Digital Printing

EFI-Vutek’s QS3200 UV-cure Flatbed and 3360 Superwide Solvent Printers

Matching machines to markets

Published

16 years agoon

In the old days, life was simple. A printer rendered a computer-generated image onto a piece of paper. To produce reports, you just bought a dot-matrix printer, and everyone was thrilled. In a fairly short time, graphics complicated the picture. You could create good-looking images, but you needed a Polaroid® print to show everyone what you created.

Things progressed from there. Dot matrix could print bit map; color was added; lasers brought near-typeset quality; color was introduced, and then inkjets made all this affordable to the masses. Soon, companies started looking for niches. Inkjets were adapted for wide-format printing. Then these printers were integrated with raster-image processors, and digital printing was born.

Not long after, this technology was adapted to printing billboards – a function that sign painters or screenprinters traditionally performed. This process required inks that could withstand outdoor conditions. Reliability, which insured clients’ deadline demands, superseded image quality. Because these images were viewed from a great distance, color accuracy superseded high-resolution output. Vutek pioneered technical solutions that allowed service bureaus to produce grand-format images suitable for outdoor display.

Because more companies now offer grand-format solutions, the question has become, how do you survive? A company must continue to innovate and seek new market opportunities for its customers. EFI-Vutek has charted that path, and its newest family members show their dedication to delivering solutions – not just products.

The QS3200

The QS3200, the company’s flagship UV-cure printer, tackles markets traditionally served by screenprinting. EFI-Vutek calls this “print-for-pay” business. This indicates the printer must create numerous types of work, but still offer top-notch quality and speed to meet demanding deadlines. Because UV-cure printers could produce short runs for a wide application range, they emerged as the best creation method for POP displays, banners and full-color sign applications.

How does the QS3200 differ from other UV-cure printers? The first giveaway is its size. Most UV-cure printers can handle 4 x 8-ft. media, when fed short side first. The printer’s 126-in. width means it can handle media more than 10 ft. wide and up to 2 in. thick. As a UV-cure printer, it can output to flexible and rigid materials.

AdvertisementAlso, its rigid-media table allows you to feed two, 4 x 8-ft. rigid boards simultaneously (Fig. 1). This effectively doubles throughput when working with POP displays. Of course, if the printer prints slowly, simultaneous printing doesn’t really mean anything.

Pay-for-print demands fast turnaround. To achieve this, shops install multiple printers and hire numerous operators, or purchase a really fast printer. The QS3200 falls into the last category. It produces throughputs up to 900 sq. ft. per hour, which translates to 22, 4 x 8-in. sheets per hour. One machine could easily produce 100 signs in less than a single shift.

The QS3200 is fast, but that means nothing with so-so print quality. EFI-Vutek doesn’t disappoint. The operator can choose between 540- and 1,080-dpi output. With the highest speeds, you’ll sacrifice some quality, but, even in this mode, the output is absolutely stunning.

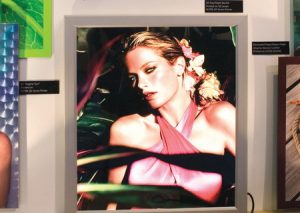

At the 1,080-dpi setting, prints have photorealistic quality and can be viewed as closely as possible. In fact, the printer can render print as small as four point. Most desktop printers can’t come close to that.

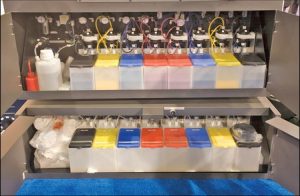

AdvertisementThe CMYKLcLm+W printer ensures excellent tones and vivid colors. The white ink, which could be the most flexible on the market, supports six different implementations: overprint, underprint, spot, underspot, fill and overspot (Fig. 2).

The Q3200’s roll-to-roll printing can produce full-color banners, window graphics, posters and even the traditional billboard applications.

Built like a tank and designed for 24/7 operations, the printer features an operator’s console driven by a fast and very intuitive UNIX-based system (Fig. 3). Fence guides facilitate rigid-media alignment. Switching from rigid to flexible media requires only two minutes. The generous, easy-to-maintain ink reservoirs mean fewer ink outages. The UV lamps have a life of 900- to 1,000-hour lifespan. With 24-hour support, you can be confident that the printer will be ready for duty.

The 3360

The versatile 3360 superwide solvent printer packs features into its industrial-grade chassis. Although the printer still targets the pay-for-print business, its output is somewhat different. For example, this printer doesn’t handle rigid materials; it’s designed for roll-to-roll operation only.

