousands of intersections; hence, it costs millions of dollars to power traffic signals. (Commercial-energy costs vary across states – for example, New York, Massachusetts and California pay twice the rate of Minnesota – see www.energy.gov.)

Conservatively speaking, today’s LED bulbs could drop energy con-sumption by a factor of five. In the future, as technology increases the LED efficacy, they may consume only 5W. Even today, large cities can save more than a million dollars annually, by replacing traffic bulbs with LED units.

LED bulbs are also suitable for standalone, solar-panel feeds, which avoid remote-area, electrical-line routing and save money.

Advertisement

Benefits

LEDs’ five-year-plus lifespan is often extended (unintentionally) because many arrayed LEDs remain lit after others have burned out. Incandescent lamps die suddenly; LEDs gradually dim. This characteristic gives advance warnings to maintenance crews, so they can schedule a lamp change.

Because they’re dimmable, LEDs can function at high brightness, when intense sunlight is present, and at reduced brightness at night (or during gloomy weather). And, engineers can design arrays that display multiple patterns and colors, which may be desirable for some applications. (Individual, color-changing LEDs are much less established than the standard, multi-color-array technology found in RGB displays.) Finally, LED lamps switch faster than incandescent and fluorescent lights.

Replacement options

When purchasing LED-based lamps, buyers can easily select the best-suited technology. However, as existing bulbs fail, LED retrofits are a suitable, intermediate option. This choice deflects initial installation costs and reduces ongoing maintenance costs.

Retrofits can use a Central Light Source (CLS) optics technology. It comprises approximately seven, white, high-output LEDs (~ 1W) placed behind the lens; a diffuser disperses and broadens the light, which causes a uniform appearance across the lens face. Such systems are similar to traditional halogen or incandescent luminaires.

Advertisement

The benefits of replacing halogen or incandescent lamp assemblies with a CLS-LED ensemble are minimal disruptions, plus labor and material savings over several years.

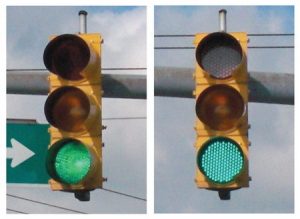

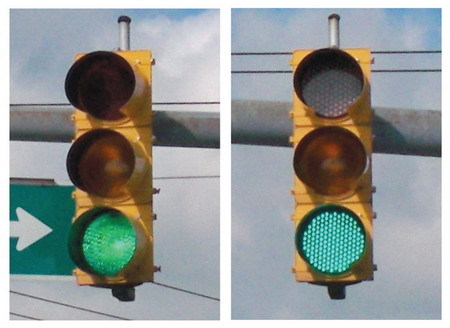

I‘ve noticed such retrofits residing alongside standard, LED-based units at the same traffic intersection. You can see (Fig. 1) that one traffic light shows visible LED arrays, while another still looks as though it’s incandescent based. So, behind the lens – is it incandescent or a CLS-type LED arrangement?

This raises an interesting question: How do you determine if LED lamps have replaced a system’s incandescent lamps? This occurs in traffic, office, building and sign (both cabinet and channel-letter) lighting.

Here’s the truth: You often can’t. Not from the outside, anyway. However, if the sign face or the luminaire doesn’t include a light diffuser, and if the optical path beyond the LEDs is transparent, you should see the LED arrays. The bad news occurs when a translucent material filters the LEDs. Such lenses may block any telltale indicators.

Some argue that LEDs switch on and off faster, with no afterglow, but this method may fail if a thick lens is present.

Economic challenges

LED traffic lights, on average, reduce costs 80% when compared to traditional, incandescent systems. Furthermore, electricity rates routinely experience annual increases and, by 2010, will likely run 35% higher than today. Such financial attributes lead lighting buyers to seriously consider LED lamp systems.

The LED-upgrade payback, at today’s electricity rates, is approximately three years. The electricity and maintenance cost savings will justify the initial investment. Some federal and state transportation programs offer grants as well as technical assistance for LED-lamp upgrades.

Signage-industry parallels

Although I expect a full LED conversion for traffic lights in the next few years, I’m sure more time will pass before we see the signage and lighting industries altogether embrace LED lamps for widely illuminated signs.

However, the sign industry should study the traffic-light upgrade and change-out processes. It may want to learn more about such systems’ retrofitting, usage and maintenance, because the LED lighting industry has undergone (and is still going through) considerable standardization processes. Although such items as lumen maintenance and chromaticity parameters now have specifications, many other aspects of solid-state lighting are not yet standardized. The LED traffic lights are no different. Professional standardization of traffic lights, overseen by the Institute of Traffic Engineers (ITE), also requires time and effort.

UL is the most recognized body for electrical and safety requirements, and it’s addressing LED sign requirements. (A formal body such as the ITE doesn’t exist for the signage industry.) More work is necessary for signage LEDs, to standardize such facets as brightness, color, size, electrical controls, viewing angle, outdoor durability, electrical and optical-system requirements and more.

Standard adoption, educating and training technicians for LED-lamp integration and maintenance, as well as budgeting for studies, are areas where the signage industry can draw parallels from the traffic-lighting industry. Eventually, LEDs will become the prevailing choice for sign illumination.

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks ago

Paula Fargo1 week ago

Paula Fargo1 week ago

Real Deal5 days ago

Real Deal5 days ago

Photo Gallery1 week ago

Photo Gallery1 week ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Projects5 days ago

Projects5 days ago