News

Dog Days

Island Dog Signs serves diverse markets.

Published

17 years agoon

The partners who own Seattle-based Island Dog Signs come from different professional backgrounds. Kevin Jeffries opened a shop in his home, east of the Cascade Mountains in central Washington State, and Richard Lyon worked for a successful real-estate development firm in downtown Seattle. After Jeffries moved to Seattle at the millennium’s outset to capitalize on the city’s burgeoning economy, he met Lyon, who worked at the development firm with Jeffries’ wife.

Having realized they could synthesize their skills, they joined forces in 2003 and expanded their capabilities – particularly, Kevin’s varied fabricationskills and Richard’s understanding of processes and timelines that real-estate developers require.

Sound business

When he started his career in 1991 in Cashmere, WA, Jeffries created whatever sign types customers desired at any time. Primarily, this entailed banners, cut-vinyl graphics and hand-fabricated signage. In 2000, his move to a large city enabled a broader artistic repertoire and provided a very fertile market for the nascent digital-printing market.

Thus, Jeffries founded Island Dog signs; Jeffries chose the shop’s moniker because he lived on Vashon Island in Puget Sound near Seattle, and honored his family’s canine companion, Carabineer, a yellow lab.

AdvertisementAs his business grew, Jeffries knew a partner with specific contacts could unearth future markets. Enter Lyon.

“Richard’s experience with understanding the needs of contractors, engineers and others involved in real-estate development, punch lists, and the arcane language of standardized architectural and design/build contracts provides a tremendous benefit,” Jeffries said.

Presently, Lyon said real-estate clientele comprise approximately half of Island Dog’s business. Unlike other markets, where construction starts and real-estate prices have lagged recently, he said Seattle and neighboring environs have continually thrived – new corporate and residential high-rises continually dot the Emerald City’s skyline.

Typically, the construction of each new building represents many diverse opportunities, such as wrapping the construction site with large digital graphics, outfitting the building with the entry monument, directories, or suite and unit number; and, upon opening, various types of promotional graphics and sales or leasing banners.

The other half of Island Dog’s business includes many independent businesses, such as restaurants, bookstores and a wide array of retailers. The occasional savvy customer will walk through the door with specs and renderings in hand, but most depend on the shop for design direction.

Advertisement“Some customers are challenging because they struggle to make design-related decisions,” Jeffries explained. “But, no matter how resistant they seem, it’s important to turn around an initial idea quickly just to start the ball rolling. We always begin the process by specifying our best material solutions for the job, but we must occasionally value-engineer to meet the customer’s price range.”

The practice

Island Dog employs 14 full-time workers and operates within a 4,200-sq.-ft. facility. The shop uses Roland DGA Corporation’s EcoSol SC 540 and EcoSol SJ 745 EX eco-solvent-ink printers, an Arctic Titan cold-press laminator, MIG and TIG welders that produce its metalwork and the traditional complement of saws, drill and other woodworking equipment.

“We’re fortunate to operate within a thriving commercial area,” Jeffries said. “One hundred feet away from us, an architectural paintshop subs all such work for us. A few hundred feet in the other direction, a shop with a CNC router table handles that need. We also have arrangements with electric-sign fabricators, laser cutters, waterjet cutters and other specialists, all within our metro area.”

When Island Dog begins a site survey, Roth and Jeffries gather all pertinent job details. Though a 4 x 8-ft., double-post, real-estate sign may appear simple, he said such a project requires verification that underground utilities aren’t beneath the site, familiarity with its property lines and the area’s zoning and what sign types are permitted there.

He continued, “Seattle sign codes are somewhat restrictive; billboards and other off-premise advertising are tightly restricted. However, with onsite and marketing signage work, there’s enough gray area for us to function. We don’t fabricate grand-format digital prints, and the square-footage limits on architectural signage require efficient placement, but they’ve never posed a problem for us.”

AdvertisementBecause the company plies virtually its entire trade within the eco-savvy Puget Sound region, and many of it new-construction clients strive to meet nationwide Leadership in Energy and Environmental Design (LEED) standards, the company strives to use ecologically oriented materials and practices. In addition to printing with low-solvent inks, the company encourages customers to use such new-generation products as Klip Tech Composites’ (Hoquiam, WA) Paperstone™, a composite material made from recycled newsprint; Environ Biocomposites’ (Mankato, MN) Dakota Burl, which is made from sunflower-seed hulls; plywood/bamboo hybrids, such as Smith and Fong’s (South San Francisco, CA) Plyboo®; and metals, hardware and other materials that contain recycled material. Jeffries hopes that Matthews Paints’ (Pleasant Prairie, WI) VOC-free formulations begin selling in Washington soon – currently, they’re only available in California, which maintains the nation’s most stringent air-quality standards.

Case in point

Jeffries and Lyon enjoyed the chance to work for a very influential businessman. Vulcan, a commercial real-estate firm that Microsoft co-founder Paul Allen owns, is developing 60 acres of mixed-use real estate and hired Island Dog to fabricate an identification program for the South Lake Union Discovery Center, Vulcan’s 12,000-sq.-ft., onsite marketing facility.

The program posed significant time and logistical challenges – the shop had only 24 days from design approval to final assembly to turn around the program, and the site’s tight quarters allowed only an 18-in.-wide crawlspace to mount the 12-ft.-tall lightboxes within the architecture’s glass “curtain wall.” Island Dog fabricated the aluminum pillars from .125-in. sheet and coated with two Matthews colors.

To create the text, a waterjet cutter hollowed the aluminum, and acrylic backers comprise the verbiage. For the halo and backlighting, the shop uses 12mm-diameter neon tubing.

To accentuate the discovery center’s proximity to Lake Union, the shop angled the aluminum to resemble sailboats, a common recreational toy in the area.

What’s in store?

Island Dog has forged solid working relationships with dependable subcontractors and responsive clients. However, Lyon envisions subtle changes: “We’ve considered bringing electric-sign fabrication inhouse for some of our core clients, and I’d like to further promote the use of environmentally friendly products. We don’t try to be the cheapest, or the biggest, company. We prefer to work with clients who understand the need to balance effective graphics with the bottom line. If a company adds too many bureaucratic layers, it risks losing an understanding of its customers’ needs.”

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

What Makes the Perfect Sign Business Partnership

Marketing Signs to Schools, Tradeshow and Quote Follow-up Make May’s List

Church Sign Found After Being Stolen From Cemetery

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo1 week ago

Paula Fargo1 week ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers

-

Signs of the Times1 week ago

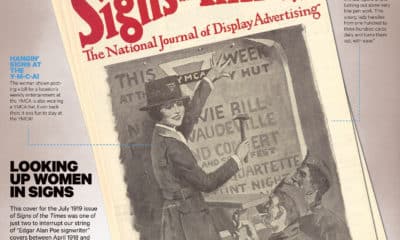

Signs of the Times1 week agoJuly 1919 Signs of the Times Cover Features Woman Installer