Best Practices

Estimating Neon Prices

Neon-pricing strategies

Published

18 years agoon

PRICING IS ALWAYS a critical subject, especially in the relatively small neon industry. Every neon shop is vulnerable to cutthroat low bids, negative word of mouth and numerous additional pitfalls. Perhaps this explains why few books and publications address this subject. Only one how-to pricing guide serves the beginner; ST publishes the Neon Cost Data Guide, which should be used as a rough guide only.

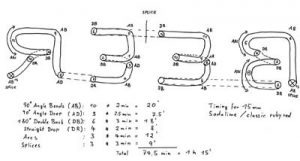

A garden-variety beer sign, a staple of many neon shops.

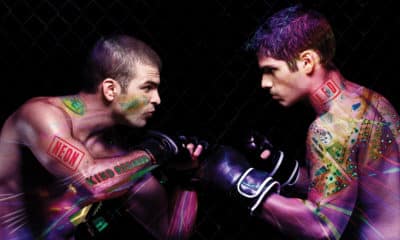

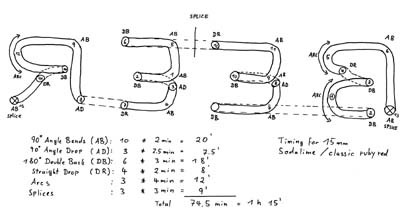

A sketch of the bends required to achieve the “Beer” copy, with each bend’s completion time. It’s important to incorporate a “fudge factor” for many jobs, such as intricate work or projects requiring a quick turnaround. This example represents a single-sign sale. Clients buying multiple signs would receive a substantial volume discount. Further, the labor rates and fabrication times are hypothetical, and not necessarily representative of standard, neon-sign fabrication.

Despite limited discussion, accurate estimating may determine life or death for many small neon shops. If your bid is too low, you won’t turn a profit; if your bid’s too high, your competition will get the job. This excerpt from the aforementioned guide rings true: "Good pricing is a cornerstone of any company. The entire direction, possibly even the existence, of your company rests upon the accuracy of your…pricing."

Two approaches

Good estimates must be based on experience; they can’t be pressed into simple schematics. Every sign job is different. Experience helps you foresee most potential problems that standard schemes would miss.

For neon, two price-quotation methods are common. Most commonly, quotes are based on the straight length of tubing, which falls under three bend categories — straights, block letters and curved scripts. Further, there’s the choice of clear or colored glass. With six resulting base prices, you merely multiply by the straight length.

Some beginners in the trade follow the Neon Cost Data Guide’s simple approach of quoting each character based upon height and typeface. You’ll achieve a more appropriate total by pricing materials and labor separately. Just imagine having quoted a sign by the footage of straight length without examining the actual pattern, and then recieving a pattern with 11/2-in. tall, script letters or a tube with a different color (read: splice) every four inches.

AdvertisementMeeting client needs

Problems usually arise long before you begin pricing. Clients provide different sketches and reference materials. One client might present a business card and say, "Make my logo in neon to fit my shop window," which requires a different strategy than the client who steps in with an actual-size, reverse-glass drawing on heavy paper. Often, "neonizing" a font or logo requires more work than the actual fabrication (see ST, August 2001, page 24).

Thus, when complicated layouts are necessary, only give the client a conditional estimate on the cost of an accurate estimate that can be done only after the completed layout. Most shops partially reimburse this amount once the client orders the sign.

Now, let’s assume you have a usable pattern. First, measure the total straight length of tubing with a map wheel, or your blowhose and yardstick. This number determines the correct transformer size. If you prefer to price neon by the foot, you’re already done. $image1

Or, use this number and input it into one of the Neon Cost Data Guide’s tables. Be careful, because some instructions and advice aren’t easy to understand. Some tables include costs from other tables; be careful not to duplicate charges for glass or wiring.

For detailed calculations, I take the pattern and draw where I want to make the splices. Using the blowhose, I determine the length of individual sections and, therefore, the number of glass sticks I’ll need. By moving some splices, you may save several sticks on a larger sign. By adding the cost for electrodes, mercury and a flat charge for rare gas, you can obtain neon’s material costs. If you supply neon with transformers, obtain the correct transformer size and model from the loading charts using the total number of units and tube length, and add the transformer cost.

The price of sweat

When estimating labor, I go through the pattern step by step, marking each bend with the type of bend and, in the case of complicated patterns, its sequence number. A helpful book for the beginner is ST’s Neon ABC Alphabets, written by Dean Blazek.

After marking the bend types, I count the total number of bends or splices needed throughout the pattern — don’t forget the electrode splices. From experience, I know the timeframe for each of these bends. A slight curve takes much more time than a 90° bend in the crossfires. Multiply the total number for each bend, by the time needed for that type of bend, and tally the results. This gives you an accurate bending timeframe. Add at least 30 minutes for pumping — remember that pumping a good-quality tube requires at least 30 minutes — and allow time for aging, painting and commissioning. Doing so for the "Schaefer" sign featured in the graphic, I obtained:

- 14 arcs

- 3 angle bends

- 8 angle drops

- 14 double backs

- 2 straight drops

- 4 splices

Including pumping and fabrication, this sign incurred 2 hours and 50 minutes of labor; the "Beer" sign required one hour and 45 minutes.

Fudge factor

Before determining final costs, I carefully consider the type of job and add some "risk" time or material to the first estimate when a job is large, complex or a rush order. Every experienced bender knows that not all colored glass is compatible, and ruby red is much more prone to cracking than others. Complex, tightly packed bends require careful preheating of subsequent bends so as not to crack preceding bends (consider 2-in.-tall, Chinese characters made with 8mm, ruby tubing).

Also, the more you must rush a job, the more likely the last bend or splice will crack and force you to start over. Depending on the job’s specs and your own skills, doubling necessary labor time and materials might be needed. In this case, multiply the total time by the average hourly rate. $image2

Materials and labor calculated this way comprise your cost. Work must provide more than a little satisfaction, so you must make more money than your costs. As such, I calculate material and labor cost with my fun factor, a multiplier between 1.1 and 2, depending on the job and client, to obtain a sale price.

When stating payment terms, keep in mind every neon sign is unique, so it’s wise to ask for at least a 50% down payment before starting. Serious clients will understand and not hesitate to make the down payment. If they’re reluctant, be careful.

Estimating neon installations is a different subject, which I’ll cover in a future "Neon Techniques" column. Unknown site details and unforeseen problems arise. Identical installs simply don’t exist.

In summary, I’d like to offer two final remarks:

- My estimating process is derived from consulting many neon shops. I’ve never sold or made commercial signs myself; and

- Clients always ask for the impossible to be done yesterday at an unacceptably low price. Let them know that quality labor and materials take time and have a cost. And, witchcraft is extra.

Material and Labor Costs for the Schaefer Sign

Material Cost

Item Quantity Per Unit Cost Total

8mm, clear glass sticks 4 $0.45 $1.80

10mm/25mA electrodes 2 $2.03 $4.06

Miscellaneous (paint, tubulation, mercury, rare gas, etc.) @ flat rate $5.00 $5.00

Total Neon Materials $10.86

900V/ 25mA transformer 1 $80.25 $80.25

Steel mounting frame 1 $27.50 $27.50

Tube supports 8 $0.22 $1.76

Silicone boots 4 $0.56 $2.24

Miscellaneous (screws, washers, nuts, rivets, etc.) @ flat rate $7.50 $7.50

Total Fabrication Materials $119.25

Materials Grand Total $130.11

Labor Costs

(All items are based on labor rate of $43.50/hr.)

Activity Time Total

"Schaefer" text fabrication 2 hrs. 50 min. $123.25

30% "fudge factor" for 2-in.-high script $36.98

$160.23

"Beer" text fabrication 1 hr. 45 min. $76.13

Mounting 1 hr. 30 min. $65.25

Total Labor Cost $301.61

Total Cost

Factor mark-up multiplier of 1.35 $431.71

Sale Price $582.83

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Avery Dennison Adopts Mimaki Printer for Traffic Sign Print System

Fiery Releases SignLab 11

21 Larry Albright Plasma Globes, Crackle Tubes and More

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Advertisement

Most Popular

-

Tip Sheet3 days ago

Tip Sheet3 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management1 week ago

Business Management1 week agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Editor's Note1 week ago

Editor's Note1 week agoWhy We Still Need the Women in Signs Award

-

Maggie Harlow2 weeks ago

Maggie Harlow2 weeks agoThe Surprising Value Complaints Bring to Your Sign Company

-

Line Time2 weeks ago

Line Time2 weeks agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines