T HE SIGN INDUSTRY relies heavily on large format digital printing, from posters, to car wraps, soft signs and textiles. We tend to concentrate on the specific printing device when making purchasing decisions. Do I need a textile printer? Should I get into UV printing with a finishing machine? What printer width do I need for car wraps? We think very little of the means of transferring the final artwork from the designer’s workstation to the printed media. In many cases not taking that into account can cost you time and money.

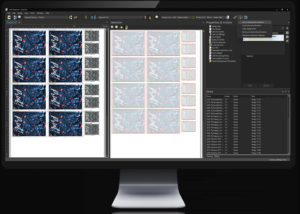

A Raster Image Processor or RIP is that critical bridge between the design and the print. In its simplest form it translates the objects (bitmaps, text, vectors, etc.) within a file into a bitmap that the printer can understand and initiates the print. RIPs differ from a printer driver like the one you installed for your desktop office printer in a number of ways. Typically the RIP runs on a dedicated server that is accessible by any number of workstations. Instead of the print process beginning immediately and relying on the workstation for computing resources, the file is merely transferred from the user’s workstation to a queue in the RIP server and the user’s workstation is immediately released. The RIP then scans the queue and processes and prints the files either in order or according to rules established in the RIP software.

Without a RIP, printing photo-realistic graphics, as for this vehicle wrap by Stoner Graphix (Hummelstown, PA), would be impossible.

Okay, it sounds like it may save some time by freeing up a designer’s workstation quickly so they can get back to, well, designing. That doesn’t seem to warrant the prices some manufacturers charge for a RIP. If you look deeper, many RIPs offer a variety of features that further enhance the printing experience and probably save money as well.

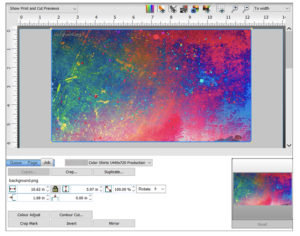

For example, some RIPs offer sophisticated nesting that combines multiple prints onto a single sheet of media. If you had several D size prints, a few A size and even an E size or larger, the operator would have to change to larger or smaller media sizes between prints.

Nesting would fit all of these prints together to conserve media. Managing print and cut files for decals or UV prints and finishing machines can be difficult. Many RIPs take care of all of the processing and can even interface directly with job management processes. Some RIPs even offer sign-specific features such as printing grommet and folding lines that eliminate the measuring and marking steps in the final steps of banner construction.

A subtle but powerful feature of most RIPs is the number of printer models they support, which includes most popular printers, plus manufacturers typically add new models as they become available. You can scale many RIPs to support multiple physical printers and create queues for various characteristics such as media width, specialty ink colors like white, and even specific queues for textile printers. You can also set RIPs to retain printed jobs so that they reprint without the need for reprocessing. That’s great for re-orders or prints damaged while handling.

We’ve really just touched on a few of the many reasons for Raster Image Processors’ vitality to any shop that uses digital printers. Many RIPs let you scale and add additional print streams so you can start out small and grow. If you are not using one now or if you are adding digital printing to your shop, then you need to see what a RIP can do for you.

PHOTO GALLERY (6 IMAGES)

Advertisement

Tip Sheet2 weeks ago

Tip Sheet2 weeks ago

Photo Gallery4 days ago

Photo Gallery4 days ago

Ask Signs of the Times6 days ago

Ask Signs of the Times6 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Paula Fargo1 day ago

Paula Fargo1 day ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery1 day ago

Photo Gallery1 day ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago