Digital Printing

Roll On, Stars and Stripes

Published

14 years agoon

More customers now seem to ask for American-flag designs for their vehicles. Maybe it’s because people are becoming more patriotic due to concerns about the government. Or, maybe it’s simply because my shop is located approximately 30 minutes from Washington, DC.

Red, white and blue always provide an easy color scheme. White and blue never pose a problem, but red sometimes provides an issue during the digital-printing process.

To print a vivid, bright red requires 100% magenta and 100% yellow inks – however, this combination produces a tomatoish orange-red. Print out a color chart, and use this as a color-matching guide; don’t just rely on your monitor’s color palette.

I use aftermarket Lyson 1300 Series ink with my Mimaki JV3-160SP printers. I’ve tried many ink vendors; I’ve even ordered ink directly form China and Hong Kong. I’ve learned cutting corners on ink quality is a bad idea. Meeting customer demand requires quality inks.

Riding out the storm

My latest patriotically themed project arrived two days after the largest snowstorm in 100 years hit northern Virginia. It dropped 30 in. of snow on my shop and left us without power for five days. This was a major problem. Living conditions resembled camping. We used flashlights for light, cooked on a wood stove and melted snow for water. It got old very fast!

AdvertisementBecause my printers had no power, I was concerned about the heads drying and clogging. I put cleaning solution in the printhead caps to make sure they didn’t dry up. I also flipped our electric breaker box to “off” so, when the power returned, a surge didn’t burn up the printers’ circuitboards. For two days, I removed snow using my shop’s Skid-Steer, multi-purpose, lifting and moving vehicle. It also proves handy when taking large objects, such as digital printers, off trucks. I mainly use it for moving large trailers in and out of my shop to wrap.

My client drove four hours to my shop – proof that a reputation for quality work will motivate customers to travel for your services. The customer, Jim McKelvey, is a real-estate developer who’s running as a Republican congressional candidate in Virginia’s 5th District. He wanted us to decorate his colossal RV with a wrap that proudly announces his candidacy. After I spent a few hours cutting some fallen trees and spreading some salt and gravel, the RV gained enough traction to navigate the long driveway into my shop.

My methods

I usually give my customers four designs from which to choose. I design everything in PhotoShop® and bounce between Adobe Illustrator and the web, where I reference and acquire stock photos from such sources as Stockphoto.com or gettyimages.com. I also use Alien Skin software for such effects as chrome lettering and brushed-metal textures.

Then, after I get vehicle into my shop, I take photos and finalize artwork. This lets the customer know exactly how the finished product will look. It’s better to design with the actual vehicle’s photo, versus a line drawing. Sometimes, vehicles have aftermarket body molding and other design obstacles on them that aren’t accounted for with line drawings.

AdvertisementOnce the customer approves the design, I take accurate measurements to verify exactly how the wrap will configure when it’s applied. I own vehicle-template software, but seldom use it. I reference photos of the customer’s vehicle. I don’t want any text to be rendered illegible because of an interfering door handle or object.

I power-washed the whole vehicle and scrubbed the entire surface, especially hard-to-reach nooks and crannies, with an alcohol solvent. Next, we applied 3M’s Primer 94 to such problem areas as around window trim and door handles. The primer helps the vinyl adhere better in those areas.

Our shop simultaneously ran three Mimaki printers – one printer for each vehicle side, and the third produced graphics for the front and back. The full wrap measures approximately 890 sq. ft.; 340 sq. ft. on each side, 110 sq. ft on the back, 75 sq. ft. on the front, and a few more for the bumpers.

Running multiple printers at once speeds up the process by at least a day for large-truck projects. Everyone wants everything ASAP. I do all I can to work efficiently, but I make it clear to my customers that you can’t excessively rush the creative and production processes.

The right stuff

AdvertisementFor the wrap’s sides, I used Arlon’s DPF 4560 GTX vinyl. After having used 3M vinyl exclusively for many years, I’m experimenting with different media for each application. I like Arlon’s product because it doesn’t stretch much, which helps wrap seams register easily.

The black adhesive blocked out the RV’s existing stripes. The Arlon media’s X-Scape® air-release technology minimizes air bubbles and tenting. The sides of the RV were flat, so stretching wasn’t required. Price was a consideration, and the wrap would only required a lifetime of months, not years. Thus, a calendered film proved capable.

However, for the vehicle’s front and back, I used 3M IJ180c Controltac with Comply V3 cast, air-egress film. In my opinion, this media offers the best choice for wrapping over tricky obstacles, such as bumpers. Because of the project’s short lifespan, a topcoat film wasn’t required, although I did apply my proprietary, clear, UV- and scratch-resistant coating to the surface.

