Metal Fabrication

Porcelain Enamel Is Here To Stay

Why this vitreous liquid is still coating after all these years

Published

18 years agoon

Porcelain enamel may garner praise from homeowners who count on its strength and cleanability as a protective, household-appliance coating. But strengthening of these attributes, additional colors and falling prices are also leading end-users in the sign industry down the porcelain path to request outdoor signage that lasts — and lasts. The discovery of intact porcelain-enameled artifacts from 2000 BC has proven its longevity.

But why use this ancient and often more costly technique? Is it worth the extra expense? And is it actually gaining in popularity among sign-makers? These are all valid questions and, with answers from those in the know — the users of the material — you may opt to rediscover porcelain-enamel signs for the first time.

Using enameling as a protective and decorative coating is a tried-and-true idea. New technologies, including an expanded color selection, have made it more versatile, and production streamlining has made it less expensive. The characteristics that previously deterred potential porcelain-enamel buyers are fewer, and the material’s positive attributes are becoming more obvious.

Fireform Porcelain, Inc., Santa Rosa, CA, a manufacturer and supplier of porcelain-enamel blanks has worked with various companies to create porcelain-enameled signs. Here are two companies that share their experiences with porcelain enamel on exterior applications. One, Design Communications Ltd., Boston, MA, takes a more involved approach with the process of panel-making by also doing some of the graphic artwork. The other, Thomas Swan Signs, San Francisco, CA, assumes a more traditional approach, acting as a subcontractor for the porcelain projects.

Design Communications Ltd.

Design Communications Ltd. uses porcelain enamel for some of its exterior-signage projects. However, it sometimes participates more with the process by handling the artwork’s color separations in-house, instead of subcontracting to Fireform. For instance, the company did all the graphics for its Metropolitan Museum of Art project. In this undertaking, it separated the colors and had the manufacturer cover the designs with the enamel.

Kyle Reath, vice president of Design Communications, says no project is too big or too small for porcelain-enamel panel usage. The company buys anything from 1-in. to 5-ft. long strips for wrapping around columns to 24 x 36-in. panels. "When a designer comes to us with an idea, we just make it happen. It’s project-specific. And as far as I know, they [Fireform] haven’t let us down with any shape or size. If things get too large, they’ll be broken up into segments."

The cost of the blanks depends on several factors, such as if the panels are flat or have returns, whether they have one or 10 colors, or if they include halftones. Reath says layouts for new projects are faxed to the manufacturer for quick price estimates.

Design Communications has used thousands of porcelain-enamel panels for its projects. In the Metropolitan Museum project, for example, Reath estimates the company used 350 panels. Porcelain enamel accounts for approximately 5% of the company’s total signage production. Design Communications marks up the manufacturer’s prices about 20%, depending on the amount of in-house involvement. For instance, with substantial in-house artwork production, Reath says the mark-up will be 50%, allowing for the cost of time and materials before the artwork gets to Fireform.

Panel decoration varies from project to project, Reath says, and Design Communications often uses combinations of materials.

"At the Metropolitan Museum of Art, we custom-machined solid stainless-steel barstock frames and set the porcelain-enamel panels into that. At Boston Common Garage, we did a custom-perforated aluminum with a certain hold pattern which we curved and laminated porcelain strips onto."

Reath explains that decorating porcelain-enamel signs is different than decorating other types of sign materials because the graphics are contained within the enamel. The graphics are permanently in place and cannot be changed, but they’re also protected from graffiti and other types of vandalism. However, if signs need changeable copy, it will be attached over the enamel with an epoxy. Some examples might be arrows or dollar amounts on parking garage signs.

Porcelain enamel’s weight problem has mostly been eliminated. According to Reath, "For the most part, porcelain is looked to when there is an exterior application or an application where children or adults or bicycle messengers or whoever can get at it. If you build a structure outside, chances are the structure is built to withstand people climbing on it or being able to touch it."

