HAVE YOU CONSIDERED adding engraving capabilities to your shop? This may sound like an odd question to ask signmakers, but the reality is that engraving and signmaking are very similar businesses. Both produce a product used to convey a visual message. Engraving can add a number of new products to your catalog, ranging from simple name tags to elaborate through-cut pieces and displays. You can get great results with mechanical engraving tools, but if you want to produce large pieces, you need a laser engraver.

Laser engraving machines have been around for a number of years and they once had a reputation for being slow, hard to operate and prone to breaking down, but today’s units are faster, much easier to use and relatively bulletproof — if you are willing to invest in the right machine. Research can help you find low-cost laser engravers, but you should look at the specifications, materials they can handle, warranties, support and actual reviews. Your best bet is to go with an established company specializing in laser engravers, one that will stand behind its products.

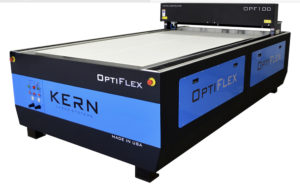

So, what do you need to look for in a laser engraver? Consider the types of products you want to produce in the near term and future. What size pieces do you want to produce — how large? If up to 4 x 8 ft., then you will need to look at exposed flatbed machines that resemble CNC routers. A fairly typical size is 3 x 2 ft. for a cabinet-style engraver, but larger options are available. You also need to look at the maximum material thickness the machine can handle to ensure it will work for your applications. To be clear, just because a machine can handle material an inch or more in thickness does not mean it can completely cut through it.

Among the many products offered by shops, laser engraving closely resembles signmaking.

This point brings up the issue of cutting vs. engraving. Engraving, of course, takes place on the surface of the material while laser cutting burns completely through the media. The manufacturers will be very clear on what materials can be engraved and/or cut. In most cases, what a laser can handle depends on two main factors: the laser’s wattage and the type of laser used. Power is fairly easy to determine. A lower-powered engraver may have a 30W laser. This will be fine for organic materials such as wood and leather while also being suitable for plastics and some soft metals. If you want to cut and engrave on a wide variety of materials, then you should opt for a higher-wattage laser in the 60W to 300W range.

You may find that most laser engravers use CO2. Another, more expensive type is a fiber laser. This solid state laser uses less power than CO2, but offers better cutting capabilities and can easily handle metals. Some manufacturers offer hybrids that combine both CO2 and fiber lasers in the same machine.

As a final note on laser engravers, you will likely need to provide shop air and fume extraction, as noxious fumes can be produced during the cutting/engraving process. You may also want to ensure the manufacturer offers optional add-ons for such capabilities as rotary engraving for trophies, awards and the like.

All in all, a laser engraver is a great addition to a signshop. You can work with a myriad of materials and most modern machines will engrave at fairly high rates of speed (120 in./sec.) and high resolution (1,200 dpi and higher). Solid machines start around $18K and go up from there.

PHOTO GALLERY (6 IMAGES)

Advertisement

Tip Sheet3 days ago

Tip Sheet3 days ago

Business Management2 weeks ago

Business Management2 weeks ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Real Deal4 days ago

Real Deal4 days ago

Editor's Note1 week ago

Editor's Note1 week ago

Benchmarks15 hours ago

Benchmarks15 hours ago

Line Time2 weeks ago

Line Time2 weeks ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago