Electric Signs

Making a Memorable Marquee

Wagner Signs embellishes a South Bend, IN, landmark.

Published

18 years agoon

The Wagner Electric Sign Co. has spent more than 20 years perfecting the restoration and redevelopment of historical theatre marquees as one of our market niches. This difficult journey has included many lessons along the way. We take pride in our shop's role in reinforcing a building's rich history. And, we don't take such challenges lightly.

A company history

Our story begins in 1954, when Carl W. Wagner Sr. founded the company. He was a gifted commercial signpainter — a brush in his hands meant a work of art was only a few strokes away. Soon, his son, Carl W. Wagner Jr., chose to pursue electric-sign design and fabrication once he assumed company leadership.

In 1980, the company renovated the marquees for downtown Cleveland's State and Ohio Theatres, which quickly generated a similar opportunity in Pittsburgh. Con-sequently, Wagner gained a nationwide reputation. Recently, we completed work for San Jose's California Theatre and St. Louis' Fabulous Fox Theatre. In this space, I'll recount Wagner's design, fabrication and installation of a new marquee for South Bend, IN's Morris Performing Arts Center.

AdvertisementCreating a masterpiece

The Morris Performing Arts Center owns a colorful history. Built in 1921, the 2,560-seat facility has hosted generations of famous entertainers, from the Andrews Sisters to B.B. King to Jerry Seinfeld. Dennis Andres, the Morris' executive director, said the center received an exhaustive $17 million overhaul, prior to its 2000 reopening, that entailed replicating the paint, goldleaf and plaster the center featured at its inception.

However, Andres and other Morris officials wanted to upgrade the marquee and decided to pursue the project this year. Previously, the very pedestrian, single-faced sign featured unimaginative, black letters. We were given full autonomy to design a marquee that honored the building's décor and nostalgic appearance, yet added the appeal of state-of-the-art technology.

After having completed very detailed site surveys – which determined the building's architectural elements, condition, materials, dimensions and structural integrity — we began developing conceptual drawings. Accuracy was vital because of numerous impending approvals – in addition to the center's officials and our team, the city and county zoning boards, the local historical society, and all parties that contributed to the center's refurbishing, had to give their blessing.

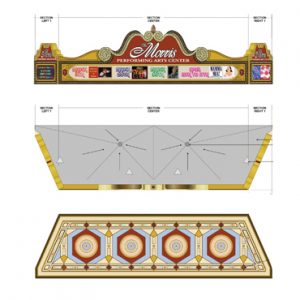

Following a consensus for a single marquee, Wagner developed an exacting, 3-D computer model of the 55-ft.-long sign, which would project 15 ft. over the sidewalk below. This model allowed the client to move the marquee around, zoom in and out, and simulate different ambient-light conditions.

AdvertisementWe built the Morris Center's marquee where a large canopy had previously been installed. Typically, when the marquee is smaller than what it's replacing, we assume that the building can safely handle the load. However, an exploratory demolition indicated the old marquee had been set on a masonry ledge. We didn't find any steel inside the brick columns, so the existing masonry needed to be replaced. The city's engineers approved using an epoxy system to install bolts into the new masonry.

Next, a certified welder added extensions to the support rods that had been cut out when the original marquee was removed. We completed this work while carefully working around the original terra cottta on the building's façade. When we began working, we couldn't locate drainage pipes within the wall to dispatch water from the marquee's roof. However, as we proceeded, we found them and merged the pipes with the roof's drainage system.

A marquee encompasses all aspects of an involved sign/construction project that typically takes up to 10 months, from the budgetary decisionmaking through the final installation. This typically follows a two- to five-year sales process. Accurately projecting costs, and staying within the allocated budget, remains the single greatest challenge.

Concept and creation

After we received conceptual approvals, we began producing shop drawings using Adobe Illustrator®. These detailed and complex drawings require weeks and even months to generate.

Our design department uses the site-survey data to create accurate, practical renderings. We usually make many modifications during this phase, such as aesthetic alterations to the colors and décor, structural changes and upgrades, such as replacing static letters to LED message boards.

AdvertisementWe began the fabrication phase by building the complete, steel, support structure. Next, we fabricated the three aluminum sides and the fiberglass architectural elements. Concurrently, we fabricated the ceiling detail and sized the steel decking for the rubberized roof that was installed as a top layer. These are fitted together to allow for adjustments.