For installation, Design Communications typically uses plywood, which acts as a filler inside of the porcelain to keep it from twisting or bending. The wood is screwed into the substrate and is attached using epoxy or silicone with bolts.

Design Communications opts for porcelain for specialized applications. Reath advises clients to take the safest and most cost-effective route in the long run. "If anyone stresses to me that they’re concerned about the safety of their signs, I will strongly suggest that they consider porcelain as an option. And if the job is small enough that the set-up costs involved will become an issue, I will stress to them that it is money well spent," Reath says.

In 80% of the porcelain-enamel projects the company handles, the clients already know they want the material. Most better-known designers keep up-to-date with the latest techniques. And because porcelain enamel is more cost-effective and of higher quality now, it is gaining recognition.

Reath says, "I think that the technology that’s gone into porcelain and the quality of the porcelain is better now. The resolution is higher and the prices have come down . . . I think that clients in general are willing to spend more money now than they were 10 years ago for a quality product that’s going to last. Signs are not just something to take for granted and throw on buildings."

Thomas Swan Signs

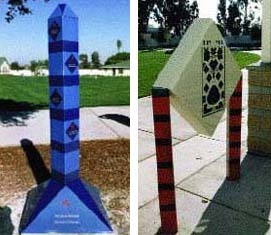

Thomas Swan Signs, San Francisco, CA, has used porcelain enamel for about 20% of its total signage to date, according to Ray Paul, a project manager for Swan. The most recent porcelain-enamel project was the Children’s Shelter in San Jose, CA. Paul says he chose porcelain enamel because of its vandalism-resistant qualities.

"The Children’s Shelter is a stopover point for children . . . so it has to be susceptible to wear and tear. So far so good. It’s been one year of super-active use," says Paul.

Generally speaking, clients who opt for porcelain are dealing with projects in high-pedestrian/high-traffic areas, such as public parking garages. Paul estimates an average cost of $60 for panels used in the company’s Bush-Polk parking garage projects. Thomas Swan’s approximate profit margin for the $60-70,000 project was 20%.

Installation poses no additional problems. Most signs Swan produces come in a hollow pan — much like a cake pan — with returns. They are delivered in this fashion to prevent warping of the porcelain. Swan then puts a metal angle on the wall, hangs the panels like a picture and drills through them. This way, the holes are drilled on the side instead of through the front.

Another method involves filling the inside of the pan with a similarly-sized piece of plywood and then attaching it to the wall by drilling through the plywood instead of the sign.

Although porcelain enamel has many formidable attributes, he adds that, as with any material, there are pluses and minuses. The obvious advantage is its resistance to harsh environmental conditions. But despite its strength, it is not completely immune to vandalism: It can be chipped or broken by extreme force.

Paul says, "If somebody wants a nice, beautiful sign, and they want it up in the air 10 ft. high, we wouldn’t recommend porcelain enamel because it doesn’t seem to be necessary. But sometimes they need something that’s long-term, and then we would suggest it."

Paul finds that potential clients aren’t usually aware of porcelain enamel’s sign application. "It’s probably more of the public’s perception of what you can do with it. A lot of people don’t even know what it is. And then you say, ‘It’s the same finish that you’ve got on your oven.’ And then they say, ‘Oh, I can scrub that stuff like crazy!’ But they have no idea how you can print graphics on it."

But, he adds, technology is making porcelain enamel more desirable than ever before.

"I’ve seen some beautiful four-color processes screen printed by these companies that are pretty amazing. So I think it’s definitely getting a much, much bigger following now than it did 10 years ago."

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Tip Sheet1 week ago

Tip Sheet1 week agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Photo Gallery2 days ago

Photo Gallery2 days ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times4 days ago

Ask Signs of the Times4 days agoWhy Are Signs from Canva so Overloaded and Similar?

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks7 days ago

Benchmarks7 days ago6 Sports Venue Signs Deserving a Standing Ovation

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Megan Bradley

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Ashley Borell