THE INTERNATIONAL UNION OF BRICKLAYERS and Allied Craftworkers (Washington, D.C.) cautions that workers who cut or drill concrete, rock or masonry are exposed to silica dust. This can make them short of breath, increase the risk of incurring tuberculosis or lung cancer, or cause silicosis, a lung disease that the U.S. Dept. of Labor defines as irreversible, disabling and sometimes fatal.

Be smart; wear eye protection and a respirator (one recommended for protection against crystalline, silica- containing dust) when cutting or drilling concrete, rock and masonry. It’s always a good time to review the seemingly simple, but sometimes problematic, act of professionally drilling and filling holes in mortar, brick and concrete.

Proper drilling and filling will save your shop time and money, and also impress your customers. More importantly, it will create a friendly relationship between you and commercial landlords who, understandably, don’t like their building facades riddled with holes.

Involuntary Expansion

More to the point is that, outdoors, unfilled wall holes eventually grow larger because the freezing and thawing of accumulated water triggers erosion, and this causes the gap to expand and grow even larger. The friendly landlord relationship is crucial, because these individuals often recommend sign companies to new tenants.

The Hole in the Wall Gang

Let’s talk about making holes in a wall. First, even though you’re not drilling all the way through a wall, look above, behind and below it before you drill. It’s even healthier to look before you bid the job. Check for vents, ducts, panels, electrical wires and conduit. Look, too, for steel beams that will really slow down your drilling.

Advertisement

If it’s a large project, consider contracting with a company that specializes in concrete core drilling and cutting. These companies cut or drill holes for plumbing, electrical and HVAC installations, as well as routing cables or anchor bolts.

The next reminder is to drill the mortar, not the brick. But, whatever the material, if it’s a silica-based substance, a hammer drill makes the whole process easier. The beauty of a hammer drill is that its internal mechanism produces a pounding action while the bit turns, so the bit bites through almost anything.

Be warned that the National Institute for Occupational Safety and Health (NIOSH) grades hammer drills as “perilously loud.” They say a drill’s noise level may be only three stages quieter than an ambulance siren. Meaning, in addition to eye protection and a respirator, you’ll want to wear ear protection. If you haven’t looked at hammer drills lately, you’ll enjoy learning that drill manufacturers have introduced the concept to the home market, so you can now buy a lighter, smaller hammer drill for those lighter and smaller jobs. Regarding buying, I’ve found most popular brands of power tools are comparable, but beware of the cheaper stuff.

The Hanging

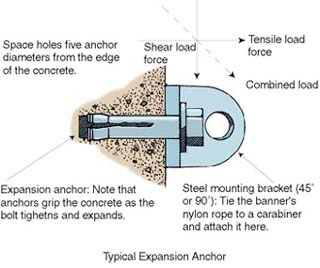

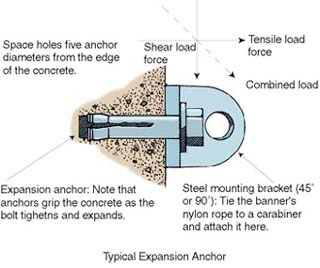

Now let’s look at hanging the banner. Once installed outside, banners can become sails and experience wind forces that can rip cords, tear fabric and jerk poorly fitted anchors right out of a wall. Plastic anchor shields are okay for light, temporary (indoor) work, but metal lag shields or expansion anchors are the better choice for outside work. You might opt for concrete screws for concrete, block and brick, but be sure to drill a properly sized hole because these must fit tightly. Choose the stainless or coated-carbon steel concrete screws for outdoor use.

There are more anchor types: wedge, sleeve, metal hit, strike and hanger, to name a few. I’m partial to metal drop-in fasteners because they’re threaded to accept a machine bolt. Thus, you can substitute a hardened machine bolt to increase the fastener’s overall sheer strength, if needed. Generally, install long fasteners in soft base materials and short ones in the harder materials.

I advise – because the real world is a tougher place than we might first imagine – that you overbuild to a reasonable extent. Also, abide by the fastener’s instructions on hole depth and diameter.

Advertisement

Patching

When filling holes, almost any material that will stay in place and not accumulate moisture will work, although you shouldn’t try to repair concrete with concrete. For concrete patching, first rid the hole of debris, then swab (brush) it with muriatic acid. This acid is dangerous, so anyone using it should wear protective gear. One source recommends you dampen the hole with the acid for several hours, but most sign installers won’t have, or take, the time.

After the brushed-on acid dries, use your choice of filler. Once the filler dries, dab it with a matching paint. I suspect that most sign installers fill holes with GE’s out-of-the-tube, silicon sealer. Still, there are other choices (such as Silox-Seal or Red Devil) and, again, you’ll find a variety of patching materials at your local hardware store. Try to do the repair on dry, sunny days, and check the material’s instructions for acceptable temperature ranges.

Tip Sheet3 days ago

Tip Sheet3 days ago

Business Management1 week ago

Business Management1 week ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Real Deal4 days ago

Real Deal4 days ago

Editor's Note1 week ago

Editor's Note1 week ago

Maggie Harlow2 weeks ago

Maggie Harlow2 weeks ago

Line Time2 weeks ago

Line Time2 weeks ago

Product Buying + Technology1 week ago

Product Buying + Technology1 week ago