Residing in a shop on a somewhat secluded cul-de-sac in a Lexington, KY industrial park, Integrated Signs’ environs don’t reflect the far-reaching scope of its work. Yet, its signs have crisscrossed the U.S. Its signage production for Garland, TX’s Firewheel Town Center, completed in collaboration with Roswell, GA-based, environmental-graphic-design (EGD) firm Lorenc+Yoo, won the 2007 International Sign Contest’s Best of Show (see ST, April 2007, page 138).

Albert Oberst founded the company in 1981, and it’s grown into a 25,000-sq.-ft facility spread across 3.5 acres. The company fabricates, in-house, the vast majority of its architectural-sign projects, which range from ADA-compliant markers to a comprehensive, building-ID package, and performs or closely supervises installation.

“We do sub out some routine channel-letter projects, and we contract out all of our digital printing,” he said. “It’s best to emphasize your shop’s strengths. But, it’s important to maintain control of what you produce and see it through all phases to completion.”

Before the Great Recession struck, the shop completed a high percentage of architectural-sign projects as full design/builds, Oberst said. However, as developers’ project funds shriveled or evaporated, Integrated Sign has benefited from partnering with EGD firms.

“I think an architectural-sign package is best represented by a keen vision from talented designers, executed with consistent, quality materials and production techniques,” he said. “After the recession, bids became much more competitive, and these relationships [with EGD firms] have been valuable. When the client is a private entity, they won’t automatically choose the low bid. It helps to earn the respect and recommendation of design firms that understand quality, not price point, is the best long-term solution.”

The company garners significant repeat business. Thomas & King (Lexington), the largest Applebee’s Restaurants franchisee (88 locations) in the U.S., represents a good example. Integrated recently worked with Thomas & King on its store rebranding, and replaced products originally fabricated 25 years ago.

Advertisement

Regarding materials, Oberst has a very clear preference: “Except for support structures, we don’t build with steel. We’re an all-aluminum shop. Steel may be inherently stronger, but it’s so much more susceptible to rust. The programs we build are designed to last long-term. If you build with sufficiently strong aluminum stock, your signs will have all the strength they need.”

Integrated also enlists ZLite’s 7,000K LED modules for most of its electric-sign applications: “Through side-by-side trials, I’ve learned that 7,000K LEDs provide a warm glow, whereas modules with a 3,000 Kelvin-scale number can look yellow and washed out. Other products have caught up, but the ZLite modules were ahead of the curve with better lighting efficacy. As for neon, it still has a place, and can be engineered

to last a long time, but I think it’s obsolete for covered signs and channel letters,” Oberst said.

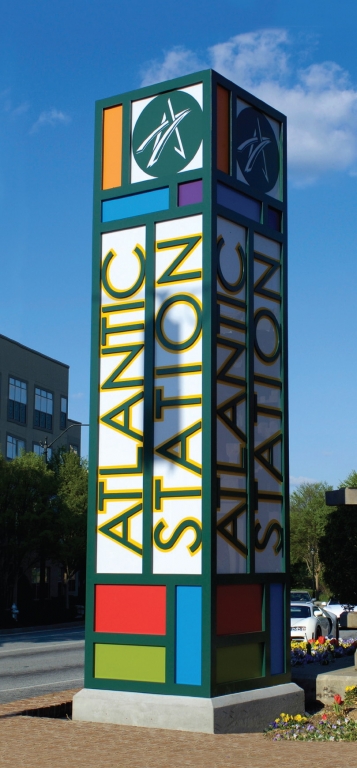

Custom-sign programs also represent a vital part of Integrated’s repertoire. Recently, Huie Design (Atlanta) invited Oberst to bid on updating gateway and wayfinding signage for Atlantic Station, a 138-acre, multi-purpose development on the western edge of midtown Atlanta, on the former Atlantic Steel Mill site. The property originally opened amid much fanfare in Fall 2005, but store sales and residential occupancy failed to meet expectations. The economic downturn that soon followed hampered the development’s success.

Looking for ways to refresh Atlantic Station’s brand, its new owners sought to upgrade the property’s original, environmental graphics.

“The wayfinding was sparse and not very descriptive,” Oberst said. “Truth be told, I got lost trying to find my way out of the parking garage.”

Huie’s designs remedied this confusion with a series of pylons, directories and building-ID signs with a vibrant color palette and highly visible letters and numerals. Integrated fabricated the panel faces from aluminum extrusions and sheet, which it coated with Matthews acrylic-polyurethane paint. Pylons comprise fabricated-aluminum tubing with Lexan® polycarbonate panels decorated with 3M translucent vinyl on the first surface. Integrated built elevator-ID signs from fabricated-aluminum faces with numerals halo-lit by LEDs.

Advertisement

Going forward, Oberst recognizes changes will likely occur within the architectural-sign market. For example, electronic-message displays increasingly integrate with, if not entirely replace, static directories.

“The sign industry is always evolving, and you have to keep up,” he said. “We’ve worked with electronic-message centers, and I’m studying new displays that have entered the market. Technologies might change, but built environments will always need graphics that both tell people where to go and help provide atmosphere.”

Tip Sheet1 week ago

Tip Sheet1 week ago

Ask Signs of the Times2 days ago

Ask Signs of the Times2 days ago

Real Deal1 week ago

Real Deal1 week ago

Benchmarks4 days ago

Benchmarks4 days ago

Editor's Note2 weeks ago

Editor's Note2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago

Product Buying + Technology2 weeks ago

Product Buying + Technology2 weeks ago

Photo Gallery6 days ago

Photo Gallery6 days ago