Sign blanks come in many shapes and sizes, and are made from a variety of materials. Selecting the right one for your customer’s sign is esssential.

WHEN DESIGNING A sign for a customer, how much time do you spend thinking about the substrate options for where the design will be applied? In many cases, this is a non-issue, as the type of sign or its ultimate location will determine the blank to be used. For example, backlit signs require some type of translucent plastic, like acrylic, but for many other signs you have a choice, and will want to select the right blank for the design. Let’s take a look at some sign situations and the types of blanks for the jobs.

Real estate and other hanging signs present a number of options. The most popular selections are aluminum blanks and corrugated plastic. The blanks are cheap, come in standard sizes and handle outdoor conditions well. In many cases, aluminum signs also can be easily changed. Corrugated plastic is typically cheaper but may be more susceptible to weather conditions.

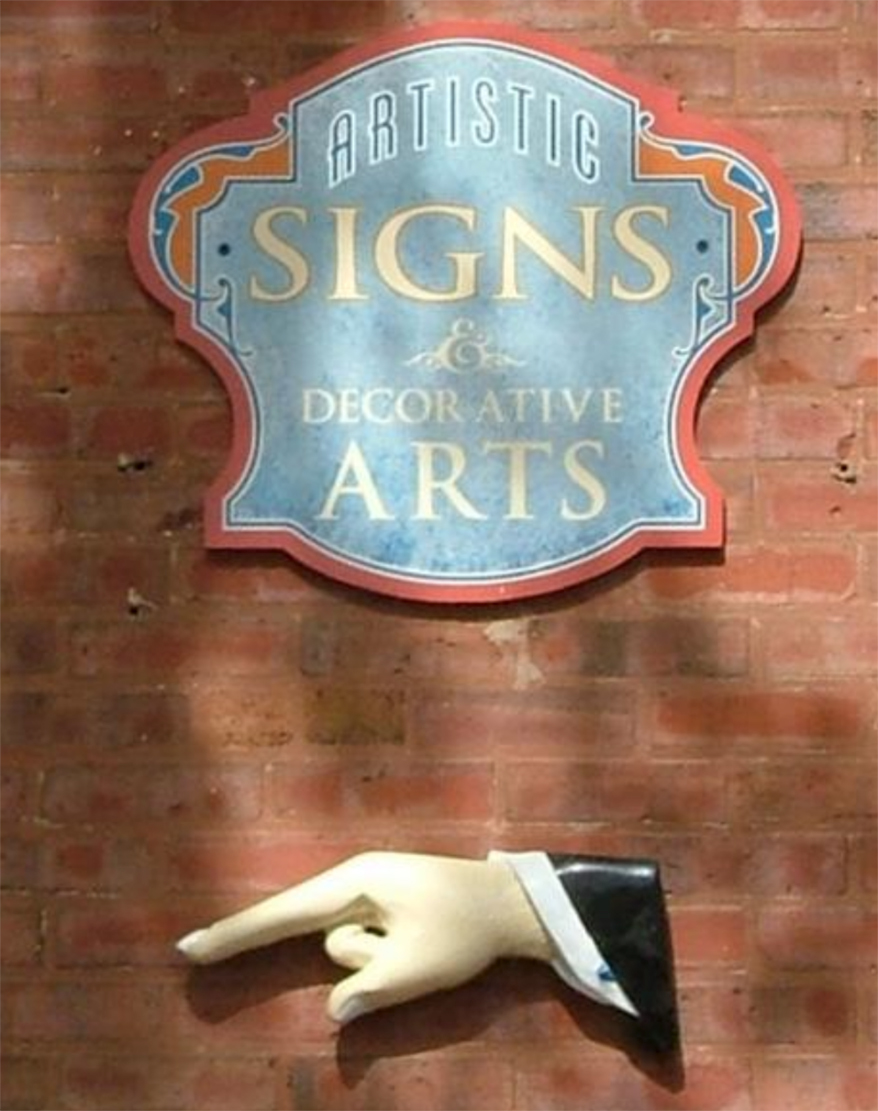

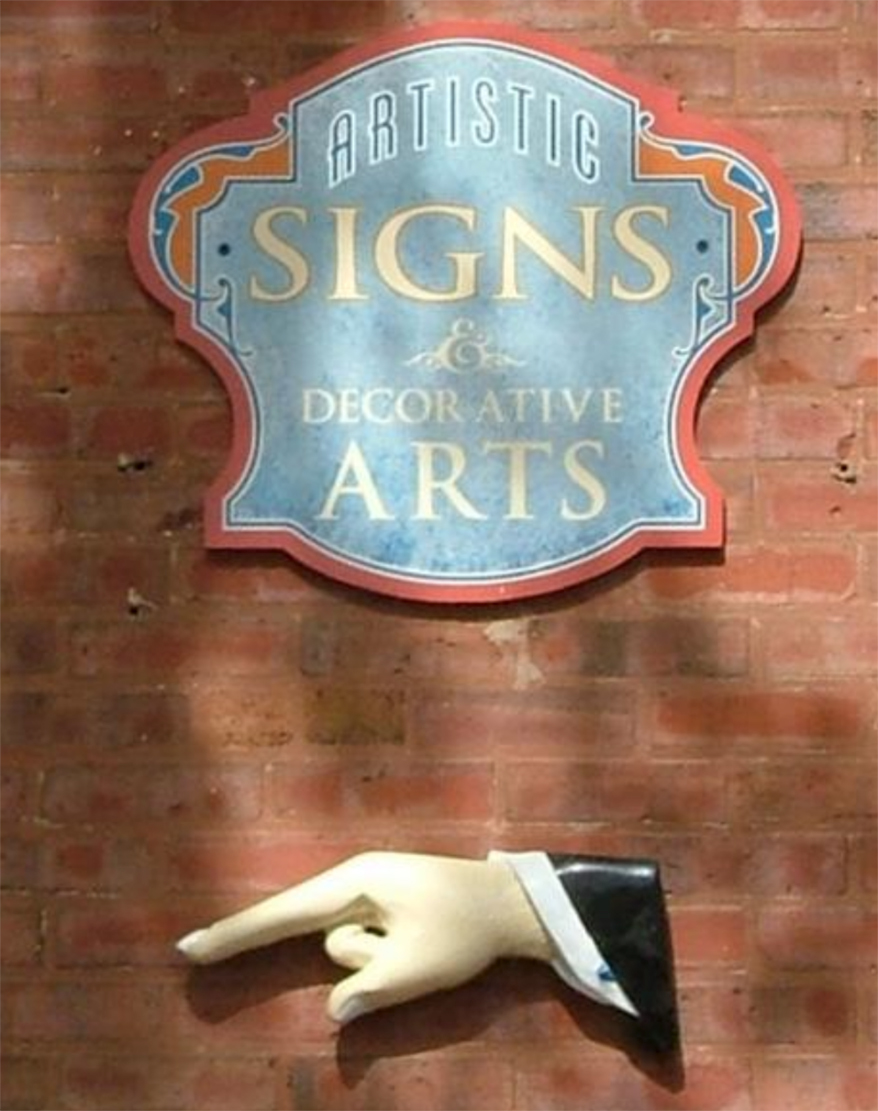

For more traditional storefront signs that are not backlit, many signmakers choose an exterior-grade plywood. Typically available in 4 x 8-in. or 4 x 4-in. sheets in either a primed or painted surface, this material readily accepts vinyl, painted or printed graphics. The outdoor durability is great and the edges can be routed or cut with typical shop tools to create non-rectangular shapes. Even if you don’t have the tools or time and you want a circle, oval or sculpted blank, you can find a number of companies offering PVC blanks in various sizes and shapes.

However, if your shop is proficient in carving, CNC routing and/or sandblasting, the above materials won’t work for you. For these sign types you need a soft, but rigid material. Redwood is available in various-sized blanks, though it can be very expensive. Large boards are typically made by gluing strips together to create a rectangle or square blank. When sandblasting, the glue joints may show up in the blasted area, in addition to the hard grain. Sign foam (high-density urethane or HDU) is lighter than and the best alternative to wood. Sign foams are easy to carve, sandblast and rout — and have no knots. After priming, the foam accepts paint and is very weather-resistant.

You may want a flat, rigid board for mounting or hanging, and corrugated plastic and aluminum sheet options may be too thin, while MDO plywood or wood blanks may be too thick. A good alternative is an aluminum composite material (ACM), in which a foam core is sandwiched between two aluminum sheets. The boards are rigid, lightweight and easily accept graphics.

Advertisement

Obviously, there is a great variety of sign blanks available on the market. Be sure to consider the blank material as part of your design. You may be able to offer options to your customer and select a material that will last a long time under the expected conditions.

PHOTO GALLERY (6 IMAGES)

Tip Sheet1 week ago

Tip Sheet1 week ago

Photo Gallery3 days ago

Photo Gallery3 days ago

Ask Signs of the Times5 days ago

Ask Signs of the Times5 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery10 hours ago

Photo Gallery10 hours ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Paula Fargo9 hours ago

Paula Fargo9 hours ago