LEDs + Lighting

Efficient LED Sign Illumination

Knowledge generates customer satisfaction.

Published

15 years agoon

LEDs have gained popularity among signmakers, according to ST’s 2008 Lighting Survey (see ST, March, page 76) and, in some cases, the illuminated-diode applications have exceeded neon’s marketshare. Undeniably, LEDs’ continuing technological advances are producing attractive, alternate lighting sources for electric signs; thus, sign designers and end-users have additional lamp choices for their illuminated-signs.

The Lighting Survey shows 68.4% of the LEDs used by signmakers are for channel letters. It also indicates, for the first time, that signmaker’s use of white LEDs has surpassed red (46.9% vs. 40.5%).

Compared to neon lighting, LEDs’ channel-letter and cabinet-sign illumination advantages are: reduced energy use, longer lifetime ratings, more flexible patterning, less breakage, lighter weight and easier maintenance. Unlike neon tubes, the LEDs are durable and easily installed. Such systems comprise small, discrete modules, which can be connected in either parallel or serial fashion, via electrical wire strings. This module/wiring feature allows for variable layouts and easier lamp replacement.

In addition, retrofitting neon-illuminated channel letters with LED sources is feasible because LED systems are modular and can be cut to size in the shop or field, to fit the needed shape. Installers can easily attach modules with pre-applied, self-adhesive tape, or they can mechanically affix them to the channel-letter back. An accompanying, low-voltage (12VDC) power supply, connected with Class 2 power wires (10-12 AWG), may be placed inside or outside the channel letters.

Many companies are finding that replacing the old neon with an LED system is cost effective because of lower maintenance costs and reduced energy consumption.

Disadvantages

AdvertisementDespite these notable advantages, LEDs struggle with brightness, color quality and uniform illumination. White-LED disadvantages are even more pronounced. They also suffer from inadequate luminous efficacy, brightness, color rendering and consistency in the white color – otherwise known as the “color binning” problem. These faults can affect a sign’s final image.

Such inconsistencies also increase white LEDs’ costs.

Over time, however, technological advances will overcome these disadvantages. Meanwhile, signmakers can apply some measures, today, to achieve greater channel-letter illuminance, as well as improve uniformity and color quality.

Illuminance is the amount of light, from a light source, that falls on a surface. Its measurement essentially tells us how well a surface (a signface, for example) is illuminated.

Choosing LEDs

LEDs are available in single colors: red, amber, yellow, green and blue. White LEDs are produced using various, color-mixing techniques, some of which include phosphors. Unquestionably, red LEDs perform best, and, consequently, are the most popular color choice for signmakers, contrary to the Lighting Survey’s results.

AdvertisementA signmaker should select LED lamps based on the sign-face size and how well the module can illuminate it. This choice depends on crafting an optimal design, one that involves the size and number of LED modules, their brightness, and the distance between the LED modules and the sign face.

Although many LED manufacturers and retailers tout ‘super bright’ LED modules and lamps, sign viewers – the person on the street – won’t detect such pronounced brightness or even appreciate it. Passersby will appreciate conspicuity and visibility, the features that depend on the brightness level, uniformity and color quality of the sign face. Should sign fabricators try to improve uniformity and contrast by using excessively bright LEDs, they will produce glare and visual discomfort – and waste energy.

Buyer satisfaction

Illuminated channel letters must reach certain brightness levels to satisfy a buyer’s expectations. To quantify brightness, luminance, usually measured in nits (candela/square-meter: cd/m2), is used. To properly illuminate a channel-letter face, each LED-lamp module used in the string must be bright enough to radiate the required amount of light.

(Note: “Brightness” is not quantity – it is physiological sensation; when we quantify it, we use luminance.)

Success is best gained when a sign designer determines and specifies the illuminance (the amount of light incident on a sign surface) in lux or footcandles, to ensure that the desired amount of light hits the sign surface.

AdvertisementLux is measured in lumen/square meter (lm/m2).

Optimized illumination

To simplify matters, consider only normal incidence, where luminance and illuminance are related as the following (Reference: IESNA TM-11-00):

Ev = (L x S)/(D*D) Eq. 1

where Ev is the illuminance, L is the luminance of the lamp module, S is the surface area of the lamp, and D is the normal distance from the center of the lamp to the center of the illuminated surface. This is essentially the well-known inverse-square relation that Swiss German physicist Johann Lambert (1728-1777) helped formulate.

