Dimensional Signs

How to Paint 3-D Signs Faster

Dave Sherby shows how colored resin can speed up your production time.

Published

18 years agoon

Looking for a way to reduce your sign-painting time in half? Believe it or not, Dave Sherby, SherWood Sign & Graphic Design (Crystal Falls, MI), has found one. What’s more, by minimizing his production time for 3-D, high-density urethane (HDU) signage, he’s also improved his profit margins on such jobs.

Background

Since its introduction to the sign industry, HDU has received praise from sign fabricators who appreciate its ease of lamination, ability to be easily sculpted and resistance to moisture, fire, heat and cold.

However, like any product, it presents a few fabrication challenges. For example, HDU’s closed-cell formulation — which, if looked at microscopically, resembles an egg carton — is filled with tiny holes and bumps that can trap dust generated during sandblasting and sanding.

Therefore, to create truly smooth HDU lettering, you need to sand the substrate, blow away the dust, apply a coat of high-build (high-solids) primer, re-sand the surface, blow away the dust, apply a second coat of primer, sand the surface again, blow away the dust, apply a third coat of primer, and then apply two coats of paint.

Sherby has found a way to speed up paint time by using a two-part epoxy resin he first discovered a few years ago. Formerly marketed by Signs of the Times (Delavan, WI) under the name TC Resin, the product has now been renamed Signshine.

Step-by-step

Using this product is quite easy.

After sandblasting the background of an HDU sign, leave the sandblast mask on the sign’s raised letters. Blow away as much of the sandblast dust as possible, then apply the requisite coats of high-build primer and latex acrylic paint to the background. When you’ve finished painting the background, remove the sandblast mask from the letters and borders, revealing the bare HDU in those areas.

Next, mix the two-part resin formula in a cup, using equal parts epoxy resin and hardener. Per the product’s instructions, stir the substance for two minutes.

Into this mixture, stir solvent-based lettering enamel. Very little paint is required to color the resin; the appropriate ratio is 1 teaspoon of paint for every 8 oz. of mixed resin.

Because paint mixed in the resin appears darker than it does in a can, use paint that’s a shade lighter than the color you desire. For example, if you hope to achieve a dark-green colored border, mix medium-green lettering enamel into the resin.

To make sure the resin/paint mixture has enough paint, apply a very small amount of it onto a newspaper. If the mixture is so opaque that you can’t read the newsprint, no more paint is needed. If you can read the newsprint through the colored resin, then add slightly more paint.

Your next step is to pour the colored resin mixture into a plastic bottle with a nozzle. Signshine comes with these bottles, which resemble plastic, picnic ketchup or mustard bottles.

Squeeze the colored resin out of the bottle and onto the raised, bare border or letters of the HDU sign, just as you’d squeeze ketchup onto a hot dog. You do not need to cover the entire area with colored resin. The resin will actually spread out, run to the edge of the area, stop and self-level. Because of surface tension, the resin won’t run over the edges unless you apply too much, or get it too near sharp corners of letters. (To be safe, try to stay 1/4 to 1/2 in. away from letters’ corners.)

If the resin isn’t spreading out adequately, use the handle of an X-acto knife, a screwdriver or your finger (wear rubber gloves) to push it into the uncovered areas. If the resin isn’t spreading into tight corners, wait until the resin begins to harden. Then, use the tip of an X-acto blade and carefully push the resin to the corner.

Sherby says some signmakers have successfully applied colored resin using a brayer roller. He’s had no luck doing so, however. "I either don’t get enough resin on the roller, or it runs over the edge of the letters," he explains.

Because the resin is mixed with hardener, it dries chemically within 24 hours. A humid atmosphere won’t slow down drying time.

Over the next month, you’ll notice that the resin will turn slightly amber, thus slightly darkening the paint color. But after this time period, the color will remain stable. It’s worth noting that not all epoxy resins stop darkening after a month, which is why they’re reportedly unsuitable for this type of application; some actually go beyond amber and turn to a brown or black color.

Many people have asked Sherby whether they should prime the letters before applying the colored resin. The answer, he says, is no. Because the resin is an epoxy, it actually bonds more tightly to the bare, cellular HDU than it would to a primed, smooth surface.

For your final resin-application step, spray the resin-coated area with a spritz bottle of denatured alcohol. This breaks the surface tension, allows any bubbles near the surface to pop and affords an ultra-smooth surface.

Interestingly, paint by itself is more prone to fading than paint mixed in resin. Resin actually maintains its gloss longer than paint.

Colored resin can even be used for small, tight lettering..

Apply several beads of the colored resin to the sign’s border. It will eventually spread to cover the area and self-level. Before applying the resin, you may wish to paint the border’s edges, because here, where the resin is thinnest, you can sometimes see through to the bare high-density urethane (HDU).To create a marble effect, apply resin mixed with dark paint. Then, "swirl in" resin mixed with lighter paint. Note: Don’t mix up two separate batches of resin for dark and light colors. Use the same batch of resin for both colors.

Tips and tricks

Sherby offers other tips and tricks for using the resin product:

- Be sure to mix the resin and hardener in a flexible, plastic container. As the leftovers in the container begin to harden, you can squeeze the container, and the remaining mixture will pop away from the sides.

- The resin is thinnest near the edges of a border and letters. Sometimes, it’s so thin that you can actually see the bare HDU underneath. To prevent this from happening, first paint the edges (1/8 in.) with the color you want that area to be.

- Once applied to a sign, colored resin will adequately set up within 24 hours. However, if you apply clear resin to the sign — and you hope to paint or gild over the top of it — wait 48 hours before doing so. Sherby says the smooth resin provides an ideal surface on which to apply goldleaf. While some signmakers double-gild HDU to avoid holidays that may appear, a second layer of gold isn’t necessary over the resin.

- One person can usually apply 10 oz. of resin to a sign before it becomes too hard, and thus, unworkable. As such, don’t mix up any more than that amount of resin, if you’re working alone.

- If you have a large area to cover with the resin, note that the two batches of resin will never be exactly the same color. It’s better to apply a thin base coat of resin over an entire area, and then apply a second coat over the top of that same area, than it is to apply two coats side-by-side; they’ll never quite match in color where the two coats touch.

- To create a marble effect in the resin, apply one coat of colored resin onto your lettering. Then, take a resin mixture of the second color and, using the nozzle tip, swirl it into the first.

- The resin is not limited only to HDU. Sherby has also successfully used it to refurbish a redwood sign. Plus, he has used it on Alumalite

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Michigan Residents Make Parodies of Viral Detroit City Sign

What Makes the Perfect Sign Business Partnership

Marketing Signs to Schools, Tradeshow and Quote Follow-up Make May’s List

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo1 week ago

Paula Fargo1 week ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers

-

Signs of the Times1 week ago

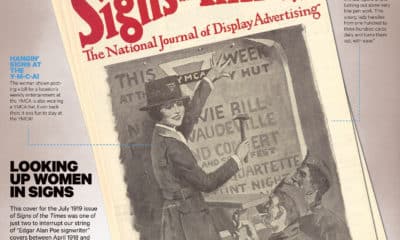

Signs of the Times1 week agoJuly 1919 Signs of the Times Cover Features Woman Installer