Then, we disassembled the pieces and sent them to the paint department for decoration with Matthews acrylic-polyurethane paint. We paint our signs in a 20-ft.-tall, 24 40-ft. room that allows ample workspace. Once these sections are decorated, we wire and test them. We determine the voltage early in the design process and wire according to the site's capacity.

This new marquee sports a fully automated and customized flashing system with solid-state flashers. These employ either onboard controllers that manage preprogrammed systems, or a DMX-512 controller in the theater's office, which may direct the action. This allows a long list of different flashing, spelling and chasing sequences. We use long-life, fluorescent lamps instead of traditional, incandescent lamps. These 2,000, fluorescent lamps offer longer service and substantial energy savings.

We used flash-capable, S14 fluorescent lamps, which are rated for 25,000 hours of service – much longer than the anticipated lifespan of incandescent lamps, which typically last 5,000 to 8,000 hours. And, S14s consume 2W of energy versus incandescents, which consume 11W. Multiplied by 2,000, that amounts to 18,000W. Such substantial energy and component savings made this an easy decision.

The marquee's colors were inspired by the aged terra cotta that decorates the building's entire exterior façade. The marquee's three sides employ Daktronics' ProStar® and Galaxy® full-color, LED video-boards. The LED boards are wrapped on the ends with custom, decorative fiberglass pieces made in Wagner's plant to provide a more tailored look.

The ceiling detail is one of the most intricate we've fabricated. It has many difficult angles as well as many different levels and planes. For added effect, we installed three searchlights atop the marquee for use at highly publicized events.

We partnered with John Yarger and his very professional shop, North American Signs Inc. (South Bend), to complete the installation. The installation process presented many challenges, but North American and other subcontractors (roofing, plumbing, and electrical) worked quite well together and moved towards a common goal of completing the project on time.

Unlike most other sign types, marquees don't usually include maintenance agreements. Most theatre owners employ an inhouse, full-time maintenance crew, and, to save money, owners usually let their own staff handle sign maintenance.

We find historic-theatre managers increasingly embrace newer technology to enhance the patrons' experience. They adhere to the venue's historic context, yet they utilize the sign industry's state-of-the-art capabilities.

The Morris Performing Arts Center's marquee, and the many similar ones Wagner has fabricated, are truly works of art accomplished by many hands as a labor of love. However, Anders offered the greatest testament to its effectiveness.

"We booked a comparable number of shows for the first half of this year versus last year, yet our ticket sales have increased by 60%," he enthused. "Being situated on a street where 50,000 cars drive by on an average day, an effective marquee offers a powerful advertising tool."

More about Mark

Mark Wagner is president of Elyria, OH-based Wagner Electric Sign Co., which is located approximately 25 minutes from Cleveland. A graduate of Lynchburg, VA-based Liberty University's business school, he's the third generation of his family to operate the company (his brother, Darryl, is its vice president). At the beginning of 2005, he purchased the company from their father, Carl Wagner Jr.

According to Wagner, the company has successfully teamed with historical preservation groups, design and architectural firms, civic organizations and private-ownership groups to assist in the manufacture and restoration process of historical theatre marquees nationwide.

More about North American Signs Inc.

The late Maurice P. Yarger founded the South Bend, IN-based company as South Bend Neon in 1934. The firm initially specialized in neon signs for local car dealerships and retail shops. Later, the company began fabricating fluorescent-lit, plastic-faced, cabinet signs.

During the late '70s, the company shifted its focus to fabricating sign programs for regional and national companies, such as Barnes & Noble Booksellers and Red Roof Inn. Today, the company emphasizes LED-illuminated signs. North American Signs Inc. has grown into a 13-acre plant, and Yarger's sons, Tom and Noel Yarger, are still actively involved in its operations, and his grandson, John Maurice Yarger, now runs the company.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

American Sign Museum Names New Executive Director

3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

Graphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery2 days ago

Photo Gallery2 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times4 days ago

Ask Signs of the Times4 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks6 days ago

Benchmarks6 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoWhy We Still Need the Women in Signs Award

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Megan Bradley

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More