Design

The Design

Unify your design to achieve your objectives

Published

18 years agoon

Last month, this column addressed the first aspect of the design process – the site survey. This column will focus on the second component — formulating the design plan.

The site survey is followed by a design packet and estimate request, usually provided by the salesperson. The design and estimate request can be printed on an envelope and include the business's name, billing address, sign location, key contact person, phone and fax numbers, Website and e-mail addresses. Add a date-and-time stamp that denotes when the design comes "in" and "out" of the art department. State the budget, which will determine the complexity of presentation materials and subsequent manufacturing materials.

- Most projects are designed sequentially. That linear progression can help you plan your projects from the start by examining basic design criteria. Ask the following questions:

- What are the project's basic parameters? Does it have a single, double or triple face? Is it a pylon, building mount, canopy, message center, time-and-temperature, stock ticker, attraction board? Or is it a reface of an existing display? Does it have individual letters?

- What sign materials are needed? Is polycarbonate, acrylic, high-impact acrylic, flexible-face or a composite material most suitable? Is a metal, stainless-steel, or aluminum back-up required?

- How will the sign be illuminated? Options include high-intensity discharge, high-output (800mA), neon, cold-cathode, LED and fiberoptics. If it's an electronic-message center, will lamps, LEDs or disks be used?

- What are the extra elements? Remote transformers? A raceway, A-frame or beam?

Check to see if the necessary materials — photo, logo, site plan, survey and color samples — are enclosed in the design envelope. Does the envelope include camera-ready art or material samples? The salesman should collect the letterhead, envelopes, annual reports, brochures and any information to assist the designer. Remember, the goal is unity of design.

Photos should show the architecture of nearby buildings and surroundings. Many new-project photos show an empty lot. Nevertheless, a photograph of the installation location is still important because the estimator needs to know if concrete or asphalt must be removed and determine the progress of the construction.

While serving as a sales manager at a company, I noticed the photographs didn't seem to fit the location for one job. The salespeople had simply picked a shot of an empty lot along an undeveloped road from a small box of miscellaneous photographs. Later, a salesperson explained he submitted random photos because there were no specific submission guidelines — "It didn't say a photo of what." Several times, the installation crew showed up to install the project, and the client hadn't even broken ground.

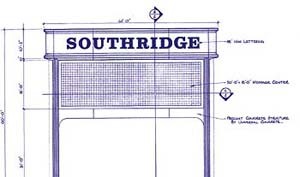

AdvertisementThe elevation drawing

Before the design department begins color renderings or models, the salesperson should approve the elevation sketches. This avoids wasting time on an obvious potential error.

When the salesperson makes the presentation, correct the drawing with a red pencil or pen. Designate each drawing and rendering "R-1," "R-2," etc., to indicate the latest revision. A half-dozen simple revisions isn't unusual at the birth of a major sign program. On such a program, the manufacturing supervisor will often review the project to insure the repeatability of a quantity project.

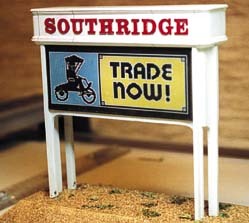

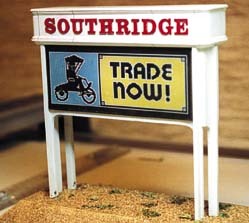

The sketch, rendering or model

Often a simple hand-rendered or Corel®-generated sketch is sufficient for a sign costing less than $1,000. A model may be prepared for a $1 million sign and perhaps even a fly-by computer software presentation for a multi-million-dollar project.

The model and the fly-by disclose 3-D and texture aspects. This might help you prevail over a lower bid that provides only a painted drop shading of a reveal or another feature. A graph paper box helps the salesperson sketch ideas.

AdvertisementOne company for which I worked, whose art department was overextended, simply transferred my dimensioned sketch on vellum with a company copy-block.

Does it sell?

Approximately 30 years ago, I was driving by Turner Signs of Provo, UT. A young man, Mick Steimle, was sitting on a stool, painting bulletin-enameled lettering. I observed his obvious talent and stopped to talk to him. He said he was completing a degree in art and art history at Brigham Young University.

I further asked what he was doing after graduation in a few months, but he said he didn't know. I gave him my card from Federal Sign and asked him to call me when he graduated. He did, and Federal Sign put him to work in their San Bernardino, CA, branch, near his parents. Mick became the design director of Young Electric Sign's Salt Lake City and Phoenix divisions. Simply stated, Mick's designs sold! They had readability and attraction.

Some designers have a specific talent. Arthur Solis, senior graphic designer at White Way Sign Co. (Chicago) worked for decades designing scoring systems, starting his career at American Sign & Indicator Corp. (Spokane, WA).

W. Duane Derfler, assistant division manager of Young Electric Sign Co.'s (St. George, UT), created work so distinctive, one could identify a sign as his. We simply called his ornamentations "taco blossoms."

AdvertisementDetailed Construction Drawings

After a customer approves the prints, detailed construction and engineering drawings are produced. One company had the habit of manufacturing the project, measuring it and then making the construction drawings. Whereas construction drawings were due in 10 days to the customer or the architect/engineer for approval before manufacturing, the company simply submitted them on Day 73 of a 75-day completion cycle, just before installation.

When message centers were to be flush mounted, the drawings weren't approved as submitted, so the cabinets had to be un-skinned, the back corner frames mitered and re-skinned. It was interesting to watch the client's publicly traded stock go from $17 to $3 a share.

I learned many techniques at Heath and Co. (Los Angeles). Wayne Heath was an extraordinary designer in his own right. His designers were held in the highest esteem (almost worshipped).

A designer is often assigned to a particular salesperson or customer. Heath's Raul R. Rodriguez of Los Angeles was my assigned designer. He accompanied me on many large presentations and continued to serve as a consultant when employed by another company. Raul is now the principal designer of Fiesta Floats (Pasadena, CA), which produces award-winning Pasadena Rose Bowl Parade floats for notables like Kodak, FTD and RainBird.

Full-size patterns

At Heath and Co., I observed customer approval of full-sized patterns. When Raul completed his design for the Las Vegas Flamingo Hilton, some proclaimed it was a "design that couldn't be built." James Lynch, P.E., vice president of engineering, and his department worked on a new scheme, which required full-sized patterns. We rented a local junior-high gymnasium because our upstairs pattern room wasn't big enough.

I brought this technique with me to Young Electric Sign Co. When sales manager, I invited Grace, owner of the Pearl Restaurant, to approve her Chinese-figure patterns on her signs. She burst out laughing and said that the unfortunate reverse stroke on one of the major figures "has something to do with urine!"

"As-builts"

Often, changes are made at the site. When boring the pylons, abnormal soil may force a foundation change. An "as-built" drawing facilitates additional accessories (such as electronic-message centers) at a later date and insures the service department has access. The as-builts become very important during a sign remodel or removal.

Design compensation

I remember visiting a Southern California company that didn't have a design department. I asked the sales manager how he could operate. He simply said he followed the salesperson from Federal Sign, San Bernardino, CA, (with its award-winning design department) out of his driveway and submitted bids on his design.

Most major sign companies accept this as a part of doing business. I advocate that if any of the materials are used, a customer must pay a 2% design fee. I have seen lower-bidding companies submit elevation drawings for permits that removed my copy block. When a client had the reputation of shopping my design, I simply numbered his copies. I billed and received the 2% fee. I have had designs made for clients who used them to receive financing but used the funds for projects other than signs.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

INX Releases 2023 Sustainability Report

4 of the Most Fun Sign Projects in Years

Sign Pro’s Phrase Coaches Customers with Bad Ideas

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Paula Fargo2 weeks ago

Paula Fargo2 weeks ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal2 weeks ago

Real Deal2 weeks agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Projects2 weeks ago

Projects2 weeks agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

-

Projects2 days ago

Projects2 days ago4 of the Most Fun Sign Projects in Years

-

News3 days ago

News3 days ago2024 Sign Contest Open for Submission

-

Business Management1 week ago

Business Management1 week ago3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

-

News1 week ago

News1 week agoPattison ID New Name of Five Companies