Roland DGA Corporation’s new METAZA MPX-60 photo-impact printer proves that you don’t need big equipment to make big money.

So, what can the MPX-60 do for your shop? Most of us continually seek new sources of revenue and new products to offer our customers. Offering personalized items is an obvious alternative.

Many shops already offer screenprinting and/or embroidery services to leverage an existing client base and existing artwork. Engraving is another profitable niche.

The MPX-60 is an affordable way to expand your business offerings quickly — plus, the machine doesn’t require a major learning curve.

With the MPX-60, you can imprint photos, text, logos and more onto acrylic, gold, silver, platinum, brass, copper aluminum, metallic labels and stainless steel using an impact-marking technology.

Impact printing has been around for ages. However, this printer incorporates a diamond-tipped stylus that strikes the marking surface with a variable force. An image’s darker parts require a harder force; its lighter parts require a softer force. Whether the original is a color or black-and-white image, the MPX-60 handles the color gradation or shades of gray remarkably well. The inkless system permanently marks flat surfaces without removing a layer of material. In other words, it’s a metal printer. You can achieve engraving’s benefits and more without the mess of an engraving machine.

Specifications and setup

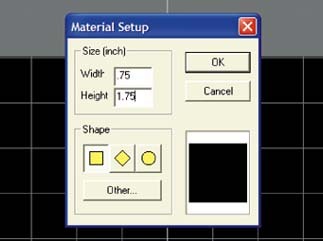

The Metaza MPX-60 is a 256/212-dpi impact printer with a maximum printing area of 31/8 x 31/8 in. The loadable material size is 31/2 x 31/2 x 3/4 in. The maximum printing speed is up to 9/16 in. per second. Its external dimensions are 95/16 in. wide x 1211/15 in. deep x 81/2 in. high, and it weighs 15 lbs. It’s connected via USB 1.1, and it includes an AC adapter, a power cord, a CD-ROM (for the Dr. METAZA2 driver and imaging software), a leveler, marking material for testing, a Phillips screwdriver and a compact user’s manual.

Installing the printer is quite easy. Take the machine out of the box; remove the screw using the supplied Phillips screwdriver; and install the power supply. Keep the printer’s power turned off. Set the printer on a level surface — move the printer by gripping its bottom only. For best results, make sure the area has minimal dust and 35 to 85% humidity, in a temperature range between 50

News4 days ago

News4 days ago

Projects2 weeks ago

Projects2 weeks ago

News2 weeks ago

News2 weeks ago

How To1 week ago

How To1 week ago

Real Deal4 days ago

Real Deal4 days ago

Editor's Note5 days ago

Editor's Note5 days ago

Photo Gallery2 days ago

Photo Gallery2 days ago

Product Buying + Technology6 days ago

Product Buying + Technology6 days ago