Because many lighting designers use feet for measurements, rather than meters, this equation is often written as:

Ev = (L x S)/(10.76D*D) Eq. 2

In this equation, L is in nits, S is in square feet, D is in feet, and Ev is in footcandles.

By applying this functional relationship, a designer can optimize LED channel-letter illumination to produce uniform brightness that is more energy efficient, and longer lasting than most established installations.

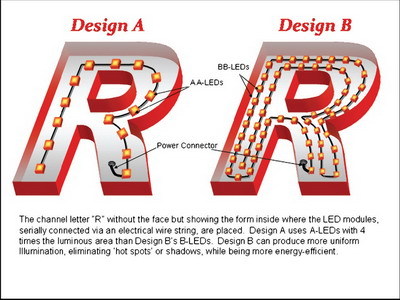

In Design A (Fig. 1), the LED module’s (labeled as “AA”) surface area is 4 a.u. – a.u. being the arbitrary unit of square area. There are 15 discrete, AA-structure LEDs with a total surface area of 60 a.u. In Design B, each LED module’s (labeled “BB”) surface area is 1 a.u., and 62 BB-structure LEDs have a total surface area of 62 a.u.

Distance D is the gap between the LED surface and the channel-letter face, which is the same in both designs. In order to produce equivalent illuminance at the face (assuming only normal angle inci¬dence), Eq. 1 yields:

EvA = (LA x SA)/D*D = EvB = (LB x SB)/(D*D) Eq. 3

where EVA and EVB are the center illuminance at the channel-letter surfaces of the two designs; LA and LB are AA-LED’s and BB-LED’s luminance values and SA and SB are total surface areas of the two designs. Note that SA and SB are 60 a.u. and 62 a.u. respectively. Eq. 3 yields:

LB = (LA x SA)/SB

and hence; SA = 60 a.u. and SB = 62 a.u., LB = LA (0.968), meaning design B’s LED luminance is ~4% less than the AA-lamps. This is a small difference, thus, we can effectively say both LED types have similar luminance.

Note, however, that the BB-LEDs should only produce 25% less luminous flux (lumen output) over a quarter of the area compared to AA-LEDs, to produce the same illu¬mination level. Therefore BB-LEDs can be driven with 25% less current or even lower; this is possible because, at a lower drive current, the efficacies (lumen/watt) are higher. This makes Design B more energy efficient. Additionally, driving with lower current will also increase the lifetime of the BB-LEDs. The same power supply can be used for both designs.

Design B benefits are improved uniform illumination of the sign face and reduced color variation among channel-letter faces. Typically, a sign fabricator inevitably faces an annoying amount of color variation that arises from a more economic color bin that contains a broad range of colors. (Design B’s color variation is substantially reduced, because the greater number of LEDs [for example, 62 BB-LEDs vs. 15 AA-LEDs] provides superior color averaging.)

The exampled calculations ignore the cosine dependence of illuminance as well as the full integration over the channel-letter surface, in order to make straightforward arguments, Nevertheless, design comparisons, here, provide validity on an “average sum,” approximation basis – this trend can be extended to the full-integration case.

I’ve reviewed numerous designs from several companies, where most choose module patterning similar to A, and only a few are like B. Signmakers have also asked me about solutions to the binning problem. Design B should help with this concern.

The above comparison shows Design B as superior. The ideal design would extend the concept, where numerous, minute LEDs would cover the entire surface of the channel letter back, to allow further, reduced lumen output for each LED lamp. Broad-area organic LEDs (OLEDs) fit this description; however, OLED technology is less mature than conventional LEDs.

As president of LED Lighting Technologies, Dr. M. Nisa Khan educates the lighting industry and consumers about LED lighting. She has a bachelor’s degree in physics and mathematics, and master’s and Ph.D. degrees in electrical engineering. Email her at nisa.khan@iem-asset.com

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Projects1 week ago

Projects1 week ago4 of the Most Fun Sign Projects in Years

-

News2 weeks ago

News2 weeks ago2024 Sign Contest Open for Submission

-

How To1 week ago

How To1 week agoMaking the Grade with ADA Signs

-

Real Deal3 days ago

Real Deal3 days agoA Family Sign Company Foists Their Youngest Upon the Business

-

Editor's Note4 days ago

Editor's Note4 days agoThe Joy of Working

-

News3 days ago

News3 days agoWoman Found Living Inside Supermarket Sign

-

Photo Gallery1 day ago

Photo Gallery1 day ago17 Sneak Peeks at the American Sign Museum Main Street Expansion

-

News1 week ago

News1 week agoSign Company Owner Meets Travis Kelce