DO YOU HAVE A UV flatbed printer? A textile printer? If you answered yes to either or those two questions then you really should own a finishing machine. “Finishing Machine” — that’s kind of a funny name. What does it finish? For the purpose of this article, a finishing machine is essentially a flatbed cutter. No, it is not a CNC router, but they closely resemble in operation and appearance. The main differences come down to the tools used to perform their jobs. Routers like to tear through rigid materials like sign foam, wood and some metals. Finishing machines work with more delicate materials like sign foam boards, cardboard, Coroplast and fabrics. So, when would you need one?

UV printers can print on a wide variety of media and a common one, as we mentioned above, is sign foam boards. It offers a rigid graphic fairly low in cost to the customer, who can use it for point-of-purchase displays, tradeshow decorations and even swag for potential customers. If you have a UV printer then you know what we’re talking about. If the signs are simple shapes like rectangles or circles, you can crank out a lot of pieces in a day. However, if your customer wants a full-size display of an athlete or actor, you might be lucky to get a couple completely finished in a shift. Did you catch that? With a finishing machine, you only have to load the right tool and the board and bring the job over. The machine will cut out those pieces precisely for as long as you can correctly load the boards.

Products such as these specialty boxes can only be produced profitably using a finishing machine.

Products such as these specialty boxes can only be produced profitably using a finishing machine.

Now the other interesting use is for textiles. If you are making banners or simple shapes then you can pretty easily cut the shapes from the printed fabric. If you need complex cuts for patterns or odd-shaped flags or awnings or what have you, then you have the same issue the UV flatbed folks have. Finishers can use either knives or lasers to cut fabric. But when you use a knife, the edges might not be sealed and as you know, fabric can fray.

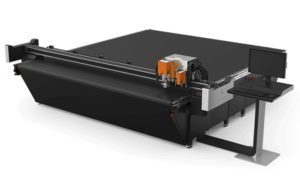

So how do these work? It really depends upon the materials you want to work with and the amount of automation you need. The machines are essentially 2D CNC routers that use a different set of tools. For example, they include knives made for particular materials such as fabric, foams or plastic. Specialty tools can be used to crimp or score for more dimensional displays. Programming the software determines where the cuts, scores and perforations occur. The images are printed with registration marks that a camera will detect. Simple machines may rely on fully manual processes like loading/unloading boards and changing tools. Many of the higher-end finishers might add automation in stages, including automated tool carousels and even robotic arms that load and unload the boards.

Finishers can be found as small as 2 x 3 in. on up to double-board configurations. Some machines use lasers for fabric work and standard finishing tools for rigid work. You can even find finishers that accept a small router for light-routing work on wood, etc. Conversely, some CNC routers include vision systems and finishing tools that let you use the machine for full-blown CNC routing as well as finishing work.

Finishing machines are extremely versatile and allow your shop to really leverage the power of your UV and/or textile printer. The accuracy and speed can’t be matched by an employee. Finishing machines open markets to high-volume customers, serving as the cherry on top of a well outfitted shop.

PHOTO GALLERY (6 IMAGES)

Advertisement

Tip Sheet2 weeks ago

Tip Sheet2 weeks ago

Photo Gallery4 days ago

Photo Gallery4 days ago

Ask Signs of the Times6 days ago

Ask Signs of the Times6 days ago

Real Deal2 weeks ago

Real Deal2 weeks ago

Paula Fargo1 day ago

Paula Fargo1 day ago

Benchmarks1 week ago

Benchmarks1 week ago

Photo Gallery1 day ago

Photo Gallery1 day ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Products such as these specialty boxes can only be produced profitably using a finishing machine.

Products such as these specialty boxes can only be produced profitably using a finishing machine.