Manfred Didier and his business partner, Marcus Goebels, founded Timber Signs in Cologne, Germany as a part-time enterprise in 1998 – at the time, Didier was a master electrician, and Goebels constructed cabinets. According to Didier, they spent their first three years attending workshops and training sessions, and used trial and error to determine ideal materials and production methods.

“Our earliest signs were made from sandblasted redwood,” he said. “The German word for such signage, “holzschilder”, doesn’t really sound catchy, so we turned to English and called it Timber Signs.”

In 2001, after having purchased a Gerber Sabre 408 CNC router, they ramped up their signmaking business to full-time. Didier said much initial work involved residential signs and name plaques for private customers. Eventually, the shop’s repertoire grew to include hotel, restaurant and resort signage; as their client list expanded, their growth dictated a move into a new facility in Ofterschwang, a small Bavarian town in the foothills of the German Alps.

Didier and Goebels have attended numerous U.S. Letterhead events (the Letterheads are a loose affiliation of signmakers who practice traditional signmaking methods), so they’ve noticed several similarities and differences between each nation’s sign trades.

“Signs in Germany tend to be a little more plain, flat and technical,” Didier said. “There’s more emphasis on sans-serif fonts and basic colors with minimal artwork. Also, because businesses and office spaces change hands less in Germany than the U.S., our signs are usually expected to last longer. However, because few shops work with HDU and wood signage here, we stand out in Germany. One challenge is that our laws forbid advertising signage for certain professions. Unfortunately, we’ve never had the opportunity to build signs for a doctor, lawyer or dentist.”

He continued, “Customers are the same everywhere. They take forever to make a decision, but when they do, they scream they want it yesterday. And, we sometimes have issues of sloppy, low-resolution art from their nephews that they demand we use.”

Advertisement

Didier said Timber Signs earns most of its work from hotel- and restaurant-industry tradeshows; they’ve attended approximately 50 in Germany, Austria and Italy. In contrast to a common American practice, Didier said referrals are few: “Our customers are very satisfied, and they don’t want their competitors to know they have a Timber Signs sign.”

For most of their projects, clients submit vector files, which are often prepared by graphic designers or marketing agencies. To prepare them for production, Didier uses an online service called evectorize.com, which creates a high-quality file that will maintain consistently high resolution when subjected to any level of magnification. When it creates custom graphics, Timber Signs begins with pencil-and-paper sketches that are scanned and refined using Gerber’s ArtPath or Omega software, or Delcam’s ArtCAM software for jobs that require CNC routing.

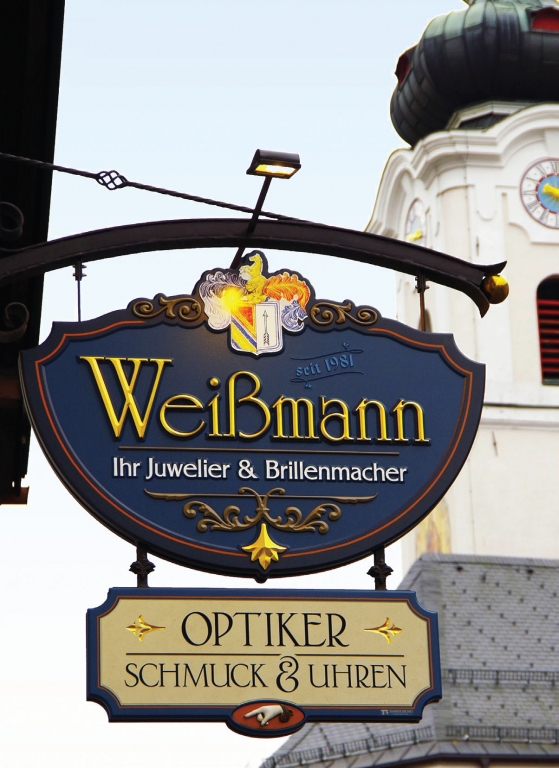

Thankfully, jewelers and optometrists can promote their trade through signage; Timber Signs built a bracket-mounted sign that promotes a main-floor jeweler and a basement optometrist. Because Timber Signs installs few of the signs it fabricates, Didier creates very detailed renderings that show customers how to align sign components for proper installation.

He said, “The storefront, which houses both establishments, is located in a village between the Autobahn and several popular tourist destinations, so it had to be seen from far away. I thought a bracket sign would be most effective.”

The 4 x 4-ft. WeiBmann (a German alternate spelling for Weissman) sign comprises 18-lb. Corafoam® HDU fabricated on the shop’s Sabre router. Fine details, such as the downward-pointing hand, were deftly crafted with Pfeil chisels. To decorate the placard, they printed the shield on a Gerber EDGE® 2 thermal-transfer printer, and painted the pinstripes with Mack brushes and acrylic paint. After a slow-size application, Didier gilded the name on the panel with 23.75k goldleaf.

Timber Signs also fabricated a handsome sign for Landhaus (“country house” in German) Schlosser, a Bavarian brewpub. A regional brewer, Alpirsbacher Klosterbrau, sponsored the sign and had its logo printed and applied to the secondary panel. The sign was fabricated similarly to the WeiBmann sign, and the customer handled its installation.

Advertisement

In both cases, the HDU signs were applied to a ½-in.-thick, plywood backing layer, and a local blacksmith fabricated the galvanized-steel frame and the wrought-iron scrolls that encase the signs.

Photo Gallery1 week ago

Photo Gallery1 week ago

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks ago

Paula Fargo7 days ago

Paula Fargo7 days ago

Real Deal4 days ago

Real Deal4 days ago

Benchmarks2 weeks ago

Benchmarks2 weeks ago

Photo Gallery7 days ago

Photo Gallery7 days ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago