Banners + Awnings

Material Issues

Insights into banner advances and trends

Published

15 years agoon

Banners have come a long way from the days when the principal options entailed bulky canvas or old-school, cumbersome vinyl. And, the advent of digital printing has opened far more possibilities than the days of handpainted or cut vinyl. However, there remains no panacea substrate that suits all printing requirements and all environments. And, how will the economy impact the market?

Representatives from several banner-material manufacturers and purveyors offer insights into what improvements have aided the market, as well as what challenges lie ahead.

Ultraflex

Ultraflex (Randolph, NJ) offers myriad frontlit and backlit substrates, textiles and assorted specialty fabrics. John LoCicero, the company’s North American director of sales, said customers should research more than a spec sheet.

“Service providers often confuse weight with strength,” he said. “Tensile strength is much more important than density. We have some 13-oz. materials that are stronger than 15-oz. products. And, buying a fire-retardant product should be a top priority for any installation. Safety shouldn’t be ignored.”

AdvertisementAny successful banner installation requires solid hemming and fastening procedures. As an example, LoCicero referenced a hypothetical, 5 x 5-ft. banner: ”An application like this requires several pieces of seaming at key connection points; a hem down the middle, and a triple fold where the tether points will be anchored to the building. Stitching weakens the material a little bit, so it’s important to use a heavy, seat-belt-type material for the webbing.”

Although more printers offer double-sided banner-decoration capabilities, and they’ve become more common for pole-hung or suspended applications, he suggests proceeding carefully.

“Printing two-sided banners is difficult because you have to print the front and register the back to match registration and ink density,” LoCicero said. “And, you already have ink on the platen from printing the first side, which makes it prone to make the material soft and sticky. Ultimately, you use more material, so printing two single-sided banners and stitching them together might be a better option.”

The company introduced BioFlex, a biodegradable banner material, approximately two years ago. The eco-friendly product has gained traction with schools, government facilities and other institutions, as well as car dealerships. LoCicero said the company plans to introduce a mesh BioFlex version.

Value Vinyls

Last fall, Value Vinyls (Grand Prairie, TX) introduced EcoLogic™, a recyclable, plasticizer- and heavy metal-free banner fabric that’s polypropylene (PP) based and an alternative to traditional, polyester scrim. The company manufactures the 16-oz. material in widths up to 126 in. and coats the media with thermoplastic olefin (TPO), a PVC alternative. Value Vinyls rates the UV- or solvent-ink printable substrate for two years of outdoor use.

AdvertisementLorna D’Alessio, the company’s director of sales, said the company spent approximately 18 months developing the product.

“The environmental impact of PVC is well documented,” she said. “The market is demanding alternatives, and, even in tough economic times, I think the impetus for more sustainable alternatives will continue.”

According to the company, EcoLogic complies with recycling regulations as a Resin Code 7 material, which means it comprises more than one resin within a layered substrate. The product is recycled via a shredding the material, melting and extruding the remains, chopping the mixture and heating and molding it into a repurposed product, such as plastic “lumber” for outdoor decking.

National Banner Co.

National Banner Co. (NABCO) produces flags, banners, decals and related POP materials, as well as custom-decorated banners, and sells almost entirely wholesale within the industry. Traditionally, the company’s products have helped market car dealerships, but with that segment taking a nosedive –General Motors CEO Rick Waggoner proposed curtailing GM dealerships to 4,700 by 2011, down from more than 8,000 in 2000 – the company has adapted.

“Although the market for stock banners has declined, our custom business has remained fairly steady,” Marc Goldfarb, NABCO’s president, said. “In-store promotion and POP is still in relative demand because they provide visual impact without a huge upfront investment.”

AdvertisementThe company has also adapted its production process to meet market demands. He estimates dye sublimation decorates approximately 70% of the company’s banner products – he estimated they comprised 10% five years ago. Goldfarb said the increasing complexity of digitally rendered, CMYK banner artwork gibes with “dye-sub”’s capacity to produce fine detail. Goldfarb estimates NABCO prints approximately 60% of its banners on vinyl, and 40% on such textiles as poplin, canvas and polyester. The company produces its graphics on five Mimakis – JV5s for inkjet, and JV4 for dye-sub – and two AIT roller presses.

“Working with four-color process is also much more economical than using spot color,” he said. “Inkjet will continue to draw workload from screenprinting, and single-color [screenprinting] presses will be gone in five years.”

Cambridge Canvas

Cambridge Canvas (Cambridge, ON, Canada) converts banner material into rolls – in the U.S., their product is known as Bandanna — and offers custom, wholesale banners. Jeff Campbell, the company’s director of operations, correlates massive layoffs from large companies with an influx of novice entrepreneurs who’ve entered the sign business.

“Even in bad economic times, businesses will always need on-premise and promotional graphics,” he said. “Therefore, the sign business offers an attractive franchise opportunity to those who’ve been downsized. However, many will be unfamiliar with the quality of banner materials on the market, so they need to educate themselves about the best products to meet their needs.”

The company recently introduced Ready2Print, a 14-oz. blank, fire-retardant, roll banner media with pre-assembled hems and a proprietary, pre-finished grommet system. Campbell said market demands for greater banner-production efficiency spurred the product’s development.

“Deadlines and competition are getting more intense, so the ability to save labor required to grommet and sew a banner can provide a competitive advantage,” he said.

Britten Media

Traverse City, MI-based Britten Media, offers custom banners, inkjet-printable media and hardware. Paul Britten, the company’s founder and president, said his collegiate study of architecture informs his current occupation.

“When installing a banner, you have to understand the structure on which it’s installed,” he said. “A concrete well requires a very different package of hardware from one installed on Dryvit® [EIFS synthetic stucco] because of the strength of the surface. For a pole banner, you need to know its foundation.”

He also noted, although wind load – the velocity of air blowing directly on a sign’s surface – is a common consideration, he said wind compression – the force of wind blowing across or under a signface – is an often overlooked strain on a banner’s hardware system. For outdoor installations, Britten normally recommends using seatbelt-style webbing over rope hemming with triangular gussets.

The company’s hardware offerings include:

• Banner Saver™, a spring-loaded, wind-deflecting system designed for pole-mounted banners that mimics the human shoulder and rotates to stabilize banners amidst wind-load pressure;

• BannerDrop®, a hoist-and-mount system for hanging ceiling-suspended graphics up to 60 ft. high with a solid-state motor and remote-control system that raises and lowers banners up to 30 lbs.; and

• BannerStretch™, a stainless-steel framing system that contains a spring-supported tensioning device that pulls fabric taut to fit the frame.

Britten acknowledges it can be difficult to sell installations that require specialized hardware, but noted efficiency in managing long-term operating costs should remain a key priority.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

What Makes the Perfect Sign Business Partnership

Marketing Signs to Schools, Tradeshow and Quote Follow-up Make May’s List

Church Sign Found After Being Stolen From Cemetery

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo1 week ago

Paula Fargo1 week ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery1 week ago

Photo Gallery1 week ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers

-

Signs of the Times1 week ago

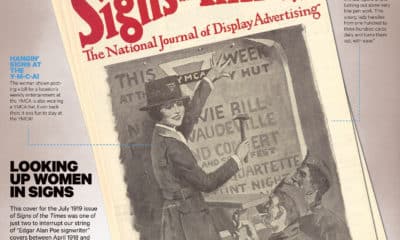

Signs of the Times1 week agoJuly 1919 Signs of the Times Cover Features Woman Installer