Digital Printing

GCC

Two hybrid, UV-cure printers that offer varnish-coating, four- and six-color, plus white, ink options

Published

16 years agoon

Lift the hood on numerous, acknowledged UV-cure printers, and you learn that many, including those hailing from Japan, are actually manufactured in China, Taiwan, Korea and other Asian countries. At minimum, such machines surely contain such components. This isn’t surprising, of course, because our world-trade economy promotes outsourcing (and re-badging) to remain competitive. In some instances, the print-engine-producing factories are virtually nameless, relying on their partner’s name recognition to sustain marketshare.

GCC strays from the rule. This innovative company designs, manufactures and distributes numerous products that target the sign, engraving and graphics businesses. The firm prides itself in innovation and has either applied for, or holds, numerous patents. It’s no surprise, then, that GCC distributes products under its own name.

In the United States, GCC is best recognized for its laser-based engraving products, but, after having met with its staff at ISA’s Sign Expo 2008, we’re thinking they’ll soon make even more noise in the wide-format, UV-cure, printer arena. Presently, they have two printer models that address mid-level and large printmaking shops. The print machines’ pricing is competitive, and the print quality looks great. Therefore, if you’re looking for a large-format, UV-cure printer, keep reading to learn more about GCC’s StellarJET line of UV-cure printers.

The StellarJET 183UVK

We’ll start with StellarJET 183UVK, the more affordable choice. Although UV-cure printer prices have fallen year by year, it’s still costly to get into the game. So far, the printer manufacturers that attempted to come in under $50,000 haven’t done well. The 183UVK isn’t in that class – it sells for $72,995 – which settles it into a competitive spot for a quality, hybrid printer.

Where does the printer get its name? The StellarJET 183UVK media width is approximately 72 in. (182.9 cm). The inkjet and UV designation is pretty obvious, but the “K”? If you’ve guessed it relates to the printheads’ manufacturer, Konica (Fig. 1), give yourself a gold star. Put it all together, and you get 183UVK.

AdvertisementThe 183UVK is a sturdy-looking machine. The one key component of any hybrid printer, the table, is notably stout and loaded with substantially sized rollers. With the tables deployed, the machine dimensions are 593⁄4 in. high x 1305⁄8 in. wide x 905⁄16 in. deep. You’ll need a fairly good-sized area for such a printer, so don’t consider it an “office” device. The power requirement is 200-240VAC at 20A, 50/60 Hz.

The printing system

The StellarJET 183UVK has dual, UV-cure lamps guarded with a shutter system that blocks UV light during maintenance operations. The standard printer is a 720-dpi, four-color (CMYK) system, but GCC offers numerous options.

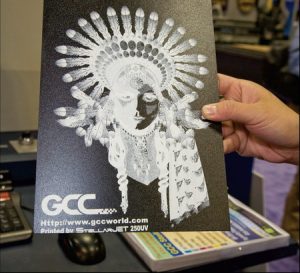

For example, if your shop prints more photorealistic work, such as posters or POP signs, you may choose the light cyan/light magenta ink option that raises an image’s apparent resolution to 1,440 dpi, with smoother tones. Do you produce graphics on clear media or non-white surfaces? No problem. Choose the white-ink option that prints on clear media and black or colored substrates (Fig. 2). Also, you can opt for the varnish coating if you want special effects or to ensure scratch resistance without lamination. As you can see, the printer is versatile.

Each ink color has a continuously monitored, 2-liter, main tank that should keep printing for quite some time. Secondary tanks reside in the carriage assembly. Use these as the primary source, and you can add ink to the 2-liter main tanks on the fly.

Advertisement

Media handling

A hybrid, UV-cure printer, such as the StellarJET 183UVK, can print on either flexible or rigid media. In practice, it accepts such rigid sign substrates as foamboard, metal and plastic media, or flexible banner media and adhesive-back vinyl.

For imaging on rigid media, you fold out the two, roller-table “wings” located on the printer’s opposite ends. There, seven rows of evenly spaced rollers provide a smooth, rolling surface for the media. You can order an optional table extension, for use with extra-long media.

Maintaining rigid-media alignment during the print process can be a challenge on roller tables – a miniscule misfeed can ruin media. Consequently, GCC designed and incorporated its Lucid-Guide technology, a system that comprises a media-guide piece, vacuum system and media bar (Fig. 3) to ensure everything feeds straight and true.

The 183UVK can handle media thicknesses up to an inch. Here, GCC has developed another bit of magic, the Lucid-Focus. This technology utilizes a built-in calibration system, and a simple gauge informs the operator of the optimized media height. Less fiddling means more productivity.

So you’ve printed all those foamboards, and the banners wait in queue. No problem. Don’t detach the roller tables; just fold them down against the printer (Fig. 4). Now load the flexible media, and let the automatic-feed system ensure the materials properly feed through the platen. The 11-zone, operator-controlled, vacuum-assisted platen system also helps keep flexible media aligned. GCC appropriately offers an optional power-assisted, take-up system for long jobs.

