Metal Fabrication

Reclaiming an Identity

Poblocki Signs restores a marquee it originally built seven decades ago.

Published

16 years agoon

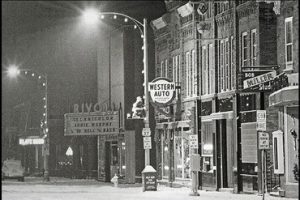

For more than 70 years, the Rivoli Theatre has attracted crowds to downtown Cedarburg, WI. But for the last three decades, this theatre has lacked one key element – the majesty and glamour of the cinema’s original marquee that once beamed over Washington Ave.

Therefore, when the Cedarburg Landmark Preservation Society took over the theater’s operation in late 2006, the group immediately sought to recreate the façade’s signature, historic signage. To complete the restoration, the society hired Poblocki, which had created the original marquee in 1936.

At the company’s 1932 inception, Poblocki sought to distinguish itself as a designer of one-of-a-kind movie marquees. During its first two decades, Poblocki built hundreds of marquees for theater companies nationwide. These iconic marquees served as vital, Main St. cogs for many small towns such as Cedarburg.

The history

In the early 1930s, Cedarburg turned a former Boerner Brothers dry-goods store into its community cinema. Built in the late 1880s, the spacious structure readily lent itself to conversion into an entertainment venue. The city renamed the building the New Rivoli Theatre and sought to make it a downtown landmark.

Bedecked with a lavish interior and an art-deco façade, the theater opened January 11, 1936. Admission was a quarter to its inaugural feature, A Tale of Two Cities, according to the theater’s website. The Marcus Corp. procured the Rivoli in 1956 and tore down the dramatic marquee in the late 1970s.

AdvertisementIn December 2006, Marcus sold the Rivoli back to the Cedarburg Landmark Preservation Society. At this point, the group was already a year into its fundraising campaign, “Revive the Rivoli.” The society set a goal to raise $800,000 to buy, restore and maintain the theater. Donald A. Levy, an attorney and the society’s vice president, became motivated to restore the theater when he learned investors wanted to turn the building into retail shops. Once the group had accrued enough funds to renovate the theater, it contacted Poblocki.

A marvelous marquee

First, the Poblocki team reviewed photos of the original Rivoli marquee from an old theater brochure. After having reviewed these photos, the design team created a scaled drawing, which the project’s architect revised to a vertical orientation to include a “waterfall”-shaped design.

Poblocki engineers utilized AutoCAD and SolidWorks 3-D software to draft the custom sign. We developed the new marquee’s overall shell, along with some of the aluminum parts developed with SolidWorks, and we rendered detailed shop drawings with AutoCAD 2004. Because the new marquee stretched across the building’s entire face and over the roof, and because we had to work around an existing, steel support structure, designing a large, attractive sign that wouldn’t overload the building’s capacity proved challenging.

After the society approved those drawings, Poblocki moved on to specifications. The society insisted on replicating the original sign’s lighting. Initially, discussion contemplated LEDs. However, finding LED bulbs that would mimic the original marquee proved to be a long, futile experiment. Ultimately, we learned that LED bulbs currently available just couldn’t bathe the marquee in the same color of light as traditional, incandescent bulbs.

Field measurements of the theater building helped determine precise dimensions. The marquee measures 20 ft. 4 in. wide x 26 ft. tall x 9 ft. deep at its deepest point. Though the new sign extends beyond the roof, it encompasses less square footage than the original.

AdvertisementCraftspeople began fabricating the designs on the shop floor in Poblocki’s 110,000-sq.-ft. facility. There, the production team decided to manufacture the new marquee from aluminum rather than iron, which was used to make the original. Aluminum proved beneficial because of its increased corrosion resistance and yields an approximately two-thirds weight reduction. Though costs would have been similar, because aluminum costs considerably more per pound, we also chose aluminum because of its workability – it forms and finishes much better than steel – and better withstands the elements and retains more paint.

The cutting edge

The marquee came to life in Poblocki’s routing department, where an 8 x 20-ft., Multicam 5.5-HP, 409 CNC router, with a hold-down, vacuum function, cut the aluminum into the required, angular shapes. After this step, Poblocki’s 14 skilled, journeyman, sheetmetal workers buffed, drilled, sawed and welded the structure. We shipped the main marquee in six pieces and fabricated various pieces to construct the soffit under the building’s canopy, top and side trim. In both areas, Poblocki uses a state-of-the-art, dust-collection system to maintain air quality for employees.

Next, fabricators ground and washed the sign with dual-action sanders, air files and a phosphuric-acid wash to eliminate any scratches or imperfections to prep the aluminum for painting. We used environmentally friendly Akzo Nobel black and silver paints, which resemble the same hues found in the original marquee. These paints were “green” because they contained high solids and low, volatile-organic compounds (VOCs). This is standard procedure at our facility.

The Poblocki team painted the sign in a 22 x 46 x 18-ft., JBI Inc. down-draft spray booth. The booth can be split in the center to create two, 25-ft.-sq. painting areas – each area contains an air-flow unit that can be set to a bake cycle to ensure rapid paint curing. Air filtration ensures a dust-free finish.

From there, staff electricians wired power and illumination into the sign with Signatrol #30S5 and 24-B-44 flashers that controlled GE incandescent lamps and 12mm, ruby-red neon, which Poblocki fabricated for the letters, and 15mm, ruby-red argon, which the shop used to create border tubing. All told, the sign comprises 274 lamps and 306 linear ft. of neon and argon. For servicing, Poblocki created strategically placed, removable covers and angle retainers that allow access to lamps, bulbs, housings and transformers.

AdvertisementAfter 550 manufacturing man-hours, the components were ready for installation. The existing theatre, which had unevenly settled over many years, was quite a bit out of square and plumb. This created some unique installation challenges. The building resides on the town’s narrow, heavily traveled Main St., and the sign overhangs the sidewalk.

Poblocki’s operating equipment, which facilitated installation, included a 120-ft. crane, two transport trailers, twin, 60-ft.-reach ladder trucks and an auger truck. The three-man team completed the installation in one week.

Happy endings

Today, the Rivoli Theatre again looms as a small-town treasure – the last remaining single-screen theatre in Oconomowoc County. The 280-seat cinema has returned to its 1930s opulence, complete with a marquee like those that greeted moviegoers in the first half of the 20th Century. At $3 per adult, the theater offers throwback ticket prices as well.

Poblocki proudly continues its longstanding tradition of movie-marquee fabrication, a key component of its 75-year legacy. As the sign industry continually evolves, one constant remains – every type of business profits greatly from beautiful, on-premise signage.

More About Jerry

Except for a two-year stint in the U.S. Navy during World War II, Jerry Poblocki has worked in the sign business all of his adult life. During the war’s early years, Jerry still contributed to his father’s sign business. When discharged from the Navy in 1946, he worked full-time for his father’s shop – Poblocki & Sons Co.

As a permanent employee, Jerry attended night school at Milwaukee School of Engineering to enhance his skills. Working mostly in the company’s electrical department, he was responsible for wiring and servicing signs. In 1953, Jerry became service and installation manager and was then promoted to estimator. In the ’60s and ’70s, he managed some of the company’s largest accounts, such as A&P, General Motors, Ford, Target, Shell Oil and many more. In 1982, Jerry and his son, Mark, purchased the company, and, in 1999, they sold it to its present management.

Today, the company, now known as Poblocki Sign Co., owns a 110,000-sq.-ft. facility in West Allis, WI, which it built in 1994. Jerry Poblocki serves as chairman of the board and as a consultant and manages the company’s theater sector and other specialized accounts. In his spare time, Jerry enjoys golf, but says it will never be as appealing as the work he does for the signage industry.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Advertisement

Subscribe

Magazine

Get the most important news

and business ideas from Signsofthetimes Magazine.

Advertisement

Most Popular

-

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo1 week ago

Paula Fargo1 week ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal6 days ago

Real Deal6 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Projects6 days ago

Projects6 days agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Alicia Brothers