Electric Signs

Livin’ La Vida Libre

Media 1 creates some spicy signage for a Cuban-themed, Orlando restaurant.

Published

15 years agoon

Dale is president and co-partner at Media 1 Identity Solutions (Longwood, FL).

Cuba Libre opened its third location in Pointe Orlando, an inviting collection of outdoor shopping, dining and entertainment venues across the street from the Orange County (FL) Convention Center, the nation’s busiest such facility.

The restaurant transports its guests to the now-forbidden island through an environment reminiscent of pre-Castro Old Havana. Cuba Libre offers lively music and late-night, Latin-themed floorshows, as well as an extensive selection of Latin cocktails and tantalizing Cuban fare. With an open-air setting, vibrant colors, exotic foliage and servers dressed in guayabera uniforms, the two-story, 20,000-sq.-ft. venue exudes tropical ambiance.

Media 1 Vice President Rick Ream worked with Cuba Libre’s design-development firm, Crown Advisory Group. Because this Pointe Orlando location mimics the signage and environmental-graphics program at the other Cuba Libre locations in Philadelphia and Atlantic City (new locations are also slated for Washington D.C. and Dallas), the design process moved smoothly.

AdvertisementAfter the typical back-and-forth design decisionmaking with the client and Pointe Orlando management, Media 1 created full shop drawings and stamped engineering schematics and submitted them to the City of Orlando for permit approval.

As typically happens when awaiting landlord and permit approvals, the construction of the restaurant had progressed far by the time we began sign fabrication. Cuba Libre’s grand opening loomed only 10 days away, so Media 1 faced the challenge of constructing and installing this $20,000 sign in nine days! No other signmaker has ever been forced to work with such a quick turnaround time, right (ha ha)?

Building time

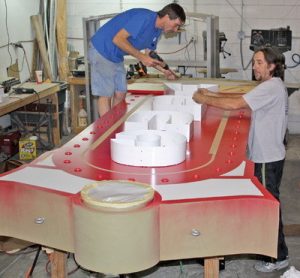

Given this tight time schedule, Media 1’s lead fabricator, Stephen Pass, assumed coordinating the sign’s fabrication. Working with our shop drawings, we developed full-size files in Corel Corp. CorelDraw! 10 and imported them to our 5 x 10-ft. MultiCam Inc. 3000 CNC router table. Using 0.125-in.-thick, 5052 aluminum, we built the approximately 6 x 15-ft., two-sided sign cabinet.

After the routing work, we moved the aluminum sheets over to the welding department. We cut the interior framework from 2-in.-thick aluminum angle and attached directly to the back sign panel with 3M Industrial Adhesives & Tapes Div. DP 810 epoxy and spot welds.

AdvertisementNext, we bent the sidewall to shape and welded it around the perimeter of the sign back. After having formed the sidewall around the entire frame and welded it into place, we created an interior cage of aluminum angle that would rigidly support the sign structure. Here, we added lifting points to aid bucket-truck installation.

Moving underneath the structure, Stephen centered and welded in four, 4-in.-sq., aluminum “legs.” These would serve as a telescoping mounting system that slides into a building-mounted framework during installation.

Now that our sign resembled an open shoebox, we attached the sign’s front face skin. We accomplished this completely with 3M DP 810 epoxy. The router pre-cut all socket holes and areas that would be internally illuminated.

Coats of many colors

Once we’d installed the sockets, we moved them to the spray booth. Using our Matthews Paint system, we sprayed two full, wet coats of PT Filler — a self-etching, metal primer — on all of the cabinet’s exposed surfaces. After having allowed 30 minutes for the primer to flash-cure, we applied three coats of satin-finish, bright-red of Matthews, satin-finish, urethane paint on the cabinet’s face. We decorated the remaining portion with the same, bright-yellow coating. For the vinyl graphics, we applied 3M Graphics Market Center Controltac media.

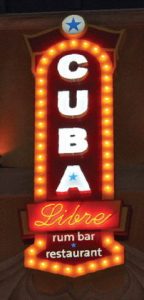

AdvertisementWhile our spray-booth operators decorated the sign, fabricators manipulated our Arete Corp. channel-letter-bending system to fabricate open-face letters that read, “Cuba.” We mounted the letters to the sign Tek screws, wired them with 38 ft. of double-stroke, 6500K, bright-white Voltarc neon and affixed Altuglas Intl. of Arkema Inc. clear, Plexiglas® acrylic faces on the letters. Following UL guidelines, we installed the sign with an external-disconnect switch.

Next, we mounted and wired two, 12,000V France, a Scott Fetzer Co. magnetic transformers into the sign’s interior to power all neon. After we’d masked the letters and all signface areas that would remain red with a plotter-cut, vinyl spray mask – we used Gerber Scientific Products Spraymask — we returned the piece to the spray booth.

Because we could stand the sign on its four legs, we easily situated the piece within the booth. The painters laid on their backs underneath the sign to assure full coverage. They applied four, bright-yellow coats. Because we’d committed to such a tight time schedule, we progressed from the initial primer coats to the final yellow topcoat in one (very long) day.

The fabricators left the shop at 9:00 p.m., with the sign still fully masked (and wet). They knew the install crew would arrive at 5 a.m. the next day to hang the sign. The coated sign face was fully cured and ready in time for the install. That’s one reason we use Matthews paint.

Bringing it home

We completed the install with our 65-ft. Altec bucket truck on Ford F800 chassis with a snorkel lift. The newly themed Cuban storefront was ready and waiting for its main identification.

To begin, we bolted the square-tube framework onto the building using thread and blocking behind the open wall. Next, we raised the 6 x 15-ft. sign structure with the bucket truck’s jib and slid the sign’s four legs into the receiving framework and bolted them together.

We installed the “Libre” skeletal neon panel onto the cabinet next and screwed the light bulbs – 43 Satco S 15w, clear sign bulbs — into their sockets. We finished the final electrical hook-up in less than four hours to complete our work.

Paired with Crown Advisory Group’s remarkable, exterior-building theming, Cuba Libre’s new sign adds allure to this unique restaurant, and provides a beacon of identification visible to a tourist-filled thoroughfare.

Thrilled with their beautiful new signage, Cuba Libre’s owners were equally impressed that we’d met their challenging schedule and contributed to a highly successful restaurant grand opening.

Equipment and Materials

Acrylic: Plexiglas® acrylic, from Altuglas Intl. (Philadelphia), (800) 523-7500 or www.plexiglas.com

Adhesive: DP 810 epoxy, from 3M Corp. industrial-adhesives and tapes division (St. Paul. MN), (800) 362-3550 or www.3m.com

Channel Letters: Channel-letter bender, notcher and flanger, from Arete Corp. (Denver), (800) 728-1453 or www.aretecorp.com

Coatings: Self-etching, direct-to-metal primer, available at building-supply stores; acrylic-polyurethane paint, from Matthews Paint Co. (Pleasant Prairie, WI), (262) 947-0700 or corporateportal.ppg.com/na/refinish/matthews

Installation: Bucket truck and snorkel lift, from Altec (St. Joseph, MO), (877) 462-5832 or www.altec.com

Lighting: Neon tubing, from EGL (Berkeley Heights, NJ), (908) 508-1111 or www.egl-neon.com; Two, 12,000V electronic transformers, from France (Fairview, TN), (800) 753-2753 or www.franceformer.com; Clear, 15W incandescent sign bulbs, from Satco (Brentwood, NY), (800) 437-2826 or www.satco.com

Plotter: VersaCamm VP-540 printer/plotter, from Roland DGA Corporation (Irvine, CA), (800) 542-2307 or www.rolanddga.com

Router: MultiCam 3000 CNC router, from Multicam Corp. (Dallas-Fort Worth Airport, TX), (972) 929-4071 or www.multicam.com

Software: CorelDraw® Graphics Suite X4, from Corel Corp. (Ottawa, ON, Canada), www.corel.com

Vinyl: Controltac™ film, from 3M Graphics Market Center (St. Paul, MN), (800) 374-6772 or www.3mgraphics.com; Gerbermask paint mask, from Gerber Scientific Products (South Windsor, CT), (800) 222-7446 or www.gspinc.com

More About Dale and Media1 Identity Solutions

Dale Salamacha, who serves as Media1 Signs’ (Longwood, FL) president and operates the business with partners Damon Coppola and Richard Ream, has worked in the sign industry for more than 25 years. He said, “I remember when a lettering quill and 1Shot [lettering enamel] were what you used to make a sign.”

Now, Media 1 employs more than 30 people, and has specialized in custom, commercial-sign fabrication and installation since 2000. Wrap This, Ink, a division of the company, designs, prints and installs vehicle wraps. The shop fabricates approximately 1,000 wraps and fleet graphics for businesses throughout the Sunshine State.

Nationwide food and entertainment companies, particularly food-court and shopping-center vendors, comprise the bulk of the company’s business. Clients typically seek custom, one-off designs that feature unique construction and lighting for identification and structural applications. Salamacha said, “We continually strive to create one-of-a-kind architectural features and signage that function more as artwork, than typical signage.”

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

PRINTING United Alliance Forms Strategic Partnership with ASI

The Joy of Working

5 Signs That Embody Care and Gratitude

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo7 days ago

Paula Fargo7 days ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks2 weeks ago

Benchmarks2 weeks ago6 Sports Venue Signs Deserving a Standing Ovation

-

Photo Gallery7 days ago

Photo Gallery7 days ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers