Dimensional Signs

Cutting Up in Big

Computerized Cutters Inc.’s Accu-Cut CNC routers

Published

18 years agoon

Everyone knows about Dallas. The Cowboys, once called America’s team, call this area home. One of TV’s most popular series was based there — who doesn’t remember J.R. Ewing?

Just north of the city proper is a community called Plano, the home of |2258|. Many of you may already be familiar with the company’s CNC routers and amazing Accu-Bend computerized, channel-letter machine.

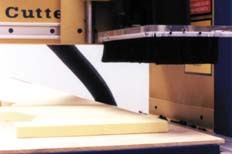

When we visited the facility to review the company’s new line of routers, the Accu-Cut X-series, we discovered a truly revolutionary, affordable and upgradeable product. If you’ve ever considered adding CNC capabilities to your shop, this is definitely a product worth considering.

Cutting down to basics

Basically, a computer program takes your design and converts those lines or vectors (a string or series of commands) into a language that a controller understands. These commands typically convey movements of a gantry, tool holder, or, in some cases, the material itself. The controller then takes these commands and converts them into signals that a power stepper or servo motors change into actual movements. Movement occurs in two or three different directions.

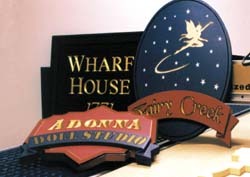

This machine’s signmaking capabilities are endless. For example, you can cut signboards into complex shapes using a router, when you might have been using a jigsaw before. Plus, the CNC is faster and more accurate. For relief carving, the proper software and Z-axis (downward direction) capabilities accomplish jobs easily. You can cut into a signboard to create engraved signs or fabricate dimensional letters and fancy ornaments.

Assets brought to the table

Computerized Cutters offers 4 x 4- to 10 x 25-ft. tables. The standard model (the 48) has a 4 x 8-ft. bed that handles most standard sizes of signmaking materials.

Perhaps the most important aspect of a CNC router’s design is the table used to hold down the raw material. The table should be sturdy, but more importantly, it should be true. The bed must be perfectly flat and level. If you’re engraving a board, the cut depth should be consistent. If the table is off, portions of the cut will be, too.

We were extremely impressed by the Accu-Cut X-series table. The folks at Computerized Cutters took particular care in the table assembly, with its rigid and solid-welded steel frame. Prior to assembling the table, Computerized Cutters meticulously mills the surface to insure it’s perfectly flat.

Signmaking in motion

The table secures the material to the router, but it’s the XYZ movements that transform a sheet of raw urethane, redwood or alloy into a beautiful sign. A rack-and-pinion system controls the X and Y positioning while the tool is in motion. This is more expensive than a cable system, but it insures repeatability and constant accuracy without adjustment.

The tool gantry (Fig. 1) holds the cutting tool and moves in the X (length) direction. It also accommodates the tool bay, which could be considered the "business end" of the machine. Motors in the gantry move the tool bay in the Y (width) direction.

The Accu-Cut uses dual motors in the gantry to insure substantial power and accuracy. When the gantry motors aren’t energized, it’s very easy to reposition the tool to its origin (0,0,0) by hand. This is a testament to the forethought used in manufacturing the machine. When beginning a job, it’s easier to manually position the tool to a home (origin) position and then use the computer controls for precise positioning.

Computerized Cutters obviously had precision in mind when it named its product line "Accu-Cut." The specifications call for an accuracy of 0.001 in. and a resolution of 0.0003 in., beyond what the eye can see.

The impressive tool bay contains the routing and cutting tools, and provides the Z-axis (depth) movement. The Accu-Cut uses dual threadscrews to provide precise movement. The bay can contain any one of many different tools. In most cases, a router is used.

For those wanting to use a quiet, variable-speed, highly reliable, spindle-type router, Computerized Cutters offers 3HP to 6HP Perske heads. The Perske spindles operate at speeds from 300 to 21,000 RPMs and are virtually maintenance free, although they require a 220V source (the Porter Cable is 110V). An engraving head is also available. This differs from the router heads in the size and precision of the bits.

The tool bay includes an integrated dust-collection connection (Fig. 2). An acrylic plate covers the cutting area when the router is plunged into the material, while a hose connects the plate to a vacuum source. These machines produce a lot of dust very quickly, so the dust-collection connection is a great feature.

Moving from the brawn of the Accu-Cut to the brains, we were somewhat stunned to find that the router doesn’t contain a classic controller. Typically, a CNC device has a processor that interprets commands coming from the routing software and then converts them into electrical pulses that drive the motors or servos that control the X, Y and Z movements. Usually, one interface controller board takes care of all the motors. If one of the channels fails, the entire board must be replaced.

The Accu-Cut uses the workstation and MaxMotion software to control the router. Commands are sent via the standard computer parallel port to individual driver cards in the router. If, for example, the X axis fails, you can simply replace one driver card, which is less expensive than purchasing an entire controller board.

3-D software in a 2-D world

The Accu-Cut is a true 3-D router. It produces elaborate relief carving effects — if you have the expertise, software and talent to produce such work.

As we’ve previously mentioned, the Accu-Cut works with MaxMotion software, manufactured by Solustan Inc. (Needham, MA). Although it has some graphics-creation capabilities, it acts as a virtual controller for the router. It converts graphic elements into commands the Accu-Cut understands and carries out.

Once the MaxMotion software launches, you have the router controls at your fingertips. Simple text and graphics are designed here and output to the router, or previously designed files can be imported from such application packages as Adobe Illustrator, Corel Draw or DXF files created from CAD or CAS programs. If you use a vector-based program and can prepare a DXF file, it’s probably compatible with MaxMotion.

The program allows for S-curve parameters, or, in essence, a ramp-up speed for the router. This includes jog speed and constant or maximum acceleration, which lets you take advantage of the Accu-Cut router’s fast speeds. You have full access to the router by using the control pad (Fig. 3).

When launching MaxMotion, the general screen appears with a tool palette to the left. The general commands are for entering type, drawing a frame, magnifying the area and moving up and down. A really good feature is the auto-layout function (Fig. 4). Specify the font, frame size and more, based on the material size loaded, then import the existing design. If it doesn’t fit the material parameters, the router won’t cut. You can adjust graphics and text to fit automatically by using the "Auto Layout."

The final window appears when the graphic is ready to be sent to the router. Here, all the parameters are specified for your review, and the standard parameters, like speed, depth and bit size, are automatically set. After you approve the specifications, the Accu-Cut begins its work.

Conclusion

Using the MaxMotion software, you should quickly feel comfortable setting up jobs. The Accu-Cut router engraves, routes and chisels in 2-D or 3-D, and accepts a variety of materials, including urethane, woods and metals. You can use the defaults or set up your own materials list.

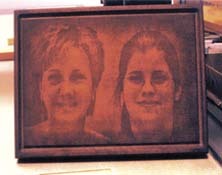

Large routed pieces (Fig. 5) can be produced quickly and accurately, one right after another, and precise images are also possible. Fig. 6 was routed and stained as finished artwork for a mantle piece.

Computerized Cutters’ Accu-Cut has set the standard for any signshop. This welded frame, coupled with accurate micro-stepper motors and solid head construction, provides pinpoint accuracy and fast cutting ability. If you’re in the market to buy a CNC router, consider the reasonably priced Accu-Cut. Your 2002 profits could increase with this money-maker.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Neon Museum of Saint Louis Holding Fundraiser

The Seasons of Sign Entrepreneurship

This Sign Company Absolutely Hates Price Shoppers

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Paula Fargo2 weeks ago

Paula Fargo2 weeks ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal1 week ago

Real Deal1 week agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Projects1 week ago

Projects1 week agoGraphics Turn an Eyesore Cooler Into a Showpiece Promo in Historic Plaza

-

Business Management1 week ago

Business Management1 week ago3 Things Print Pros Must Do to Build Stronger Relationships in the Interiors Market

-

News1 day ago

News1 day ago2024 Sign Contest Open for Submission

-

News1 week ago

News1 week agoPattison ID New Name of Five Companies

-

Manager's To Do5 days ago

Manager's To Do5 days agoMarketing Signs to Schools, Tradeshow and Quote Follow-up Make May’s List