IS THERE ANY signshop that doesn’t sell banners? Maybe some specialty shops without printers don’t, but otherwise, banners are a bread-and-butter product for most shops. In the simplest case, blank, pre-grommeted, polyester banners can be purchased in practically any size and even various colors. To these a shop can apply cut-vinyl letters and voilá, you have a nice product that can be used both indoors and out.

Of course, this is the 21st century and what was fine for so many folks for so many years is now blasé. So, how do we spice things up? Full-color images, logos and backgrounds, of course. If you have virtually any type of digital printer, then this can seem easy. Get customer approval for the design, load a roll of media and print. What could go wrong?

Hopefully you found out where the customer is going to hang the banner. If it is for indoor use, then you won’t need to use a heavyweight material. Banner materials range from 13 to 18 oz. for vinyl/polyester media. Indoor and/or short-term applications can get by with lighter media. For long-term, outdoor banners that may be subjected to harsh environments, heavier media is required. You also want to ensure that the media you choose will work with your printer. Some media is designed for aqueous inks exclusively, so eco-solvents will not work.

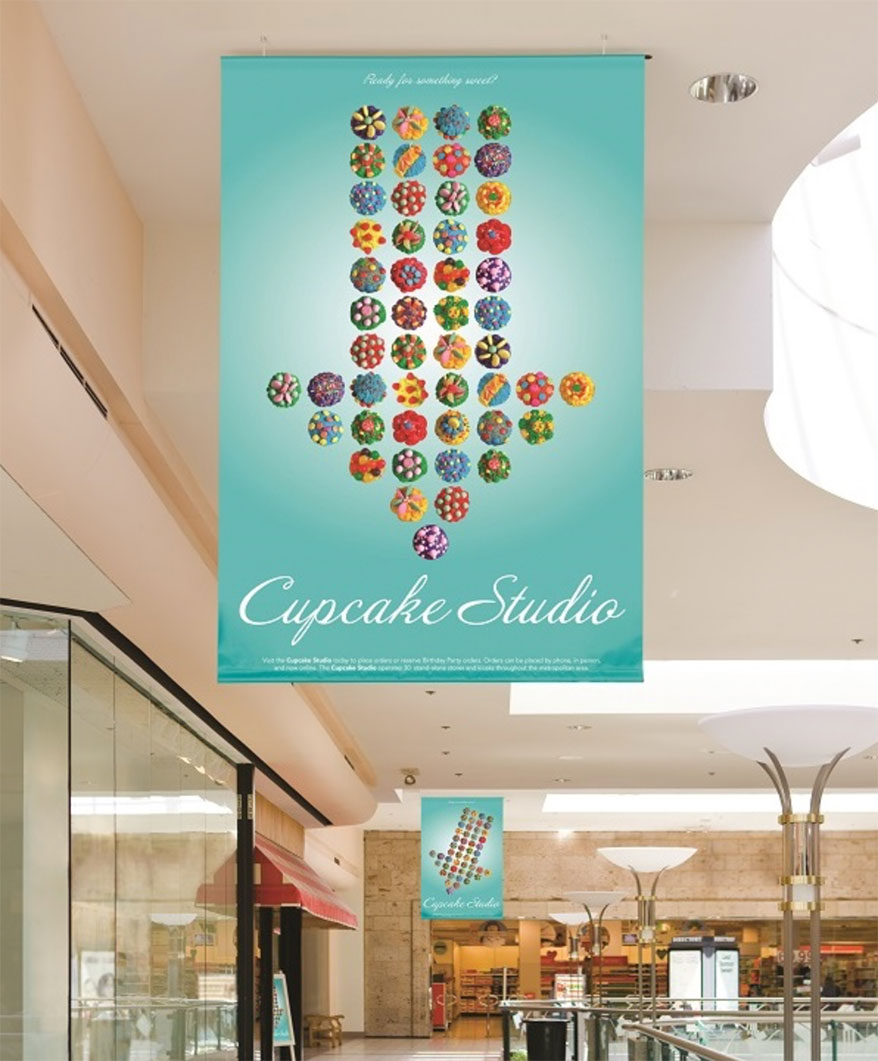

Other considerations primarily have to do with placement. Some banners will be viewed up-close, such as on a sidewalk or in a store. In those cases you may want a smooth finish that will not show the texture of a scrim or mesh banner. In many cases the customer may want a graphic that is displayed on both sides of the banner. For those you will want two-sided media that has an opaque blockout layer in the middle to prevent one side from ghosting through the other in strong light.

Finishing school

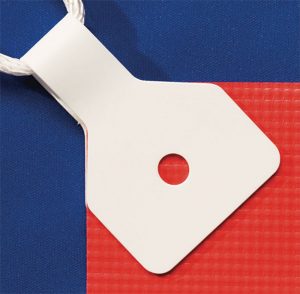

Now that you have the display environment ironed out, you need to figure out how to finish the job. Banners are typically mounted either with grommets or pole pockets. With grommets, the customer will typically use rope to hang the banner. Pole pockets are normally used with vertical-mounting systems and do not use grommets or rope. Whichever way, you have to hem the edges to either create the pocket or to ensure the media won’t tear from the weight of the banner or any wind.

The two most popular methods of hemming a banner are to use a very strong, two-sided banner tape or to use a hem-welder that will literally bond the vinyl/polyester media together with heat. The welding method requires a machine, but it handles the job very quickly. Tape can be applied by hand, simply eyeballing its application, but there are also some taping “systems” that make the job easier. The pole-pocket banners are finished when you complete this step.

Advertisement

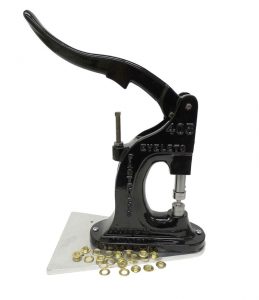

If you need grommets, then the best way to go is to use a grommeting machine. These range from very simple devices that involve the use of a hammer (not advised) up to fully automatic machines that can handle the process in seconds. Some good machines are not automatic, but they accomplish piercing the hem and tightly riveting the grommet for a reasonable amount of money. Other solutions use an adhesive system that doesn’t require a machine. If you only make a few banners a month, then this may work for you.

So there you have it. Banners are truly a fundamental offering in a signshop. While we focused mainly on vinyl/polyester banners, other fabrics are beginning to emerge as well. They offer strength with less weight but require a dye sub printer and the appropriate finishing equipment. With the right materials and the right tools to finish the job, you can make banners an integral product of your shop.

PHOTO GALLERY ( 6 IMAGES)

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery3 days ago

Photo Gallery3 days ago

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery5 hours ago

Photo Gallery5 hours ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago