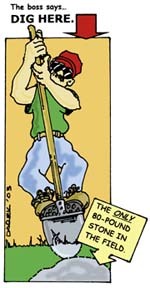

Generally, signmakers subcontract the excavation of large foundations, although the shovel, pick and post-hole digger still come into play with smaller signs. A pick or tamper-top posthole digger breaks up hard soil or dislodges smaller rocks up to the size of a football. You can also use a wrecking bar to pry loose smaller rocks, or place the tamper-top hammers behind larger rocks and pry them free once you dig around them. For cutting roots, try the tamper-top, a small hatchet, a keyhole saw or such tools as Milwaukee’s 18-volt rechargeable reciprocating saw. If you’re not experienced in digging and shoring large, excavated holes, let a professional do the work. Although many OSHA and other protective laws exist, you still read about cave-ins killing construction workers. During a cave-in, soil or rock material separates from the sides of an excavation in such quantity that it entraps — buries — a person. Don’t treat this lightly because cave-ins are usually fatal — it takes six minutes for the brain to die from suffocation. Shoring is a system of cross-braced poles (shores) with vertical planks (uprights) installed at each end (perpendicularly) that presses against the sides of the pit to prevent cave-ins. To envision this apparatus, recall Samson in the Philistine auditorium, pushing against the twin pillars “upon which the house stood” (Judges 16:26). See his outstretched arms as the shoring, his upturned hands as the planks, and the pillars as the sides of the excavated hole. If you’re excavating for a sign that requires a concrete foundation, plan to finish the excavation and concrete “pour” ahead of the sign. This allows you time for delays and any extra time for concrete curing. Hire a contractor for larger excavations — your core product is signs — and relieve yourself of the accompanying grief. You must provide the contractor with an engineering plan for the excavation, plus a schedule of completion and contract for the work. Hire a local engineering firm if you doubt your excavation-designing abilities. If the sign is going into a new complex, and because the sign base may need to be in place before any paving occurs, the general contractor may assume responsibility for the sign-base pour. This is a good reason for expediting the sign-foundation segment. Because of possible cost savings, Peter recommends auger-type excavations, although these, due to their narrower scope, need to penetrate more deeply into the ground than block excavations. Also remember that bell-shaped foundations — those wider at the bottom — are more efficient. The density of the neighboring soil determines the earth-resistance of the foundation base when lateral stress, such as that caused by wind, is applied to the sign’s fulcrum point. Because earth weighs less than concrete, and because the sign is, in form, a sail, the neighboring earth’s density greatly impacts foundation design. If you’re worried, talk to a soil engineer. If you’re just concerned, once the framing is removed, fill and power tamp the area between the cured concrete and undisturbed earth with appropriately sized gravel. When bidding for a sign requiring excavation, your biggest fear should be “unsuitable ground material,” that is, a soil or aggregate that doesn’t adequately support the foundation structure. Water saturation is the most common culprit. A simple test is to slowly drive the front wheel of a heavy vehicle onto the site. Stop if the moving tire sinks or causes a waterbed-like rolling on the ground surface — this indicates an undesirable level of water saturation. Because such soil won’t support the sign foundation, you must remove and replace it with an equal amount of substantial, compactable soil. You’ll also want to know the source of the water. Before you bid its removal, determine if the undesirable material is below the project’s grade level. If it is, the grading contractor, when he cuts the existing soil to the new grade level, will remove some of the above-grade soil. Check with him first, but removing a layer of soil lessens your overall removal costs. If you need grading information on the job site, you can read it from the surveyor’s stakes. Look for the “Hub” and “Information” stakes near your part of the site; then, nearby, find one with “RS” (reference stake) written on the top and numerals below. The first-level top numeral, shown over a drawn slash, is the stake’s elevation (as it relates to the marked Hub stake); the bottom numeral is the distance, in feet and tenths of inches, to the end of that particular cut. As an example, C-1.1/2.1 (“C” indicates “Cut”) tells you the C-1.1 cut will be 1 ft. 1/10 in. below the level of the hub stake, and 2 ft. 1/10 in. from the hub stake. In this case, (again, you’ll want to check it with the site engineer), the first 1.1 ft. of unsuitable material is removed by the grading contractor. An “F,” instead of a “C,” indicates “Fill.” Thus, a stake reading F-1.1/2.1 says to fill 1.1 ft. You’ll want to talk to the site engineer regarding this, too, because, by adding fill, he’s adding to your unsuitable materials-removal costs.

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago

Paula Fargo2 weeks ago

Paula Fargo2 weeks ago

Real Deal1 week ago

Real Deal1 week ago

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago

Projects1 week ago

Projects1 week ago

Women in Signs2 weeks ago

Women in Signs2 weeks ago

Signs of the Times2 weeks ago

Signs of the Times2 weeks ago

Business Management7 days ago

Business Management7 days ago