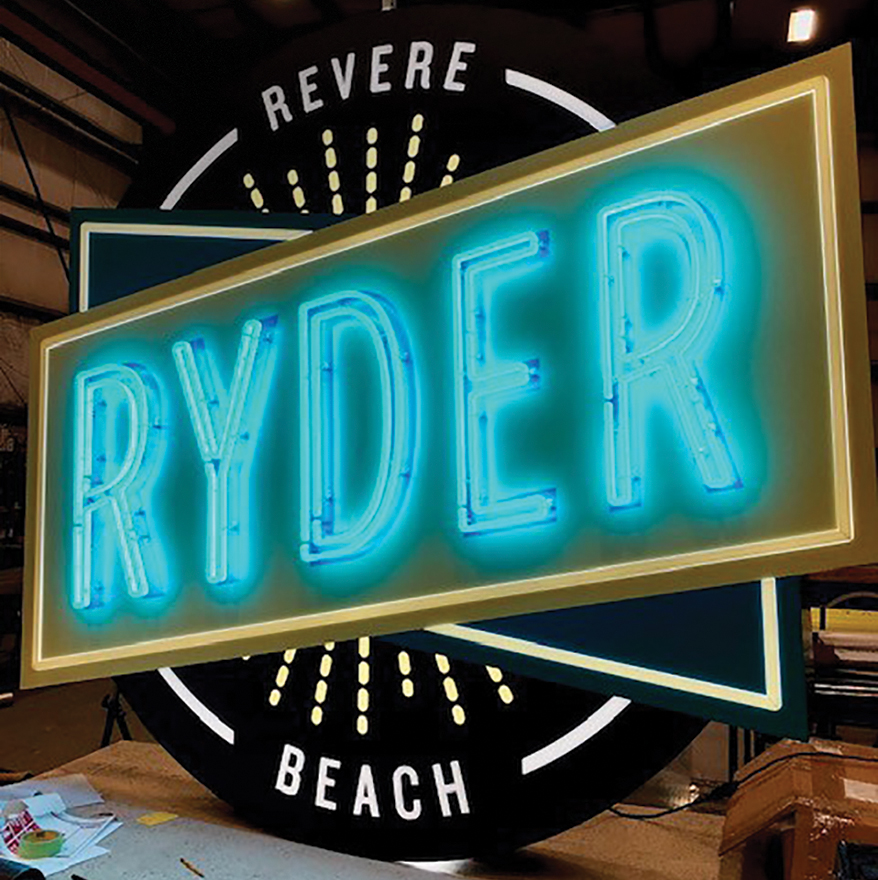

AS FRESH AS A cool ocean wave on a hot summer day, faux-neon (often called LED neon) signs can capture the mystique of actual neon without such drawbacks as high electricity bills. In recent years, LED-module manufacturers have devised clever solutions that meet color, size and illumination requirements, making faux neon ever more flexible. With the outdoor signage created and installed by Metro Sign & Awning (Tewksbury, MA) for the beachside apartment complex Ryder in Revere, MA, it wasn’t these usual drivers, but the color of the sign and proximity to the beach that steered the project to faux neon.

“Our design, purchasing and sales staff met with all the LED providers trying to find the best size, spec and color match for the aqua color that Ryder specified. We ended up sampling the skeletonized neon product from Inciseon,” said Tom Dunn, vice president of sales and marketing at Metro. They chose faux neon because the beach sand and salty air pose maintenance concerns. The sign also sits low on the sidewalk in a heavily trafficked area where it could be vandalized. The look and feel of the Inciseon product, which was rigidly formed by Signature Signs (Westport, MA), provided the best answer.

Dunn said his company has worked with many faux-neon products, including those from GLLS (Silicone LED Neon Flex), Principal LED (Street Wrap and Street Wrap Flex), and SloanLED (ColorLINE border tubing, FlexiBRITE and LEDStripe). So how does one begin to choose? Not surprisingly, client budget is at the top of the list, according to Craig Wondrasch, Metro’s lead purchaser.

Color-changing capability can be important (and subject to regulation), and achieving the specific color the client wants can dictate the final decision. There are also logistical considerations:

- Fit: When a product is not pre-formed by the factory, signmakers are fabricating it to match a specific component of a sign and it must be cut, capped and wired precisely (some products are cut in 2-in. increments).

- Turning radius: Accommodating a tight radius with a flex product can be a challenge — and there are limits.

- Long runs: With a flex product, long runs can lead to sagging and loss of a tight line. The faux neon must be secured firmly. Securing mechanisms vary, too, from custom clips to hold the faux neon, to traditional neon-tube supports and wires.

Finally, Dunn said Metro receives regular requests for quoting faux neon in open-face channel letters, building and canopy accents, and indoor and outdoor signs. It looks like this wave is not cresting yet!

Editors’ note: For more examples of faux-neon led signs, see Benchmarks from the July issue.

Advertisement

Tip Sheet1 week ago

Tip Sheet1 week ago

Ask Signs of the Times3 days ago

Ask Signs of the Times3 days ago

Photo Gallery23 hours ago

Photo Gallery23 hours ago

Real Deal1 week ago

Real Deal1 week ago

Benchmarks5 days ago

Benchmarks5 days ago

Editor's Note2 weeks ago

Editor's Note2 weeks ago

Women in Signs1 week ago

Women in Signs1 week ago

Photo Gallery1 week ago

Photo Gallery1 week ago