Each side required 8- to 10-ft.-tall panels with a ½-in. overlap from top to bottom. I laid down a long piece of masking tape along each side to serve as a straight-line guide. Make sure your first piece is straight; otherwise, your line will slowly slide as you move down until it’s several inches askew at the other end.

Before printing such a large project, I output some small versions of the project on banner material and test vinyl to ensure I liked the colors before running the printers on full production. I give these small samples to the customers for free. Everyone loves free, promotional banners and decals.

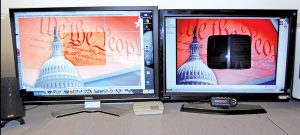

After we applied the wrap to the truck, I cut around all the windows and photographed them. Now, using a dual-monitor computer system, I put my wrap graphic on one monitor, and the photo of the wrapped vehicle on the other. This way, I can see exactly where I need to crop the file to output LG Vizuon LM50000 perforated-window film. This can save you money because you’ll have minimal waste on this expensive film.

When you remove vinyl from the windows and wheel wells, hang a clothesline in your shop to save a few pieces until the wrap is completed. You may need a small piece of a certain color to patch a flaw.

After the project is complete, I use large, body-shop heat lamps to bake the wrap onto the vehicle after application. I primarily use heat guns, but, when I have to wrap a bumper, these large lamps evenly heat a large piece of vinyl. Two people can stretch it over the whole front of the car at once, a real time-saver. Then, I use these large heaters to relax the vinyl and prevent its “memory” from returning to its original, unstretched state. These lamps employ timers, so you don’t overheat the vinyl, and they warm the surface evenly. Use this system cautiously; the lamps get hot and shouldn’t be placed too close to the vehicle. I keep them about 2 ft. away from the vehicle and don’t walk away from them.

When the project is finished, I place my contact info on the vehicle. With the customer’s permission, I apply a 4 x 2-in. piece of vinyl with my logo – black for light-colored vehicles, and white for dark ones. This is a very inexpensive way to market your wrap business. After the project was completed, I celebrated with a short fishing vacation in Costa Rica to get away from the snow.

Virginia’s political primaries take place June 8. If Mr. McKelvey’s campaign successfully advances to the general election, it will be gratifying to know my wrap played a key role in his campaign. He and his campaign managers were impressed and have referred me to friends of theirs in the political arena. I’m also producing bumper stickers, yard signs and banners for McKelvey’s campaign.

Equipment and Materials

Design: Dual-monitor Mac Pro computer system from Apple (Cupertino, CA), (800) 692-7753 or www.apple.com; special-effects software, from Alien Skin (Raleigh, NC), (888) 921-7546 or www.alienskin.com; Photoshop® and Illustrator® software, from Adobe Corp. (San Jose, CA), (800) 833-6687 or www.adobe.com

Printer: JV3-160SP solvent-ink printer, from Mimaki USA Inc. (Suwanee, GA), (888) 530-4021 or www.mimakiusa.com; Lyson 1300 Series inks, from Nazdar (Shawnee, KS), (913) 422-1888 or www.nazdar.com

Tools: RollePro vehicle-wrap tool, from G Force Products LLC (Greensboro, NC), (336) 289-5012 or www.rollepro.com; industrial-strength, body-shop heat lamps, from Infratech (Gardena, CA), (800) 421-9455 or www.infratech-usa.com; ladder system, from Little Giant Ladder Systems (Springville, UT), (801) 489-3684 or www.LittleGiantLadder.com; and rolling staircases and metal support beams, available at home-improvement stores

Vinyl: DFG 4560 GTX air-egress vinyl, from Arlon (Santa Ana, CA), (800) 854-0361 or www.arlon.com; Controltac IJ180-10C with Comply v3 air-egress film, from 3M (St. Paul, MN), (888) 364-3577 or www.3m.com; Vizuon LM 50000 perforated, window film, from LG Hausys (Englewood Cliffs, NJ), (201) 816-3089 or www.lghausys.com

More About Scott

Scott Lewczak, proprietor of Artworks Signs & Autowraps/www.signfarm.com (Nokesville, VA), airbrushed his first van at age 12. His work evolved to encompass vehicle wraps, dimensional signage, banners and logo design. Lewczak has won several awards for his vehicle-wrap designs, including First Place in the Promotional Graphics category of ST’s 2009 Vehicle Graphics Contest for Signfarm’s production of a Smart Car wrap for Mike Garcia Construction (see ST, December 2009, page 74).

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo1 week ago

Paula Fargo1 week ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal5 days ago

Real Deal5 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Alicia Brothers

-

Projects5 days ago

Projects5 days agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza