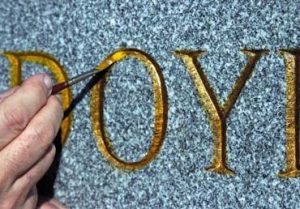

To hone gilding skills, get out of the shop and proceed to your nearest cemetery — yes, the cemetery. Gilding tombstones and monuments offers the chance to inhale fresh air in a serene, bucolic setting. Moreover, you’ll escape your normal hustle and bustle and, most importantly, perform work that pays well.

Getting started

First, contact nearby monument fabricators and inform them of your gilding capabilities. Don’t forget to present a portfolio of your work. Also, emphasize that, in this age of almost universal computerized, mechanized manufacturing, this elegant art is one of the few artistic skills that may be accomplished only with human hands.

The striking beauty of goldleaf, which greatly adds to a tombstone’s appearance, can be a decisive selling point to a deceased’s loved ones who seek your services. Don’t neglect to inform them of goldleaf’s durability. It adorned the tombs of the ancient Egyptian pharaohs and bottles used during the Roman Empire — and, the gold has largely remained intact. These attributes will allow you to command a respectable price for this timeless art.

In my opinion, the best way to establish a price for your work is to reference the "Gold Leaf" section in the latest edition of The Official Signwriters’ Pricing Guide (available from ST Media Group Intl.). As an alternative, incorporate your material costs into an appropriate markup as an hourly rate. In my market, I consider $75 per hour a reasonable rate.

In most cases, you’ll be asked to work on monuments already installed in the cemetery, though some jobs will require gilding within the shop. Either way, proper gilding techniques will almost certainly upgrade the stone’s appearance.

A new look

For this job, I was asked to gild a monument that had originally been decorated with imitation-gold paint. The craftsman who fashioned this older stone had made incised, V-cuts that differ from contemporary, sandblasted carving. Working with either type of stone carving is essentially similar, but incised letters allow the goldleaf a better reflection.

The first step involved sanding away the paint and smoothing the letters and cross with 120-grit sandpaper. After sanding, I dusted the carved areas, spritzed them with a water bottle and dried them with thick paper towels.

Next, I sealed the stone for size application. The late Rick Glawson, lovingly known as "Daddy Finegold" or "Dr. Finegold," once recommended shellac as the best way to seal and prime stone in preparation for sizing. It cures rapidly, creates a smooth surface and seals well. Thus, I’ve used Zinsser Bulls Eye shellac to gild all my tombstones.

When applying the shellac, mahl sticks or lettering quills are unnecessary; any overlapping letter edges can be easily corrected — I’ll explain this process later. Naturally, excessive shellac will make cleaning up more difficult. To prime and size the surface, I used single-stroke, red-sable brushes. The shellac’s drying and hardening requires approximately an hour, so this is a good time to eat lunch or read your latest issue of ST.

Down to size

After the shellac dried, the stone was ready for size application. LeFranc Charbonnel’s slow size is consistently durable, offers a lengthy tack window and yields a brilliant gild. A few drops of chrome-yellow 1Shot

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago

Paula Fargo1 week ago

Paula Fargo1 week ago

Real Deal1 week ago

Real Deal1 week ago

Photo Gallery1 week ago

Photo Gallery1 week ago

Projects1 week ago

Projects1 week ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Signs of the Times2 weeks ago

Signs of the Times2 weeks ago

Business Management6 days ago

Business Management6 days ago