AdvertisementSpeed and print quality

The 183UVK isn’t the fastest printer you’ve seen, but it clocks respectable times. In draft mode, it will produce 319 sq. ft./hr. The production mode is approximately half as fast at 162 sq. ft./hr., and, if you’re producing high-quality, photographic-type work, you’ll see the speed cut to 81 sq. ft./hr. The images we saw were quite good and well-saturated with ink.

Interface and software

The 183UVK comes with a 10/100/1000-bit Ethernet connection. With gigabit Ethernet becoming today’s “norm,” it’s nice to see a device take advantage of such speed. An operator’s console provides status and maintenance information.

A Christmas-tree-like indicator signals when the printer is running, paused or stopped. Mounted high on the printer, it can be read from across the shop. Onyx Graphics’ (Salt Lake City) ProductionHouse or PosterShop software can drive the printer.

The larger, StellarJET 250UV

The StellarJET 250UV-cure printer builds on the 183UVK’s innovations. However, it’s a genuine, grand-format printer designed as an industrial workhorse. Additionally, many 183UVK options are standard on the 250UV. A generous, service-station area eases cleaning, servicing and purging tasks. Also, you can easily access, adjust and service the module-type heads.

Specifications

Although the 183UVK has an open, almost skeletal, look when the roller tables are deployed, the 250UV is fully enclosed. It’s 26 in. wider than the 183UVK and 30 in. shorter, with the tables extended. The overall dimensions are 1947⁄16 in. wide x 657⁄8 in. high x 585⁄16 in. deep; it weighs 3,087 lbs.

The printing system

The 250UV-cure uses Xaar heads with a 360 x 360-dpi printing resolution. It can produce 720 x 720-dpi apparent resolution when printing in high-quality modes. The printer can handle media up to 983⁄16 in. wide, which means it can process a 4 x 8-ft. sheet of material loaded longitudinally. Standard on the 250UV are the optional light primary colors and white ink.

The larger printer’s speed is slightly faster than its sibling’s. Draft-mode print speed is 451 sq. ft./hr. The normal-quality mode is 226.8 sq. ft./hr., although its quality-production mode runs at 167.4 sq. ft./hr. The highest-quality mode is a respectable 84.2 sq. ft./hr. The images look good, and GCC provided numerous, exotic media for printing and viewing, including tiles, for example.

Media handling

Examine the printer’s specifications, and you might guess the 250UV is a roll-to-roll printer, not a hybrid. However, GCC classifies the 250UV as a hybrid and has applied numerous technical innovations for rigid-media handling. Raise the front cover, and you’re presented with a wide belt and a fairly ample surface to feed media up to 2 in. thick.

The printer also incorporates an Auto Media Calibration system, which gauges, and automatically adjusts, the needed media/printhead gap. Flexible media conforms to a roll-to-roll system that’s built into the printer’s base. The same wide platen ensures it tracks correctly.

Final touches

Interestingly, the 250UV printer has a 10/100 Ethernet system-interface connection, but logic says this system will soon upgrade, to match the 183UVK’s gigabit capabilities. The printer comes with an integrated, heavy-duty operator’s console.

All in all, we think the $175,000 250UV is a great machine – it has good speeds, nice print quality, and the expected convenience and flexibility of UV-cure printing. It features bullet-proof design and construction that indicates it can satisfy a large shop’s demands.

Conclusion

The 183UVK looks like a great choice for established, medium-sized signshops entering the UV-cure, digital-printing field. If you need a heavy hitter, the 250UV may be just what you need. These machines have excellent specifications and appear well built. Additionally, GCC, established in 1989, has a U.S. presence. If you’re in the market for a UV-cure printer, look at GCC. (To see a video, search YouTube for StellarJet 183UVK.)

Key Information

GCC America Inc.

323 Paseo Tesoro

Walnut, CA 91789

(909) 718-0248

www.GCCWorld.com

Company Profile: Founded in 1989, GCC is a forefront, global manufacturer of equipment for the visual-tech industries; its products include equipment for the signage, textile, trophy, award, packaging and large-format printing industries.

Contact: Jeff Lee, sales and marketing manager, sales@gccamerica.com.

At a Glance: The StellarJet 183UVK is a 72-in. wide, hybrid (flatbed and roll-to-roll) printer that applies CMYK UV-cure inks. Its options include varnish coating, white ink and a six-color (CMYK plus light cyan/magenta) ink system.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times1 week ago

Ask Signs of the Times1 week agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo6 days ago

Paula Fargo6 days ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal3 days ago

Real Deal3 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks2 weeks ago

Benchmarks2 weeks ago6 Sports Venue Signs Deserving a Standing Ovation

-

Photo Gallery6 days ago

Photo Gallery6 days ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers