LED in New Directions

You know you can make more than illuminated signs, right?

Published

2 years agoon

One of the cool things about signs is the sheer variation. A sign company could (in theory) never make the same sign twice. In addition, there are no limits. Some have taken the principles of illuminated signs and applied them to unique lighting projects. Following are three sign companies that demonstrated their creativity with LED lighting.

Ion Art fabricated and installed these LED light poles in North Austin’s new Fontaine Plaza.

OUTDOOR LIGHT POLES

The decline of malls across America has left cities and commercial property owners with decisions to make. Some of the more interesting adaptive reuses have been the creation of mixed-use buildings, often aimed at attracting younger audiences as a space to live, work and play. To a great extent, that’s exactly what occurred recently in Austin, TX.

Austin Community College (ACC) worked with local Redleaf Properties to redevelop the old Highland Shopping Mall into a new mixed-use project in North Austin. The Highland Mall Redevelopment project includes a new college campus for ACC and residential and retail components mixed with new parks and trails. The Fontaine Plaza portion of the property serves as the entry gateway for the new development surrounding ACC’s Highland Campus.

Redleaf Properties hired Austin-based architectural landscape firm dwg. to design the area. The two then met with local sign company Ion Art, led by Project Manager Mónica Boulton, in April 2018. “In November of that year we produced two [LED light pole] prototypes that allowed us to test the LEDs and their mounting method, determine the powder-coat color on the poles, and choose the candy-coat color and application method for the acrylic rods,” she recalls. The installation was to be light poles only, no signs. After, followed a hiatus for about a year…

…With a restart in September 2019, Boulton says. “Everything related to this project was custom-made. It was our first time doing a job like this.” The fabrication of the acrylic rods in particular required a lengthy trial and error phase. “We needed to have precise measurements to mill grooves and holes for screws that were located at the bottom of the rod,” she says. “Another time-consuming task was soldering all of the electrical connections since all of the cables were custom-made.”

Ion Art used a bandsaw to cut the steel pipes for the poles, a laser to cut the steel base plates and also painted the candy color on the acrylic rods. They partnered with several subcontractors to complete other aspects of the job: A machinist milled the acrylic rods, a powder-coating company coated the poles, a local company hot-dip galvanized the base plates, a concrete expert did the concrete footings and trenching, and a programmer created light “shows” to be displayed at different times of the day.

The shop’s fab team fitted each light pole with an individually addressable Gantom DMX Spot white 4W LED floodlight, designed to run on Mean Well LPV-60-24 (60W/24V) power supplies, and programmed via a Pharos controller.

Trenching, installing the conduit and wiring the 73 locations comprised the toughest work. “When you are looking at the light poles on the plaza, it’s hard to imagine the complex underground cabling system,” Boulton says. “It sort of equates to a city that has a subway system.” The 18- to 20-ft.-tall poles were a challenge to install because Ion Art couldn’t use a lift or crane to set them in place. Four installers using ladders and a long pipe were needed to push each light pole into its location.

In 2021, the Texas chapter of the American Society of Landscape Architects Design Awards program recognized the park landscape design, with dwg. receiving the award for designing a gateway park that’s a prime example of parking lots to parks. “We’re proud to have participated in one facet of the park’s success!” Boulton says.

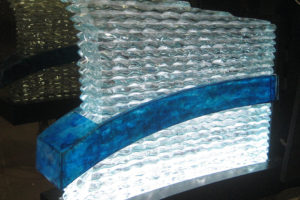

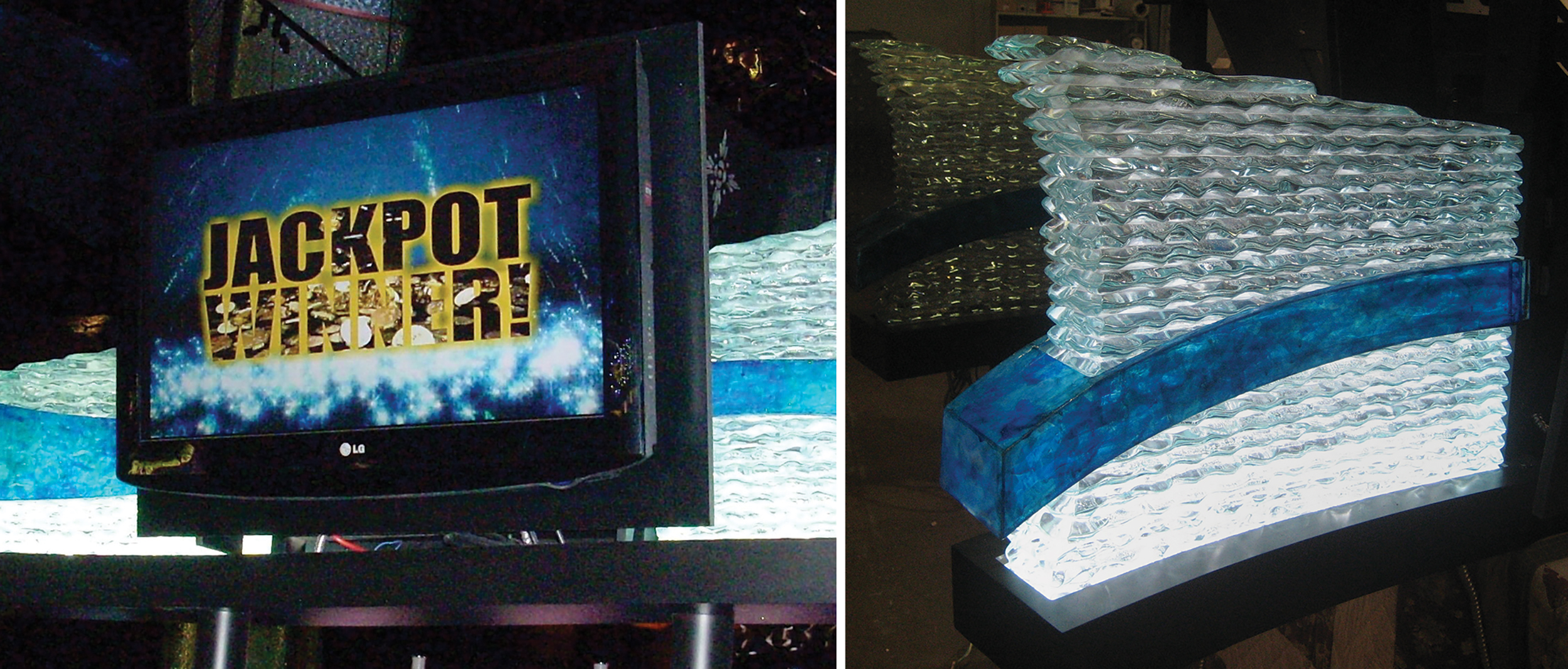

ARTfx created the “Ice Block” light fixture above for the Mohegan Sun casino and resort.

INDOOR LIGHT FIXTURES

It’s no surprise that one of the companies we’re featuring is ARTfx (Bloomfield, CT). Consistent winners in Signs of the Times’ Annual Sign Contest (See ST, September 2021, for most recent), they created interesting, custom light fixtures for two companies.

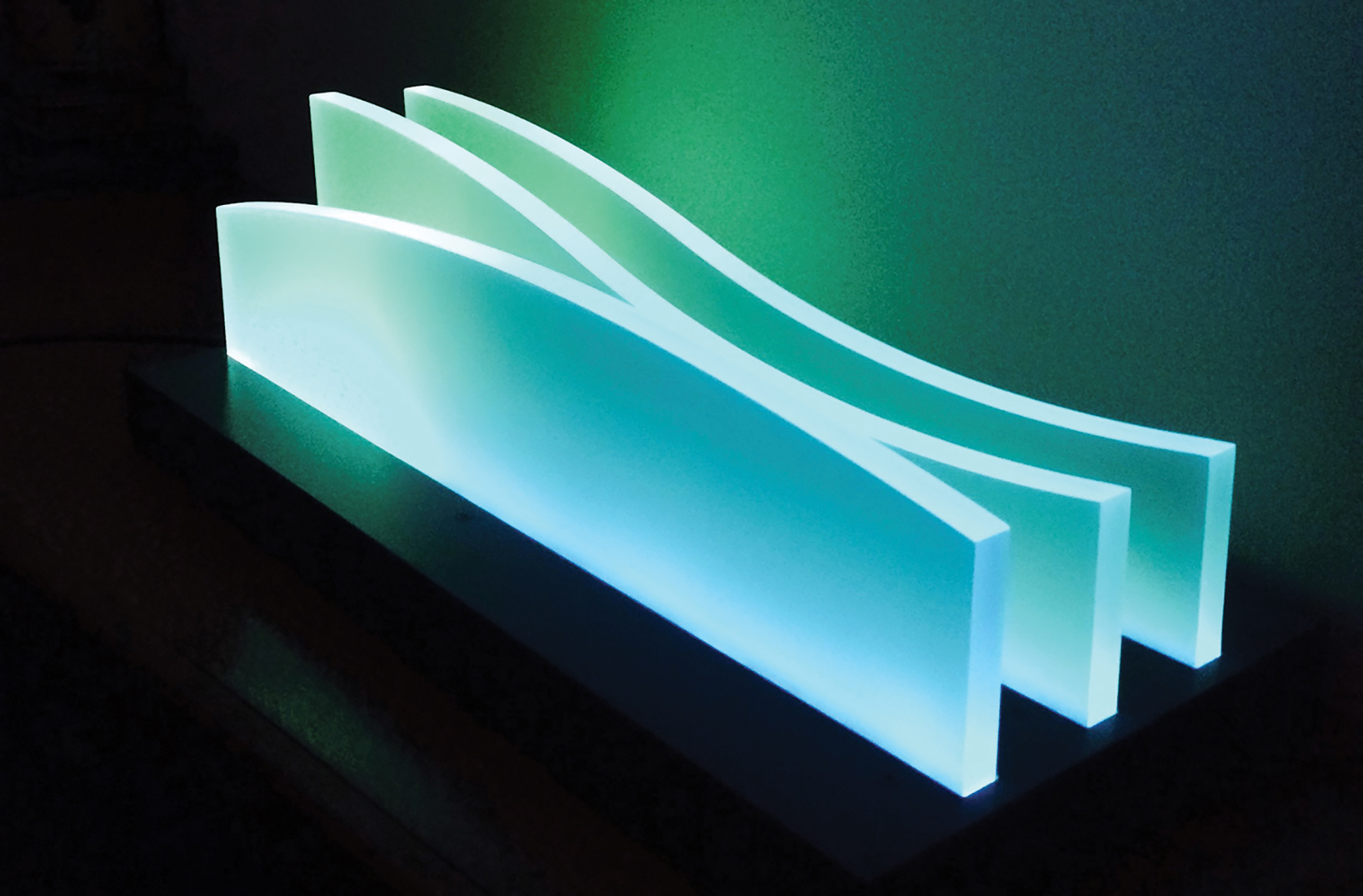

ARTfx designed and fabricated an “Ice Block” light fixture for Mohegan Sun, a casino and resort in Uncasville, CT, and a “Waves” fixture for Hartford Funds, a Wayne, PA financial services group. While the casino was a return customer, the financial company was new, a referral to a new salesperson, according to Lawrin Rosen, president of ARTfx.

Mohegan Sun was searching for a coordinated look for existing glass architectural features while Hartford Funds wanted a reception showpiece involving back-lit acrylic for their lobby. The Ice Block fixture for the casino took only one drawing for client approval, a hand sketch translated in CorelDRAW, Rosen says. For the Waves sculpture, the ARTfx art department produced four drawing iterations (also using CorelDraw) based on brand guides provided by the financial services client.

Hiding the hardware for the “Waves” light sculpture required a low-profile cabinet for the acrylic blades.

The fabrication shop shaped the Ice Block on their Gerber Sabre 408 CNC router, while Waves involved both their Gerber AR600 and 408 routers as well as the shop’s HP Latex 360 printer. They packed the Ice Block fixture with BitroGroup’s Bantam Plus 6500k LED modules to be lit by Mean Well power supplies and the Waves sculpture with Bitro OpticsPRO Max 5000k modules, also destined for Mean Well power.

“The major challenge [for Ice Block] was spraying the routed acrylic to match the glass coloration,” Rosen recalls. With the Waves sculpture, devising a low-profile cabinet that would hold the blades of acrylic without visible hardware presented the main problem. Both projects were installed where the general public could touch or handle the fixtures. To safeguard them, installers used stronger adhesives than usual (i.e. Lexel sealant, Resin Bond adhesive and 2-part epoxy) and mechanical fastening.

Unfortunately, not every element of the casino project stuck around as well as the finished fixtures will. “Our control samples for the client on the Ice Block project went missing from the project manager’s desk before they awarded the project to us,” Rosen says. He wonders where that Ice Block might have slid off to… “Competition?” he wonders. In any case, his advice for creative LED projects is to hang onto proprietary R&D samples. Do not leave them with clients, he cautions.

The new LED-illuminated sign pole for Nails 1st under construction at Widmer Sign.

LIGHTED SIGN POLE

How do you stop customers from crashing into your sign pole? This was a very real problem for Nails 1st in South Abington Township, PA, according to Teresa Carichner, project manager for Widmer Sign (Scranton, PA). “This particular location has a very small parking lot and customers were having trouble seeing the pole,” she says. “Despite bollards, the pole was hit several times.”

Carichner devised a creative solution for making the pole more visible by illuminating it and proposed the idea to the customer in the first design concept. The transformation happened in steps over a few years, she says, inspired by a related project for the salon.

In 2018, Widmer Sign had designed a unique roof sign for Nails 1st, with channel letters illuminated by RGB LEDs, as well as two standard illuminated swirl channel shapes. Carichner knew right away that she wanted to bring those swirl channel shapes to the road sign — but still the problem with the pole remained.

Widmer’s designer used SA International (SAi) Flexi software to develop a sample of how the pole would look with just white acrylic and also with digitally printed 50/50 perforated vinyl so that it would appear pink during the day — to match the building sign — and change colors at night. “We like to provide a ‘night photo’ so that the customer can really get a sense of how their sign will appear at night,” Carichner says. “They quickly decided after the first samples that they wanted the pole to change colors.”

Initially, Widmer replaced the faces in the existing sign, a standard illuminated cabinet with a steel pole. The challenge lay in keeping the pole cover slim. “Getting proper lighting without hot spots was essential,” Carichner says. “We tested it multiple times in the shop to be sure the illumination was perfect with the perforated pink vinyl.” The vinyl used was ORAFOL’s ORAJET 3676 60/40 (one-way vision) with ORAGUARD 297GF Optically Clear laminate.

Customers kept crashing into the sign pole in this tight parking lot. No longer!

Widmer Sign counted on their Roland VersaCAMM VP-540 54-in. eco-solvent Inkjet printer/cutter and double-strike ink to achieve the rich colors of the digital prints. The fabrication department fired up their Computerized Cutters Accu-Bend channel letter bender and Accu-Clinch rivet machine, as well as their ShopBot CNC router for the channel letter swirls saddling the top of the sign.

“We used G2G Lighting’s Trico DMX RGB Modules with a 160° viewing angle,” Carichner says. Changing the design of the sign to a flag mount (from a single, center-mounted pole) also served to help protect the sign from delivery trucks. In addition, Widmer installed new bollards to add protection for the pole.

“Challenges can create opportunities,” Carichner says. “And test your lighting applications in house whenever possible! Our shop and the customer just had so much fun with the project design and got lost in the creativity of it all!”

PHOTO GALLERY (21 IMAGES)

Mark Kissling is Signs of the Times’ Editor-in-Chief. Contact him at mark.kissling@smartworkmedia.com.

SPONSORED VIDEO

Who’s Steering Signs of the Times?

We dive into the history of the sign industry’s oldest trade journal, highlighting some interesting facts about how it all started to where it’s headed. Did you know that Signs of the Times is nearly 120 years old?

You may like

Canon U.S.A. to Host Webinar on AI Integration in Business

21 Highlights from the American Sign Museum Main Street Expansion

From Chips to Hip

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet2 weeks ago

Tip Sheet2 weeks agoSign Tips for Construction Fence Graphics and CNC Tables

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Wrap Shop Plots to Take Back a Poached Installer

-

Paula Fargo3 days ago

Paula Fargo3 days agoSelling Your Sign Company Via the Franchising World

-

Photo Gallery23 hours ago

Photo Gallery23 hours ago21 Highlights from the American Sign Museum Main Street Expansion

-

Signs of the Times4 days ago

Signs of the Times4 days agoDecember 1917 Signs of the Times Cover: Safe for Democracy

-

News1 week ago

News1 week agoMUTOH Introduces New Single-Pass ADA Features

-

Special Report1 week ago

Special Report1 week agoThe Wide World of Non-English Signs

-

News2 weeks ago

News2 weeks agoWells Fargo Sign Removed From Jacksonville Tower