Design

Comin’ at Ya!

A primer in lenticular signage

Published

18 years agoon

In a competitive marketplace, one way to stand out is to display a sign so strikingly different that everyone notices it. If you can’t win them with the message, get them with the medium, in particular, lenticular image displays.

While lenticular imaging still occupies a niche format in sign display, advances in processing software, lenticular lenses and expanded lens-size capabilities make the format more sign-production friendly.

Lenticular imaging emerged around 1903. However, not until the 1960s, with plastic lens advances, was it able to really take off as an imaging-display process.

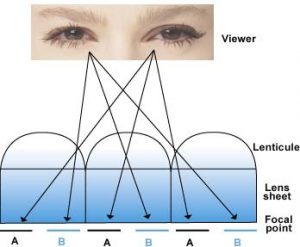

Three-dimensional lenticular images are created using several photographs (or in the case of digital imaging, similar views) of an object, each at a slightly different angle. After individual images are interlaced, or woven,” together, the composite image is printed as an interlaced photograph or graphic image. The final output is then matched and laminated with a special, high-resolution, multi-faceted (lenticular) lens that creates 3-D or animated signage.

As the viewer peers at the lenticular picture, the lens face splits the image into a series of left and right views that are optically combined by the viewer into a single 3-D or animated image.

In terms of effectiveness, lenticular displays present striking 3-D images that project their scenes forward or backward into space from the image plane of the sign. They also present dynamic animation and motion effects.

An in-depth view

Not to be confused with holography (which is a different form of 3-D imaging), lenticular imaging is a highly effective display format for small- and medium-sized specialty signage. Lenticular effects maximize a sign’s presence where depth and motion become the dominant part of an image composition. Also, lenticular signs involve viewers because they’re seen close up rather than from a distance, such as billboards that are passed at 70 mph several hundred feet away.

In most cases, viewers viscerally react to lenticular effects. They move around to see if the motion projects into space; the temptation is to touch the image, even though the viewer knows it isn’t there. Lenticular uses include tradeshows, point-of-purchase displays, direct-mail pieces, collateral marketing, movie posters and, to some degree, billboards.

Learning the process

Making lenticular images is very straightforward — essentially, it’s similar to producing most conventional sign projects (see sidebar above). The process uses standard signshop tools, including computers, software, printers and sign-display cabinets. Once a lenticular is printed, and the image is laminated to a lens, the image is mounted to a sign frame or placed in a light cabinet, ready for display.

Lenticular imaging’s unique technology (types of visual effects, applications, lens matching for appropriate effects) involves learning the craft’s technical specifications and successfully commun- icating these features and benefits to customers.

Signmakers should collaborate with a lenticular provider to learn about set-up — specifying and laminating lenses, and interlacing image files. Because repetition breeds confidence, signmakers can easily gain more lenticular projects.

Max Smith, vice president of Microlens Technology (Charlotte, NC), a company specializing in developing lenticular lenses for point-of-purchase (p-o-p), poster and sign formats, sees the challenge of converging lenticular production and sign-display manufacturing into a new business of creating 3-D or animated display products.

Max asserts that pre-press or graphic-production houses selling conventional printing can adopt lenticular technology. Technically, he explains, it’s no different, except for interlacing the print file at the beginning of the project and adding the lenticular lens at the end.

In the past, lenticular printing has always been seen as a novelty market, making winky-blinkies, postcards or trading cards. Now it’s different. There have been vast technological improvements, and output has more serious market options.

Max says Microlens can package lenticular signs into a mainstream advertising medium by creating large (movie-poster size or bigger) displays that can be produced in affordable, short-production runs.

Currently, the lenticular-image process offers several types of visual effects, including 3-D projection, animation (movement of image from one position to another), morphing (one image changing into another), zoom (moving from a mid-shot to a close-up and back again) and flips (two or more images providing different views). The effect employed depends on the message to be communicated.