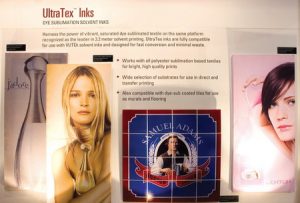

The QS3200 excels at POP pieces, but vehicle graphics and textiles aren’t its forte. However, the 3360 can really shine in these markets through an innovative option called “Fusion,” which enables this superwide-format inkjet to handle solvent and dye-sublimation inks within the same system. Both inks can be fully loaded, and the switchover, as you’ll see, takes just a few minutes.

AdvertisementYou can get the 3360 in an entry-level or a full-production configuration. Choosing entry level doesn’t mean you’re stuck; you can field-upgrade the printer when you’re ready. Let’s examine the printer configurations.

The printer can accept media up to 126-in. wide. It produces a native, economically 360-dpi resolution, with an 720 apparent-output resolution. Not as fine as the QS3200, it’s very impressive for a 126-in. wide printer. Inks can be configured to four-, six- or eight-color arrangements for the flexible printer. You can always start with four and upgrade as the need arises.

The eight-color configuration can be switched to what EFI-Vutek calls its Fast-4 mode. This allows you to run dual-CMYK configurations, which can significantly increase print speeds. You can always switch back to a true, eight-color mode.

In its photorealistic-quality mode, you can expect 600 sq. ft. per hour. However, for images viewed from a distance, you can generate speeds up to 1,622 sq. ft. per hour (Fig. 4). That’s more than 50, 4 x 8-ft. prints per hour.

You can produce some really nice billboards, quickly. The media’s flexibility – a secret weapon – will also allow even more. For example, you can print on adhesive vinyl and create fleet graphics in the fraction of the time needed by a low-end printer.

The 3360 also accepts the company’s new, corn-based Bio-Vu inks. These outdoor-rated and UV-resistant inks print on coated and non-coated media.

The 3360 has an optional system called Fusion Ink (Fig. 5), which allows you to use two different ink systems. Flip a switch, and go from one ink type to the other. You can run solvent ink and dye-sublimation textile ink in the same printer (Fig. 6). The switchover takes approximately two minutes and uses roughly $10 worth of ink – a small price to pay for having the equivalent of a second shop printer.

Get some heat presses, and you can perform sublimation jobs. For a bunch of banners, flip the switch, change media and go. Other options precisely register images for double-sided banners and double-strike printing for backlit signs.

Software

EFI has always been known as a premier supplier of RIP products. At the time of purchase, the new EFI-Vutek printers offer a choice of the Fiery XF RIP from EFI or a Colorburst RIP. The Fiery XF RIP’s dedicated-hardware (user-supplied) software can be accessed from the shop’s local area network. Myriad users can submit jobs to the RIP, and unlimited hot folders can be configured to manage different jobs. Macs or PCs manage the RIP, and the wizard-driven color-management tasks are easy to use.

You can optionally select the Colorburst RIP software, one of the fastest, most feature-rich RIPs on the market. If you already own Vutek printers, you probably own this RIP. If it’s your first EFI-Vutek printer, Fiery will probably be the way to go. Both products are excellent, so you can’t make a wrong choice.

Conclusion

EFI-Vutek takes a market approach to create a new product, and, so far, there’s no one ideal technology. If your customers want rigid material, banners and signs, the QS3200 will do the job. If you want to produce more large, outdoor work; fleet graphics; and maybe textiles or other dye-sublimation applications, then the 3360 is a clear choice. Both printers are industrial quality, easy to operate and backed by a solid-support staff ready to help 24/7.

Key Information:

EFI’s VUTEk Mfg.

One VUTEk Place

Meredith, NH 03253 USA

(603) 279-4635

(603) 279-6411

www.efi-vutek.com

Company Profile: EFI-Vutek Inc., an American manufacturer founded in 1988, is a worldwide supplier of superwide inkjet printers to the graphic-arts market, with advertising applications including billboards, fleet graphics, banners, bus shelters, POP displays and posters.

Contact: Jane Cedrone, marketing communications mgr. JCedrone@efi.com

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago30 Snapshots of the 2024 ISA Sign Expo

-

Paula Fargo1 week ago

Paula Fargo1 week ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Projects1 week ago

Projects1 week agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Alicia Brothers

-

Signs of the Times2 weeks ago

Signs of the Times2 weeks agoJuly 1919 Signs of the Times Cover Features Woman Installer

-

Business Management6 days ago

Business Management6 days ago3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market