RED IS RED, blue is blue and green is green, right? When you show your client a proof of their new sign, you may quickly find that what you thought was a pale blue isn’t even close to their expectations. So, you go back and tweak the design and the client says it’s close, but not quite there. Well, you can see where this is going… Before digital printing, color management was simple. You took a set of swatch books with you and had the customer pick the colors they wanted. The vinyl was consistent in color so there were no surprises. Unfortunately, there are no simple solutions for digital printing, but there are tools and knowledge to make things more consistent.

When you create a sign in design software, you can be working with two different types of artwork. Text, logos and shapes are basically line or vector graphics that you will assign colors from swatch menus. Often you will also include photographic images in the design, as well (think of a menu board with a photo of the food). Each element, vector and photographic (raster), is dealt with in different ways. Let’s take a look at both situations and how color management can help.

Advertisement

Achieving accurate color output consistently requires a combination of OEM and RIP profiles fine-tuned by a colorimeter or spectrophotometer.

A common problem with both types of graphics is that the entire design goes through a series of transformations as it is processed. The designer is working with a monitor that produces color in a red, green and blue (RGB) color space. This color space is quite large and can produce a huge quantity of colors. The digital photograph also uses an RGB color space, as will the swatch menus displayed on the monitor.

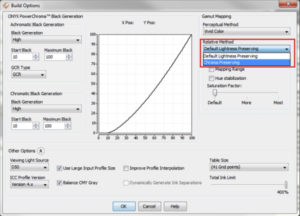

The physical print is typically produced using cyan, magenta, yellow and black (CMYK) inks. Yes, light, metallic and spot-color inks can further complicate things. The color gamut of the inks is much smaller than the monitor and will result in the print software compressing the colors, leading to color approximation that results in angry customers.

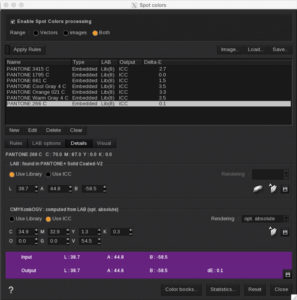

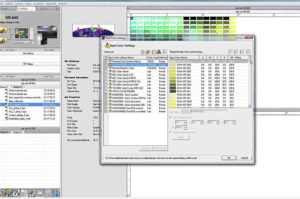

Color management tools can greatly alleviate these problems. Colorimeters can be used to calibrate monitors to ensure the colors are consistent. Next you need to have specific ICC profiles for the inks, printing resolution and media selected in the RIP. Media manufacturers will typically supply profiles on their websites. Be aware that these are general profiles and still may not provide the accuracy you expect. For the best results, use a spectrophotometer and create your own profiles or edit existing ones. Most RIPs and design software can supply this capability either as part of the main application or as an option. Also, be aware that sublimation printing can present additional issues. Images printed on transfer paper, for example, will look flat and dull until transferred to the fabric. Without a good color management system, you would be relying on guesswork.

So, where do you even begin? Check the websites of your RIP and design software manufacturers. Many of them offer videos covering how their color management systems work. You do need color management hardware if you want to edit and create your own custom profiles. This may sound like a lot of expense and trouble, but once you have established a system, color surprises will begin to disappear.

PHOTO GALLERY (6 IMAGES)

Advertisement

Photo Gallery1 week ago

Photo Gallery1 week ago

Ask Signs of the Times1 week ago

Ask Signs of the Times1 week ago

Paula Fargo6 days ago

Paula Fargo6 days ago

Real Deal3 days ago

Real Deal3 days ago

Benchmarks2 weeks ago

Benchmarks2 weeks ago

Photo Gallery6 days ago

Photo Gallery6 days ago

Women in Signs1 week ago

Women in Signs1 week ago

Women in Signs1 week ago

Women in Signs1 week ago