Soft Around the Edges

Today’s fabric signage expands to meet a flexible market.

Published

3 years agoon

IF THE YEAR 2020 could be summed up in one word (and this word needed to be suitable for readers of all ages), we would say it should be “adaptability.” There is almost nothing static about anything that’s happened this year. Much like the fabric used to make soft signs, we’ve all had to be accommodating to change and be flexible in our plans.

Luckily for the industry, soft signage has grown steadily over the past decade. In fact, the output of digital soft signage printing was predicted to increase by about eight percent between 2015 and now, according to a study done by consulting firm I T Strategies.

So, while we’re all adapting to fabric face masks, the following three companies have also been changing soft signage to meet customer needs, creating fabric signs to convey messages in ways that would have otherwise been more complicated, time-consuming and costly than their inflexible counterparts.

TOWERING ABOVE THE COMPETITION

Although Fusion Imaging (Kaysville, UT) might best be known for producing their self-entitled “big time graphic” solutions at venues ranging from the Olympics to the New York Marathon, to the Clinton Foundation’s Global Initiative to the former Las Vegas Raiders’ stadium in Oakland, some of their smaller-scale work can also be found nationwide at retail shops such as Old Navy and Best Buy.

It was this more compact (though still just as eye-catching) retail work that first attracted new client 7 For All Mankind in Fashion Island mall in Newport Beach, CA to the shop this year, as they were seeking custom light boxes for their storefront window. “We were able to partner with 7 For All Mankind because we could offer a variety of substrate solutions including SEG/fabric,” said Kelly Taylor, Fusion’s director of marketing and creative services. “We [also] make custom light boxes, so that’s what generated this concept.”

At the project’s start, the client asked for a tower lightbox and supplied a photo of something they had seen along with the artwork they needed and asked if Fusion could create it. “Our team, through renderings and engineering, developed their idea into an actual display, complete with lightbox sections, digital integration, etc.” Taylor said. The incorporation of video that the client needed in addition to the soft signage made this project trickier than initially thought. To that end, Fusion purchased smart TVs and leveraged their internal software to run the store’s digital content, which was supplied by the client. In total, Fusion shipped similar displays to 30 locations across the country.

Advertisement

Fusion Imaging (Kaysville, UT) generated custom light boxes and other digital integration for their client 7 For All Mankind’s store at Fashion Island mall in Newport Beach, CA, as well as 29 other locations nationwide.

Fusion incorporated SEG Samba backlit textile fabric, which was fabricated using the dye-sublimated printed fabric on an EFI VUTEk FabriVU 340 and cut on a Zünd G3 3200 XL cutter. All frames were made using Fusion’s custom extruder. They also used their proprietary KLIK magnetic connectors for assembling the boxes, so the frames were able to be stacked and stay put using magnets. The televisions were made by Insignia and other additional campaign materials were sourced from Sintra boards and standard magnets.

Because Fusion provided detailed instructions and video to assist all 30 locations with installation, and the displays were built so that each store could construct its own signage without any additional install workers, the project was assembled in-house by the store’s employees in one day over the course of a few hours, Taylor said.

Taylor added that no matter if you’re dealing with graphics large or small, the top-selling points of soft signage include the ease of being able to change the graphics out and the shipping-cost savings over flat rigid graphics.

CANVASSING THE ENVIRONMENT

When agricultural company Syngenta’s design firm StagHill went searching for a signshop to help with their environmental branding project, they first turned to the good old Google search bar to find an Illinois-based service provider that worked in large-format printing. And that’s how Cushing (Chicago) came to be vetted alongside about half a dozen other shops, eventually standing out to win the project, which was to create a series of canvas prints that fit into the client’s overall environmental branding project, according to Jon Davis, Cushing’s marketing manager.

To narrow down the signage needed at Syngenta’s Downers Grove, IL office, Cushing Account Manager Christine Fetting consulted with the company on all the facets of the office’s needs, including privacy film, wall graphics, entrance graphics and the ornate canvas prints.

AdvertisementDavis suspects they were able to sell Syngenta on the canvas prints because “[They’re] an art-based product that’s great for textured looks and branding,” he said. “It adds an art dimension and feel, even if it’s not genuine or original fine art. [Also] canvas is versatile and can be wrapped or framed. “The client had a lot of open wall space and blank walls to work with and the canvas proved a great feature and focal point to the wall and provided quite a bit of “pop,” he added.

Cushing (Chicago) worked with agribusiness Syngenta to create ornate signage on canvas prints as part of the office’s environmental rebranding project.

However, as versatile as working with canvas is, the project didn’t come without challenges. Because “Syngenta” was spread across four separate canvases, getting the name to line up across the different levels and appear in line from afar required detailed measuring. “It had to be precise, like pieces of a puzzle,” Davis said. “We had to drill into the wall and hang the canvas on cleats on the back of the prints. If something had been a little off with a measurement, it could have affected the symmetrical look and feel.”

While the client provided the print-ready files, Cushing added bleeds to the sides so the artwork could be seen from all angles. They used Magic GFCVM canvases (which are meant for receiving solvent ink) and printed on an Epson SureColor S80600 printer because it contains 10 ink colors, which provide an accurate color depiction necessary for the large gamut of colors the branding possessed, Davis said.

Cushing used a Zünd digital cutter to create the finished flat piece, which was then wrapped around a wooden frame. After the signage was finished, they transported the prints to the client’s office. The installers then situated a variety of pieces from the canvases, wall graphics and window film as well.

Davis thinks his client’s use of signage is on trend, as he said he is seeing more and more customers “going beyond just a dimensional piece [to] incorporate soft signage with a logo that includes images of customers and photos that support their brand,” he said. “It is truly being used as a way to extend a brand around the office.”

AdvertisementA CIRCUS ADVENTURE

Some would say Las Vegas houses the lion’s share of concentrated signage in the country, which makes the city quite the conundrum for local marketers trying to make sure their clients stand out in an oversaturated market. When Circus Circus Hotel and Casino wanted to attract attention to their Adventuredome indoor theme park preview center, they reached out to their marketing company, Social Butterfly World, for help. Social Butterfly then turned to their longtime fabricating partner, Color Gamut Digital Imaging (CGDI; Henderson, NV) , to help them with their initial idea, which was to wrap a few walls at the facility.

“The room we were [to] work in had a number of contoured walls and an office inside that was not being used,” CGDI owner Pamela Richards said. “Originally they were trying to wrap all the walls in vinyl including the office, [making] the complete area 3D. This was not going to work. [However], once we showed them what we could do using soft signage, they were sold on the idea.”

Color Gamut Digital Imaging (Henderson, NV) was able to tame a complicated space at Circus Circus Hotel and Casino’s Adventuredome indoor theme park preview center with lots of colorful soft signage.

From there, the customer took the concept Richards suggested and hired an outside 3D designer to create the layout. Using software from Adobe Creative Suite to finalize the layouts, Richards’ team used a soft stretch fabric by Fisher Textiles for the majority of the wall designs and printed them on an EFI Reggiani printer driven by Caldera RIP software. The floors of the preview center were created on vinyl floor graphics printed on an EFI VUTEk LX3 Pro using EFI Fiery RIP software. CGDI put everything together using beMatrix frames and installed it over two days.

Richards isn’t surprised that CGDI has seen a 40% increase in soft signage sales recently. For one, she said soft signage allows for more creativity in the art, and the look is very clean compared to the rigid side of the business. Soft signage also has allowed them to broaden their imagination and expand to meet a more flexible market. Being able to reuse the product is a great selling point, too. “Soft signage can be used over and over if cared for properly. It is easy to clean and easy to store for later,” Richards said.

Elizabeth A. Lowry is a freelance writer from Cincinnati, OH. She has been writing about the sign industry for more than 20 years. Contact Elizabeth at elowryeditorial@gmail.com

SPONSORED VIDEO

Who’s Steering Signs of the Times?

We dive into the history of the sign industry’s oldest trade journal, highlighting some interesting facts about how it all started to where it’s headed. Did you know that Signs of the Times is nearly 120 years old?

You may like

Advertisement

Canon U.S.A. to Host Webinar on AI Integration in Business

21 Highlights from the American Sign Museum Main Street Expansion

From Chips to Hip

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Advertisement

Most Popular

-

Tip Sheet2 weeks ago

Tip Sheet2 weeks agoSign Tips for Construction Fence Graphics and CNC Tables

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Wrap Shop Plots to Take Back a Poached Installer

-

Paula Fargo3 days ago

Paula Fargo3 days agoSelling Your Sign Company Via the Franchising World

-

Photo Gallery20 hours ago

Photo Gallery20 hours ago21 Highlights from the American Sign Museum Main Street Expansion

-

Signs of the Times4 days ago

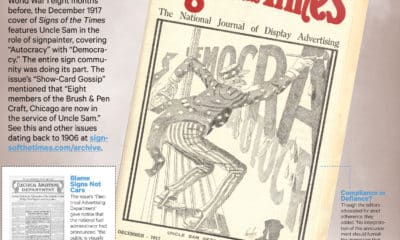

Signs of the Times4 days agoDecember 1917 Signs of the Times Cover: Safe for Democracy

-

News1 week ago

News1 week agoMUTOH Introduces New Single-Pass ADA Features

-

Special Report1 week ago

Special Report1 week agoThe Wide World of Non-English Signs

-

News2 weeks ago

News2 weeks agoWells Fargo Sign Removed From Jacksonville Tower