Factors to consider in setting up a lenticular job include the desired visual or advertising impact, placement (indoors vs. outdoors, close up vs. distance), plus image size and the number of printed units. Size is more scalable — lenticulars are now poster size, with lenses available in ranges including 22 x 28 in., 36 x 48 in. and 48 x 96 in.

Max says his market research shows that animation, rather than 3-D imagery, is more effective as an advertising medium for both attracting and retaining attention.

He explains, “We found that people retain content better from flip imagery than from 3-D pictures because they’re more attracted by the movement factor than its image-projection effect.”

In full bloom

Ramesh Lalchan, the lenticular provider at Mirage, (Montreal, Quebec, Canada), a company that specializes in lithographic, photographic and large-format printing, claims the lenticular industry has grown “from a cottage industry to a full-bloom industry.”

Mirage transforms many printing projects into lenticular displays with an output ranging from postcards to large-format posters and signs. Between 30% and 40% of the company’s printing jobs now involve lenticular signage.

“It’s an area that’s constantly growing,” Ramesh says. “We’ve produced at least 200 different lenticular projects over the last year.”

Mirage works with ad agencies and signmakers who provide finished images to their customers, who, in turn, deploy them back to their clients for display in the marketplace.

At minimum, clients must submit a digital image in a Photoshop .TIFF format that’s ready for interlacing manipulation. At that point, Mirage interlaces the image to a specific pitch and lens. Sometimes “lenticular-literate” clients create their own interlaced files, which they forward to Mirage. The company then prints the image and provides the final lenticular project.

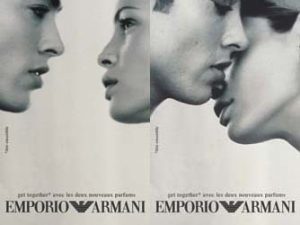

Ramesh cites two recent lenticular projects that were successfully distributed as sign-poster displays. The first client, Armani, requested an advertising poster for installation in transit shelters. Using the flip process of storing and switching different images on one sign, Ramesh created a three-channel (three-image) configuration, printed as a 4 x 6-ft. poster onto Duratrans (a translucent plastic film), placed in a backlit cabinet and distributed to more than 250 transit shelters in several European countries.

In another project, a swimwear company commissioned more than 1,000 lenticular prints of a p-o-p poster that was mounted on store-display racks in a multi-city product promotion. From these displays, Ramesh notes there was a direct correlation between increased sales and stores with lenticular displays.

Clearly a trend

Another successful provider of lenticular printing, specialty printer Service Litho (Oshkosh, WI), provides UV printing, foil embossing, die cutting and fulfillment. Lenticular printing has become a valuable addition to its business.

CEO Steve Elbing notes how his company “inherited” lenticular printing by absorbing another printing company.

“At that time,” Steve says, “I knew about lenticular imaging as a printing option that we could offer to our customers. But the real question was, ‘Is this going to be a fad or trend?’ With our continuing customer involvement, lenticular printing is clearly a trend and has offered us many opportunities with p-o-p, tradeshow, window-display and direct signage projects.”

Service Litho account manager Jay Feucht noted many clients are looking for more eye-catching sign solutions and that the company presents lenticular imaging “as a graphic application to enhance artwork and increase customer awareness.” After clients provide flat artwork, Service Litho “massages” it, prints it and sets up the image as a final lenticular piece.

Though clients with more lenticular literacy will provide interlaced files, the company prefers to start with customer-supplied artwork and finish by shipping the completed product.

Jay recalls producing an in-store beer display with a 24 x 36-in. lenticular poster. The poster featured a two-channel flip that alternated between an image of the product and a text message.

Jay says, “Altogether, we made 4,000 units. With a deadline of one week, we produced, printed and presented the final poster to the customer. To maximize the sign’s visibility, we also printed a 2-D version of the advertisement on the reverse side, allowing people to see it from whatever direction they passed the sign.”

For another project, Service Litho incorporated 2-D and lenticular printing to produce 3,500 units of a Kool-Aid beverage promotion — an in-store, corrugated “header” display.

