Automated baggage information display systems (BIDS) and automated flight information display systems (FIDS) are those conspicuous monitors and screens that guide airline passengers to their luggage and respective gates. Thousands of people rely on these electronic signs daily to catch their flights and reunite with their luggage. The numerous technologies include light-emitting diodes (LEDs), cathode-ray tubes (CRTs, or television screens"), liquid-crystal displays (LCDs), plasma displays (electroluminescent) and magnetic-actuated disks (often seen at bus and train stations, and more popular in Europe). Manual systems with lettering strips and numerals are still in use in many airports. Systems automatically update their pre-programmed schedule throughout the day. The Americans with Disabilities Act (ADA) also mandates visible and audible paging-information systems. Supplying signs requires a business scope far beyond the average sign company’s capabilities. Local and national sign companies and large airport contractors bid on the total installation packages. A local sign company can qualify for the bid list and receive a "request for bid/proposal" (RFB/RFP). The sign-installation contractor then requests a written "scope of work" from each contractor (usually up to 20). After a bid is prepared and bid bonds are secure, there’s a public bid opening. At this stage, it’s still doubtful that a local sign company will win the contract. The sign company can then contact the "winner" and offer its installation services. A local sign company near a new or renovated large airport project can add several hundred thousand dollars to their annual sales with BIDS and FIDS. Several years ago, at Terminal 4 at Phoenix International Airport, Las Vegas, NV-based Young Electric Sign Co. (YESCO) was the third-lowest bidder. The lowest was a general contractor. And the sign company bidding second lowest provided installation services to the general contractor. Often, the low bid fails, and a reputable sign company picks up the contract and performs a miracle on overtime. Typically, this involves a 15,000-sign project that requires three to four weeks to prepare the estimate. A bonded local sign company once bid a half-million dollars because that was the limit of its license. As it turned out, the shop missed the bid by $1 million and tried desperately to get its $50,000 cash bond refunded. Don’t forget that cabling the wiring for signs involves payments of hundreds of thousands of dollars. At Denver International Airport, I attended three pre-bid meetings over a one-year period, each hosted by a different designer-architect or contractor. The airport opened one year behind schedule, and cost overruns approached $2 billion. A large, experienced sign company can anticipate such a calamity and choose not to bid. Companies bid on installation of the systems. There have been large packages, including the BIDS and/or FIDS products installed. Both the sign and general contractors may bid in competition, and the sign contractor may lose the supplier contract and still win the installation. Should the sign contractor not bid on the package, they usually contacts the announced winner of the bid to offer installation services.

Photo Gallery1 week ago

Photo Gallery1 week ago

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks ago

Paula Fargo1 week ago

Paula Fargo1 week ago

Real Deal4 days ago

Real Deal4 days ago

Photo Gallery1 week ago

Photo Gallery1 week ago

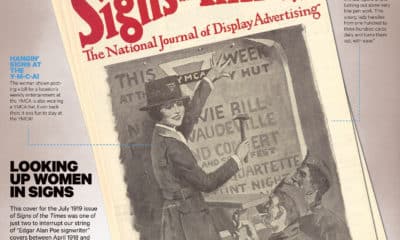

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago

Signs of the Times1 week ago

Signs of the Times1 week ago