Because the client requested an advertising display whose message “visually popped,” Service Litho recommended the creation of two lenticular elements — a hand pouring a pitcher of Kool-Aid and another hand waving a magic wand. The two lenticular elements were applied to a completed 2-D litho print and integrated into the overall sign.

Jays says that the happy customer re-ordered an additional 2,000 displays for the marketing program’s continuing promotion. He also says at least 25% to 30% of customers who worked with the medium were repeat customers who use it continually for different advertising projects.

Hypergrowth

In the future, lenticular imaging is expected to offer diverse applications, including flexible lenses for the apparel market and ultra-thin lenses for disposable packaging. Max says he can foresee a printer feeding a sheet of lenticular lens material through a digital-printing press and producing up to 200 offset-printed lenticulars a day.

Lenticular production’s financial outlook seems poised for hypergrowth, considering it’s hardly penetrated display-signage’s market opportunities. Formerly a cottage industry of novelty 3-D effects, lenticular imaging now shows signs of maturing into a major advertising medium.

How to Produce Lenticular Signs

To qualify a lenticular customer, determine what the image will do (animate, flip or provide 3-D) and the distance from which it will be viewed. That, in turn, will determine how the image will be interlaced and the type of lenticular lens needed for the final effect.

Knowing the extent of a print run ensures cost-effectiveness. Printer formats (large-format inkjet, offset, lithography and screenprinting) are also important because print quality will determine the type of lenticular lens for the final image. The final component of image quality, lens resolution, is defined by lenticules per inch (lpi); increasing the lpi calls for higher printing resolution.

Several basic steps comprise a lenticular project:

- Digital-image preparation. The completed image is imported into Photoshop for touch-up and final preparation. Whether the image is 3-D, flip or animation, two or more images (an image set) usually will be part of the final display. Completed images are transferred to FLIP!, an interlacing software program.

- Pitch test. A pitch test allows you to select a lens with the correct lpi to interlace the image. The result of the pitch test determines the setting (the true number of lenses per inch) for the interlacing software. This produces a properly composited, hard-copy print that matches the specific lenticular lens that creates its visual effect(s).

- Interlacing using Flip! software. Creating a lenticular display involves “weaving” (interlacing) images into a single composited image.

- Printing. Once images are combined and final size is determined, the composite is sent to the printer for a hard-copy output. Large-format, inkjet, offset or flexographic printing can create an interlaced image. Printer choice depends on budget, print run, substrate and resolution quality. Copy can be output onto paper, Duratrans or, in the case of offset, screenprinting or flexography, directly to the back of a lenticular lens.

- Final assembly. The traditional assembly process “sandwiches” the lens, hard copy and base substrate into a single display. Each part is mounted to the other with an optically clear, double-sided mounting adhesive. A more advanced method involves printing directly to the back of the lens. Regardless of the method used, the assembled sign can be placed in various locations — a backlit display, sign cabinet or freestanding in a p-o-p or window display.

At the Edge of Digital Media

Digital Atelier® is a printmaking collective of three women — Dorothy Simpson Krause, Karin Schminke and Bonny Lhotka — who explore the cutting edge of digital printing, both aesthetically and technically. In developing this relationship between digital printing and art, the trio create educational and research techniques that push the boundaries of traditional media and digital art while using the lastest available resources of various printmaking and display formats.

As the three artists have separately and collectively built a body of lenticular artwork, they have not only discovered a new expressive graphic medium, but also an avid audience. From a sign-industry vantage point, anything that causes people to stop for a second look is obviously a sign of something good.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

NUtec Digital Ink Invests in Solar Energy for Facility

5 Reasons to Sell a Sign Company Plus 6 Options

21 Larry Albright Plasma Globes, Crackle Tubes and More

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery3 days ago

Photo Gallery3 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks1 week ago

Benchmarks1 week ago6 Sports Venue Signs Deserving a Standing Ovation

-

Photo Gallery9 hours ago

Photo Gallery9 hours ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Megan Bradley

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Ashley Borell